Stamping die of side flanging of automobile cover

A technology for automobile panels and stamping dies, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex mold structure, high mold cost, inflexible movement, etc., and achieve small mold volume, compact mold structure, flexible action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

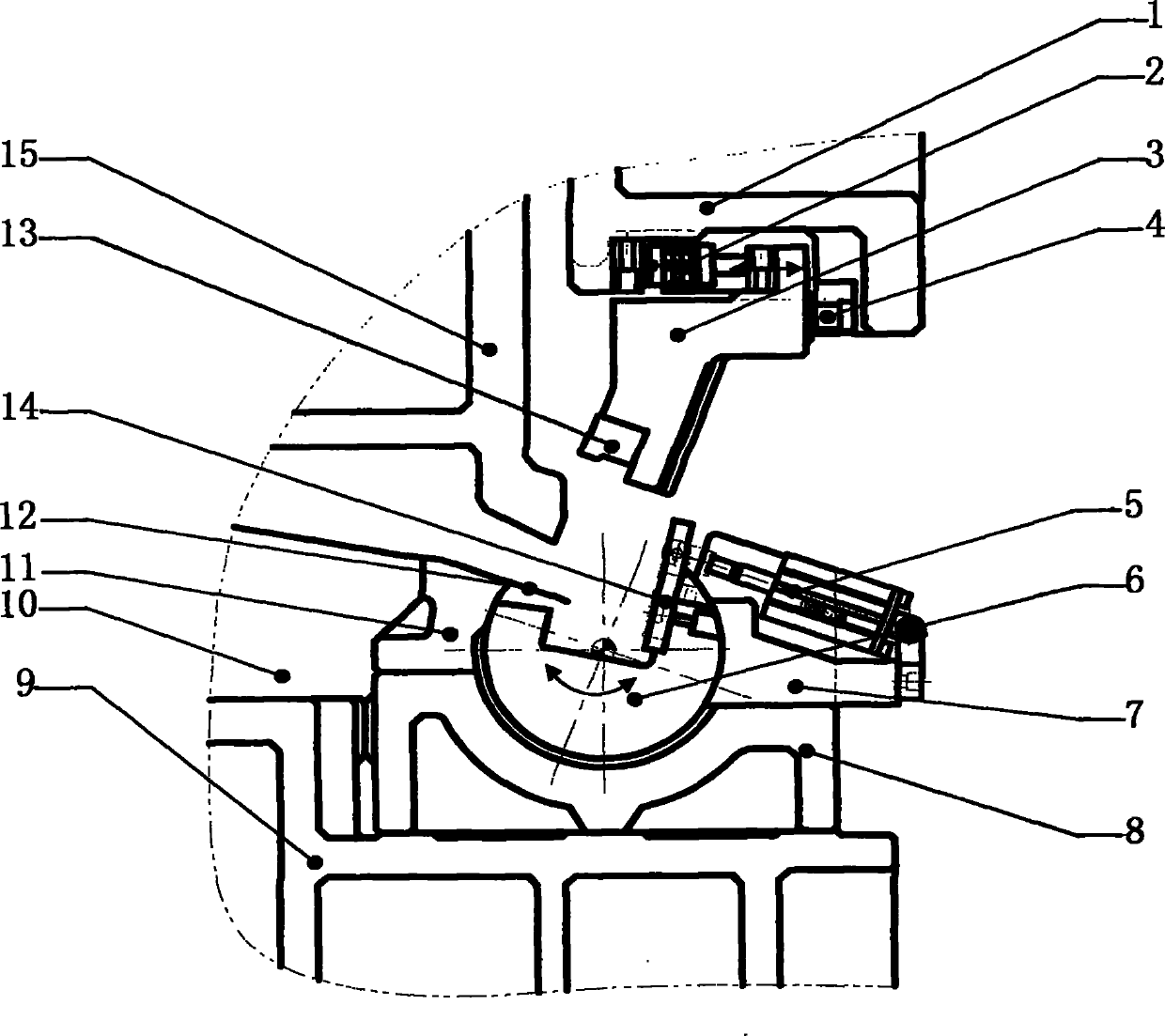

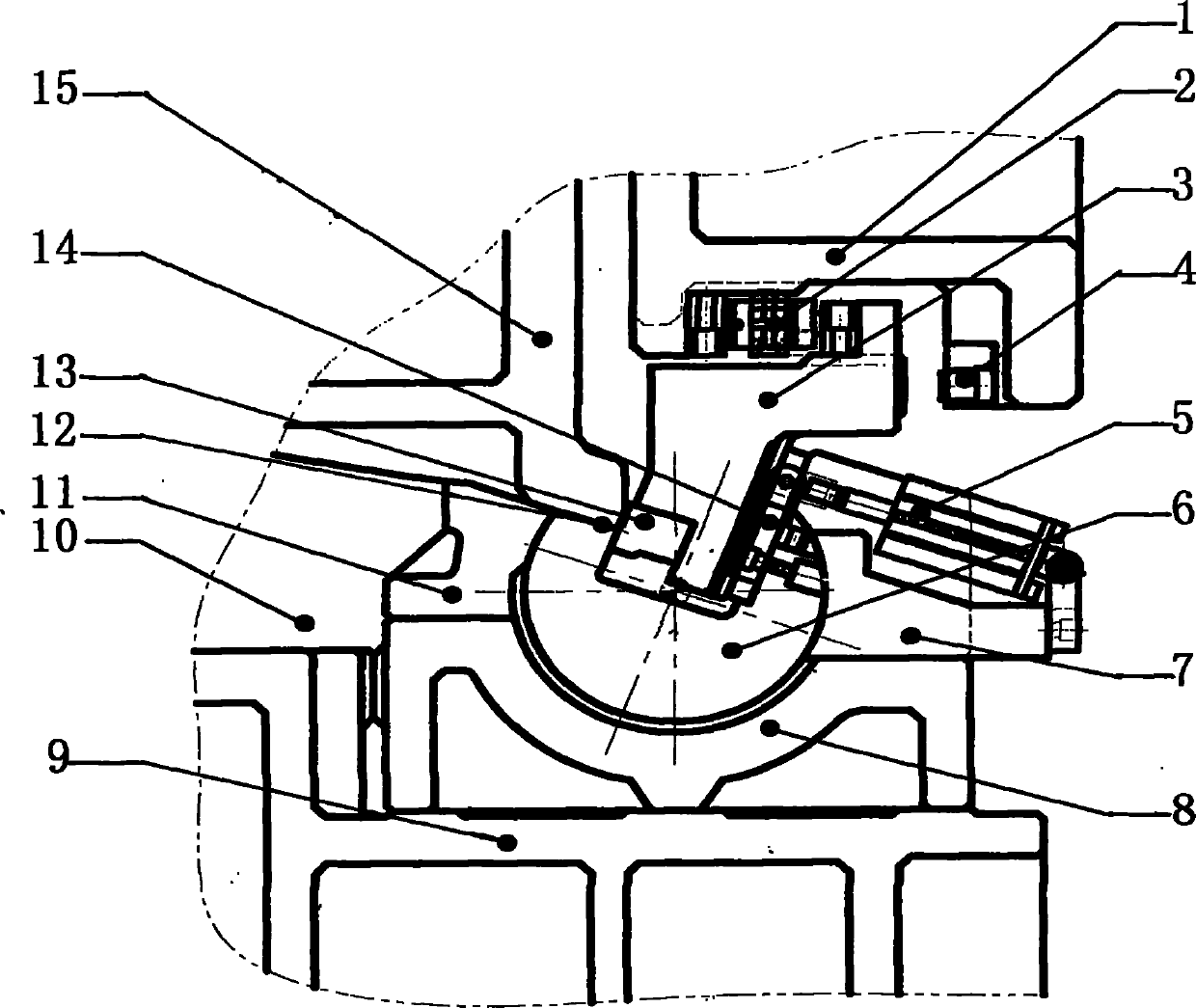

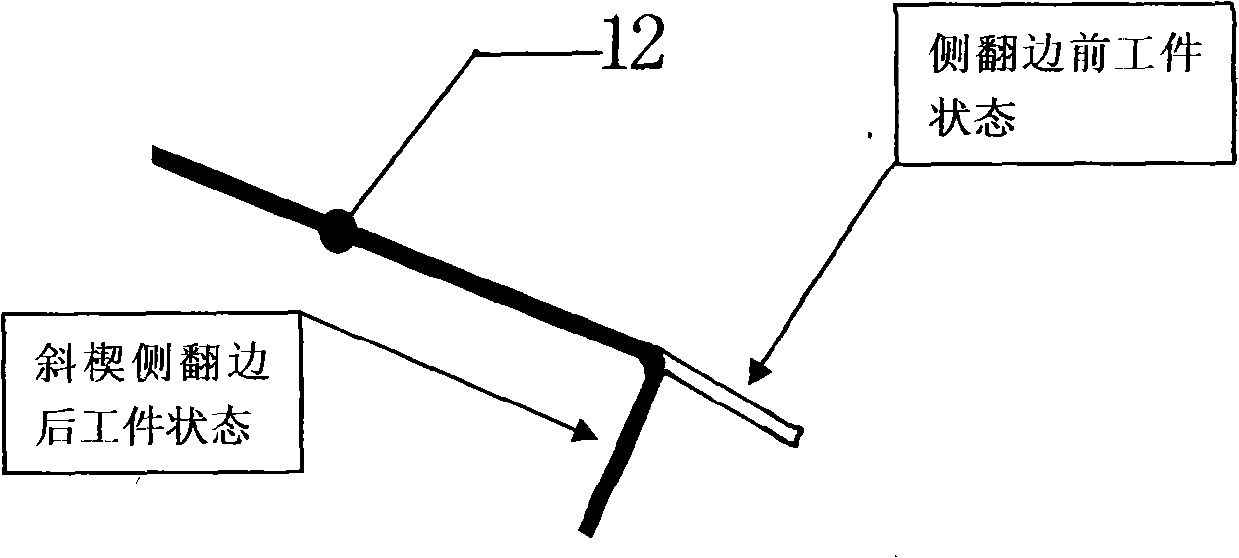

[0016] Below in conjunction with accompanying drawing and working process, the present invention will be further described.

[0017] see figure 1 A stamping die for the side flanging of an automobile panel as shown, comprising an upper mold base 1, a lower mold base 9 and a presser 15 installed in the upper mold base;

[0018] A nitrogen gas spring 2 is horizontally arranged in the groove at the lower end of the upper die base 1, the left end of the nitrogen gas spring is connected with the left side wall of the groove, and the right end is connected with the support block at the upper right part of the wedge slider 3; a limit block 4 Set on the right side wall of the groove at the lower end of the upper die base, the limit block corresponds / contacts with the side wall of the upper right part of the wedge slider 3; a flanging knife block 13 is set on the left side of the bottom of the wedge slider 3 ;

[0019] A wedge mounting seat 8 with a circular arc groove in the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com