A method and system for cleaning and filtering lye nanofiltration membrane

A technology of nanofiltration membrane and lye, which is applied in the field of cleaning, can solve the problems of no clear indication of cleaning results, mediocre cleaning effect, time-consuming and labor-intensive problems, and achieve the effect of changing cleaning methods, reducing operating costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

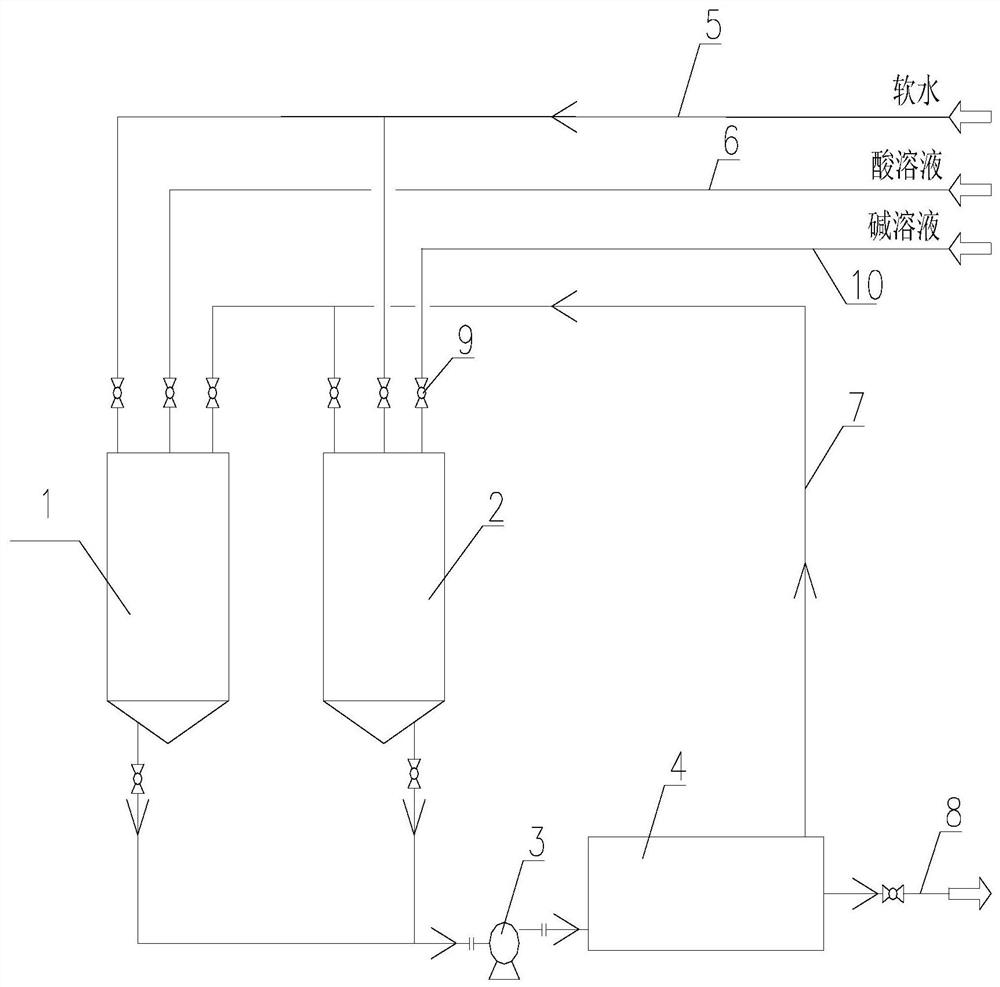

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] The production of viscose staple fiber includes the purification of squeeze liquid and the concentration of hemicellulose. The purification of squeeze liquid includes the removal of hemicellulose and other macromolecular substances in the squeeze liquid to obtain relatively pure lye; the squeeze liquid is viscose Produced in the short fiber production process, it needs to be filtered by nanofiltration membrane before being used in production. The concentration of hemicellulose includes cross-flow filtration of lye through nanofiltration membrane to obtain lye with high hemicellulose content; the squeezed liquid enters the nanofiltration membrane through a high-pressure delivery pump, and is driven by pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com