Quick-flushing and quick-discharging groove for integrated circulating cooling and cleaning of semiconductor wafer

A cyclic cooling, semiconductor technology, applied in the fields of fast flushing and fast discharging, and semiconductor wafer processing, it can solve the problems of surface residue, damage, uneven cleaning, etc., and achieve the effect of cleaning the wafer thoroughly and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

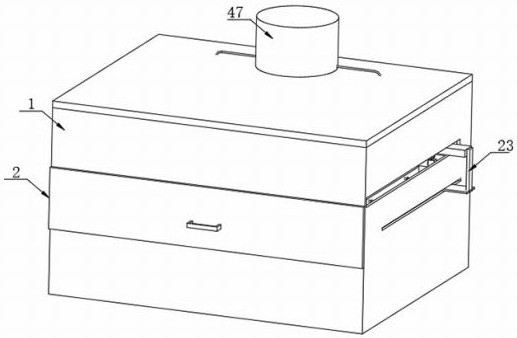

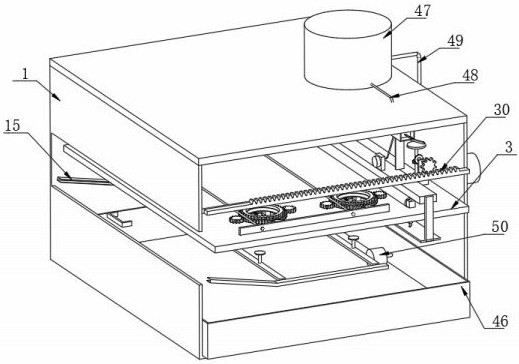

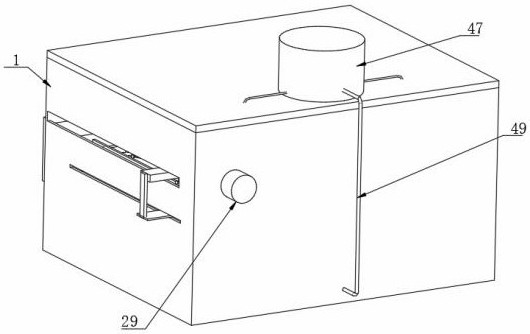

[0039] The embodiment of the present invention provides a quick-flushing and quick-discharging tank for integrated circulation cooling and cleaning of semiconductor wafers.

[0040] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 15 , including a cleaning tank 1, the outer side of the cleaning tank 1 is rotatably connected with a cover plate 2, both sides of the inner wall of the cleaning tank 1 are fixedly connected with sliding frames 52, and a fixing plate 3 is arranged between the two sliding frames 52 and is slidably connected with the fixing plate 3 , the top of the fixed plate 3 is provided with a plurality of through grooves 4, the top of the fixed plate 3 is provided with a placement groove 56, and the plurality of placement grooves 56 are distributed around a plurality of through grooves 4 and communicated with the through groove 4, and the top of the fixed plate 3 is provided with A plurality of rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com