Novel polishing machine

A technology of polishing machine and polishing mechanism, which is applied in the field of polishing machines, can solve problems such as mechanical polishing and workpiece cannot be rotated, and achieve the effect of fast polishing speed, small footprint and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

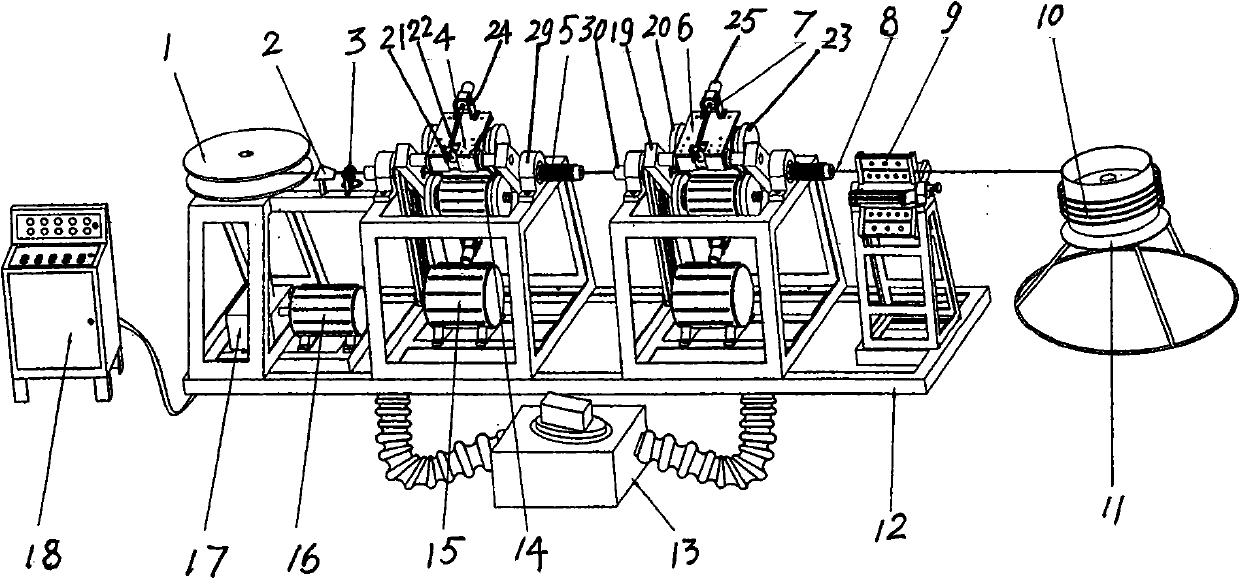

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

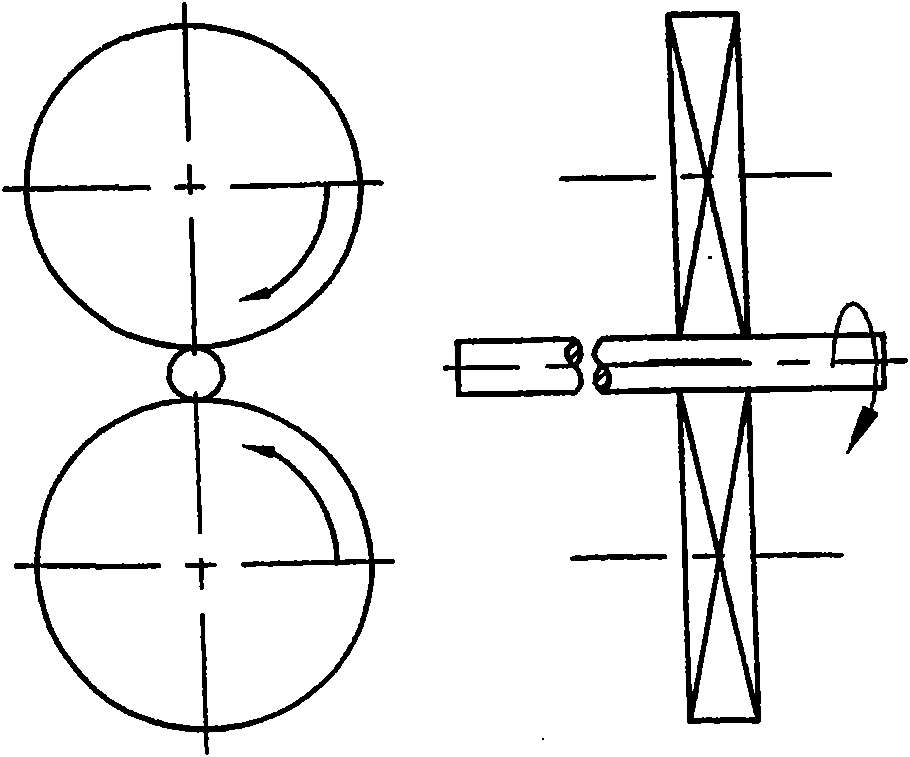

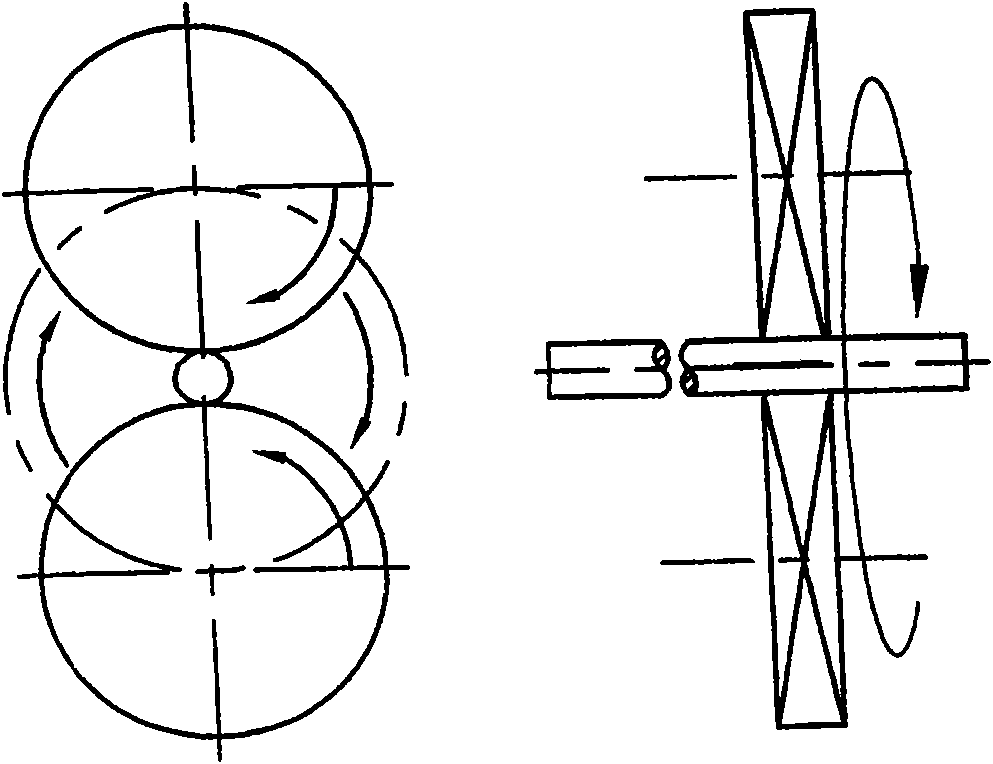

[0022] see Figure 3-Figure 8 , a novel polishing machine, which includes a base 12, a polishing mechanism, a power distribution / control device 18, a straightening device 9, a polishing mechanism and a receiving tray 1 are installed on the base 12, and the discharging rack 11 is placed on the base 12 Later, the polishing mechanism is composed of a main shaft 30, a main shaft motor 15, a pair of polishing motors 14, a pair of polishing wheels 20, and a rotating armature 5. The main shaft motor 15 is installed in the base 12, and the main shaft motor 15 drives the main shaft 30 to rotate, and the main shaft 30 In the middle is the rotating frame 19, the main shaft 30 drives the rotating frame 19 to rotate, the two ends of the main shaft 30 pass through the bearing housing 29, and the two bearing housings 29 are fixed on the base 12, and a pair of polishin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap