An ultrasonic physical aeration cleaning system

A cleaning system, ultrasonic technology, applied in the physical field, can solve the problems of running stability and lack of practicability, a small number of dishes to be cleaned at one time, and the overall effect is not ideal, so as to avoid laborious and time-consuming cleaning, easy to clean and handle, Stable and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

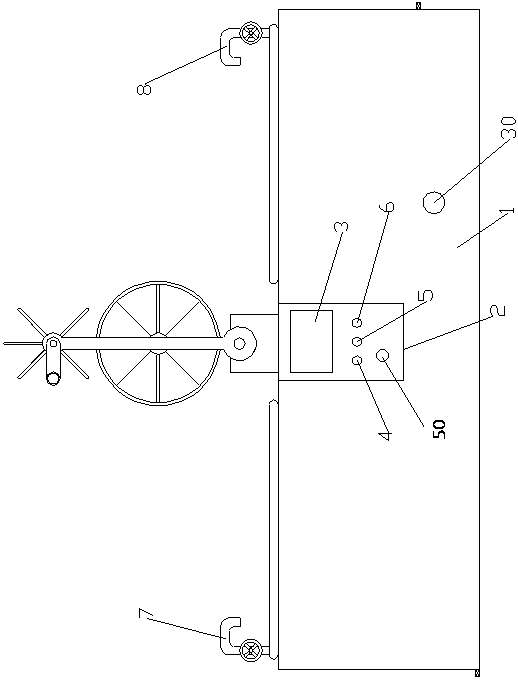

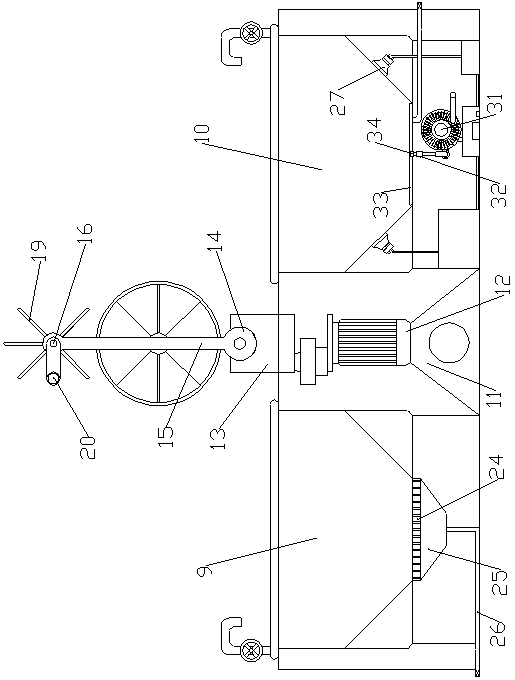

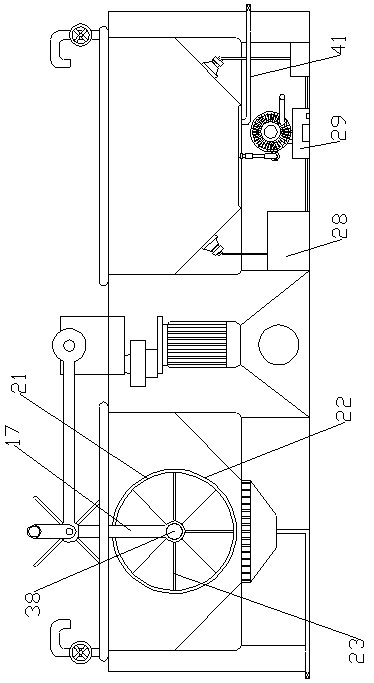

[0026] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, an ultrasonic physical aeration cleaning system, including a housing 1, a pre-washing device and an ultrasonic aeration cleaning device are installed on the housing 1, and the pre-washing device The middle part of the ultrasonic aeration cleaning device is provided with a turning device, and the outer side of the housing 1 is equipped with a control box 2 connected with the ultrasonic aeration cleaning device and the turning device.

[0027]Described pre-washing device comprises the pre-wash pool 9 that is installed in housing 1 inside, and the top of pre-wash pool 9 is equipped with pre-wash faucet 7, and the bottom of pre-wash pool 9 is provided with filter screen 24, and the bottom of filter screen 24 is provided with The water collecting bin 25, the bottom of the water collecting bin 25 is equipped with a pre-washing outlet pipe 26 with a valve, the pre-washing tank 9 is installed on the inner side of one end of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com