Machine tool specially for processing gate valve body sealing seats

A special machine tool and sealing seat technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low labor productivity, time-consuming and laborious, competition, etc., to meet the angle requirements, reduce manufacturing costs, and facilitate installation. card effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

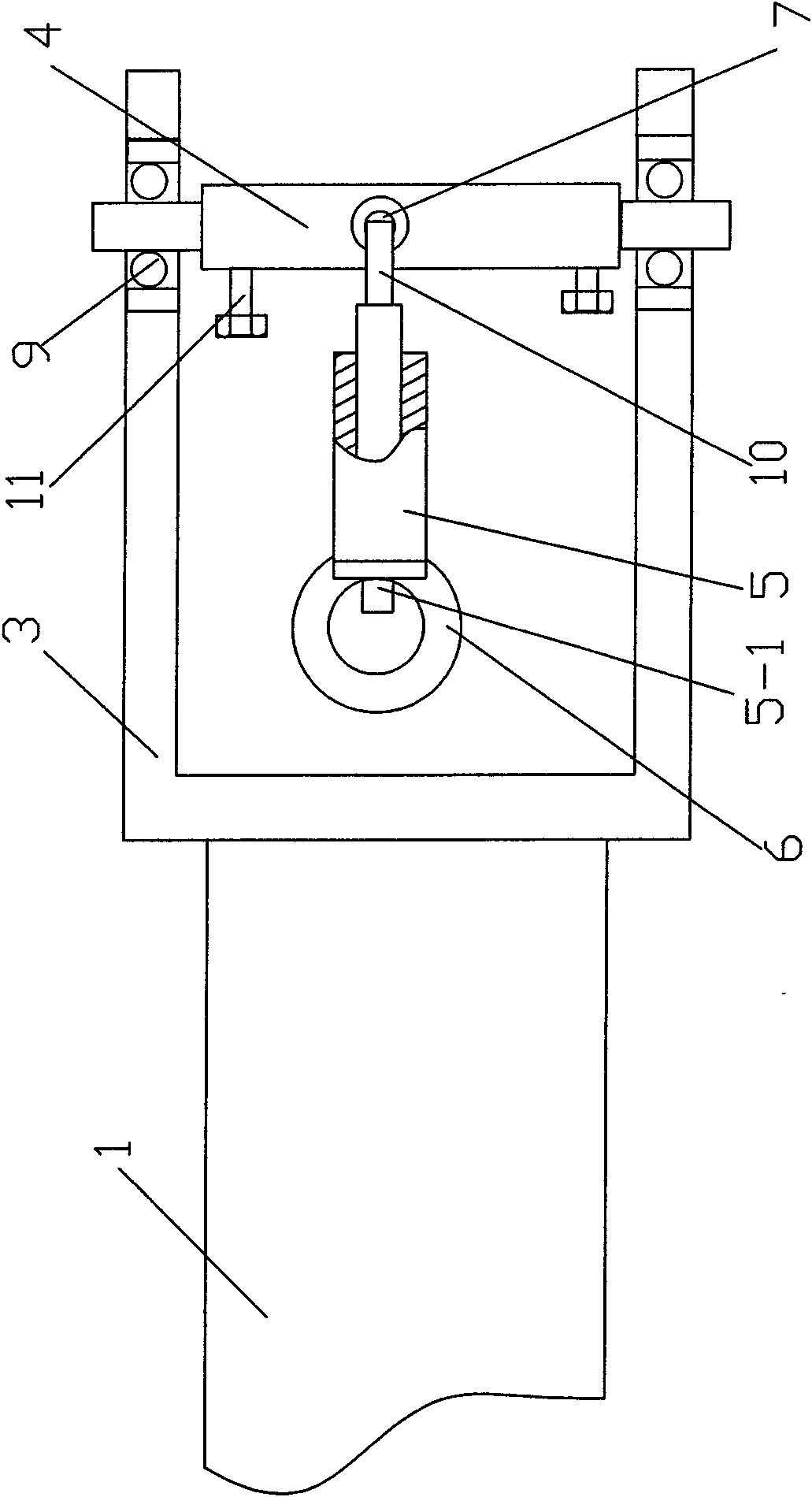

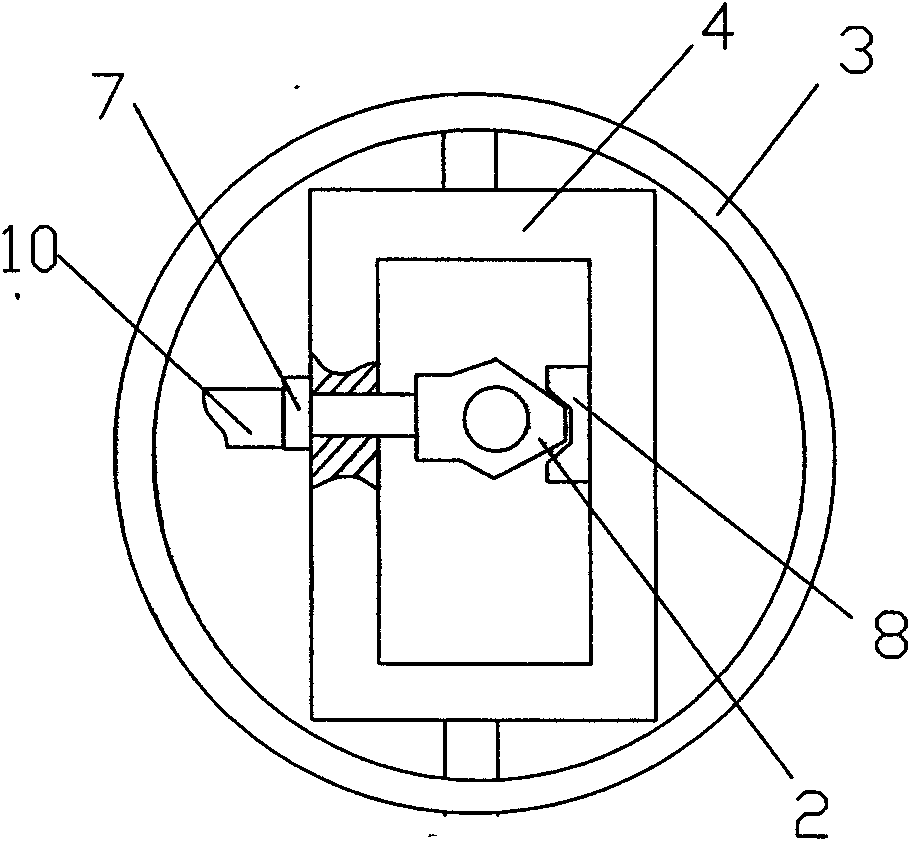

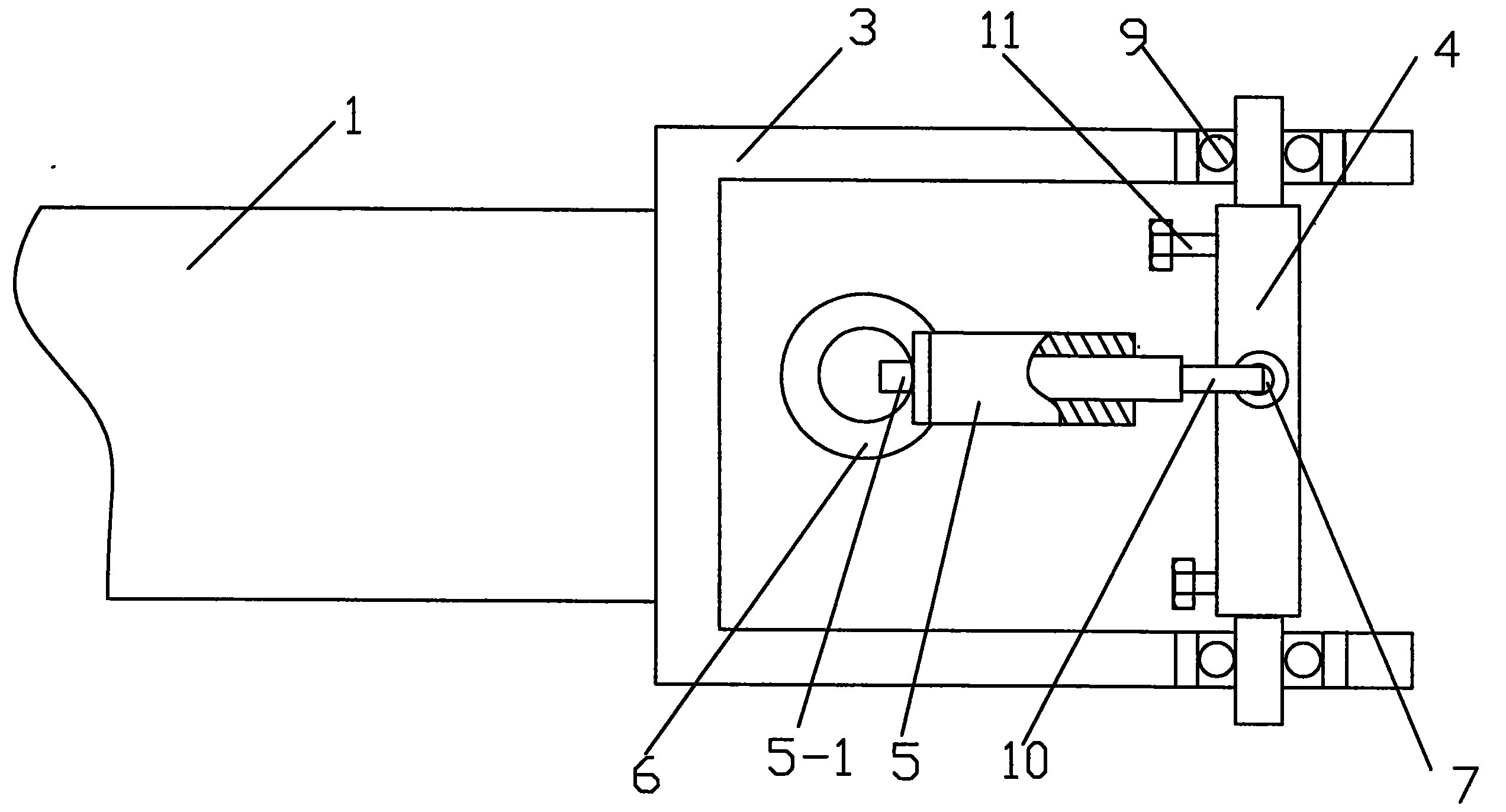

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] See the accompanying drawings for details, a special machine tool for processing the sealing seat of a gate valve body, including a lathe spindle 1 and a small carriage (not shown in the figure), the lathe spindle is equipped with an air-controlled fixture, and the air-controlled fixture is mainly composed of a housing 3 , swing frame 4, axial and radial cylinders 5, 6, pressure head 7 and V-shaped card seat 8, the housing is swingably connected to the middle part of the swing frame through a bearing 9, and the upper part of the swing frame slides A pressure head is connected, and the lower part of the frame corresponding to the pressure head is fixedly connected with a V-shaped card seat. The swing frame is connected to the axial cylinder body, and the shell is screwed to the spindle of the lathe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com