A Curve Simulation S-shaped Wedge Compensation Device

A compensation device and wedge block technology, applied in the field of curve simulation S-shaped wedge block compensation device, can solve problems such as affecting the working accuracy of hydraulic proportional valves, increasing machining accuracy errors, and mixing debris, etc., achieving broad market application prospects and adjusting Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

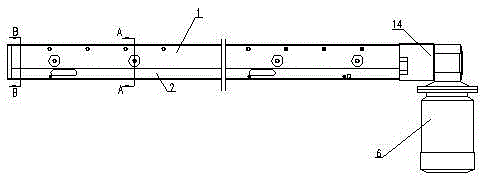

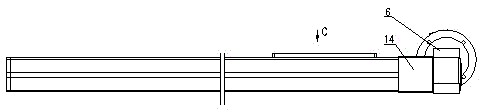

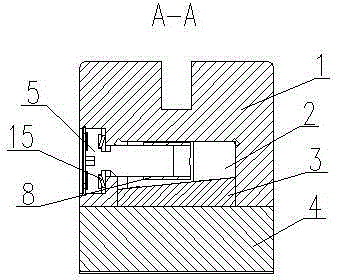

[0020] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention includes a compensation groove table 1, several S-shaped upper wedges 2, a whole S-shaped lower wedge 3, a bottom plate 4, an adjusting screw 5 and a transmission mechanism 6, and several S-shaped upper wedges 2 Fitting with a whole S-shaped lower wedge 3, it is built into the groove at the bottom of the compensating groove table 1, the bottom plate 4 is fixedly connected with the compensating groove table 1 through the screw 7, and the adjusting screw 5 passes through the compensating groove table 1 Connected with the nut 8 embedded in the S-shaped upper wedge 2, the transmission mechanism 6 includes a screw rod one 9, a screw rod two 10, a connecting block 11, a motor 12 and a reducer 13, and the motor 12 and the reducer 13 pass through the connecting block one 14 Fixedly installed at one end of the compensation groove table 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com