Processing technology of decorative holes of honeycomb board and fabricated honeycomb board with through holes

A processing technology and honeycomb board technology, which is applied in the direction of sheets/boards, building components, etc., can solve the problems affecting the overall strength of honeycomb boards, water seepage in perforated parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

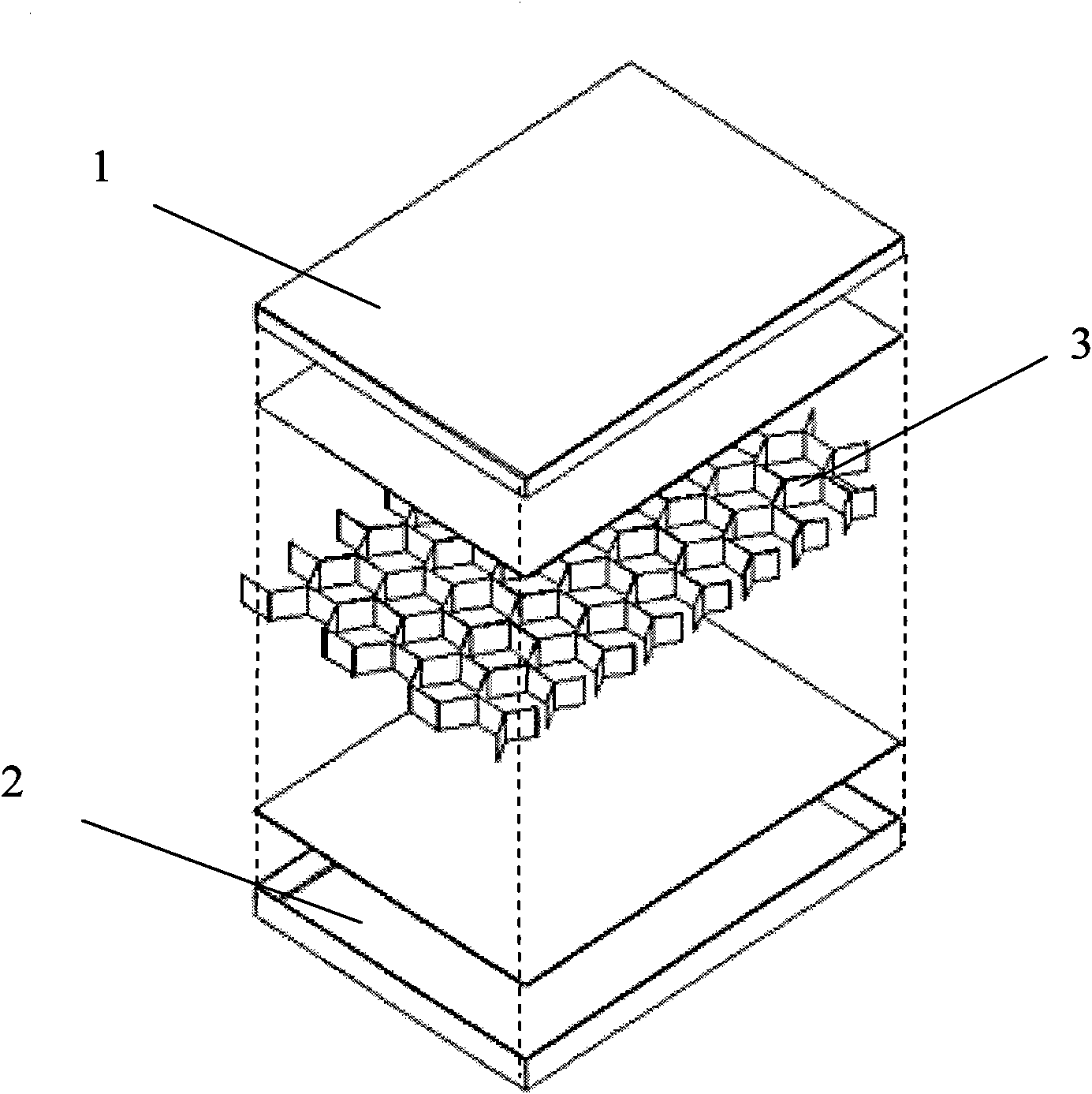

Embodiment 1

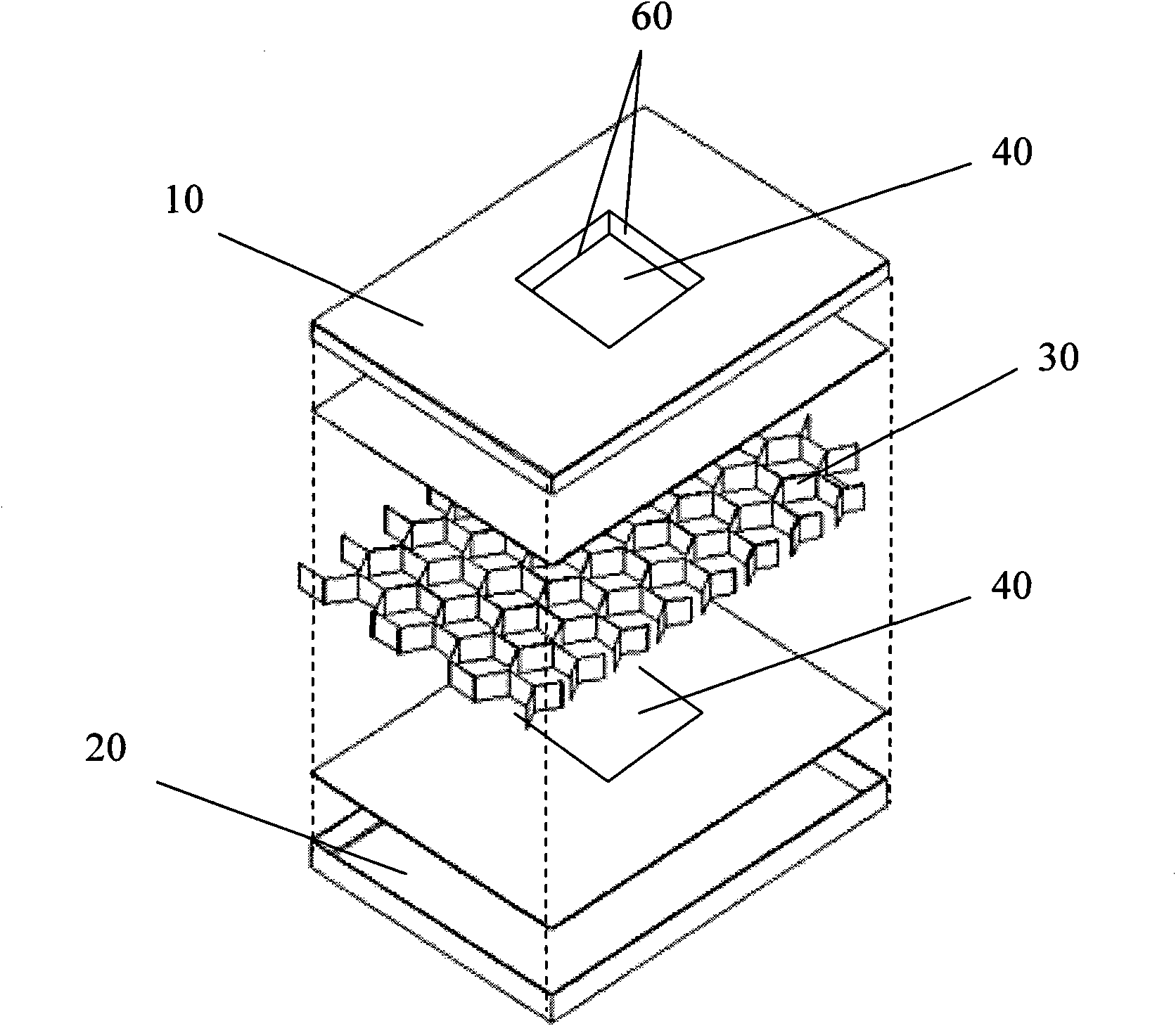

[0087] See figure 2 As shown, in this embodiment, the processing technology of rectangular, triangular, etc. through-holes 40 with right-angled sides is illustrated; the method uses a shroud 60 matching the shape and size of the inner sidewall of the through-hole 40 for sealing and shielding, and includes the following steps:

[0088] Step 1. Cut the hole;

[0089] Step 1.1 overall cutting;

[0090] The top plate 10, the honeycomb tubular support 30, and the bottom plate 20 in the fixed honeycomb panel that have been fixed by gluing are cut as a whole, so that a through hole 40 is formed inside the honeycomb panel, and the vertical section of the honeycomb tubular support 30 is consistent with the top plate 10, The cut surfaces of the bottom plate 20 are flush;

[0091] Step 1.2 limit compression;

[0092] Since the honeycomb-shaped tubular support 30 has a single point of yield, that is, the lateral compression of the honeycomb tubular support 30 can be achieved by applyi...

Embodiment 2

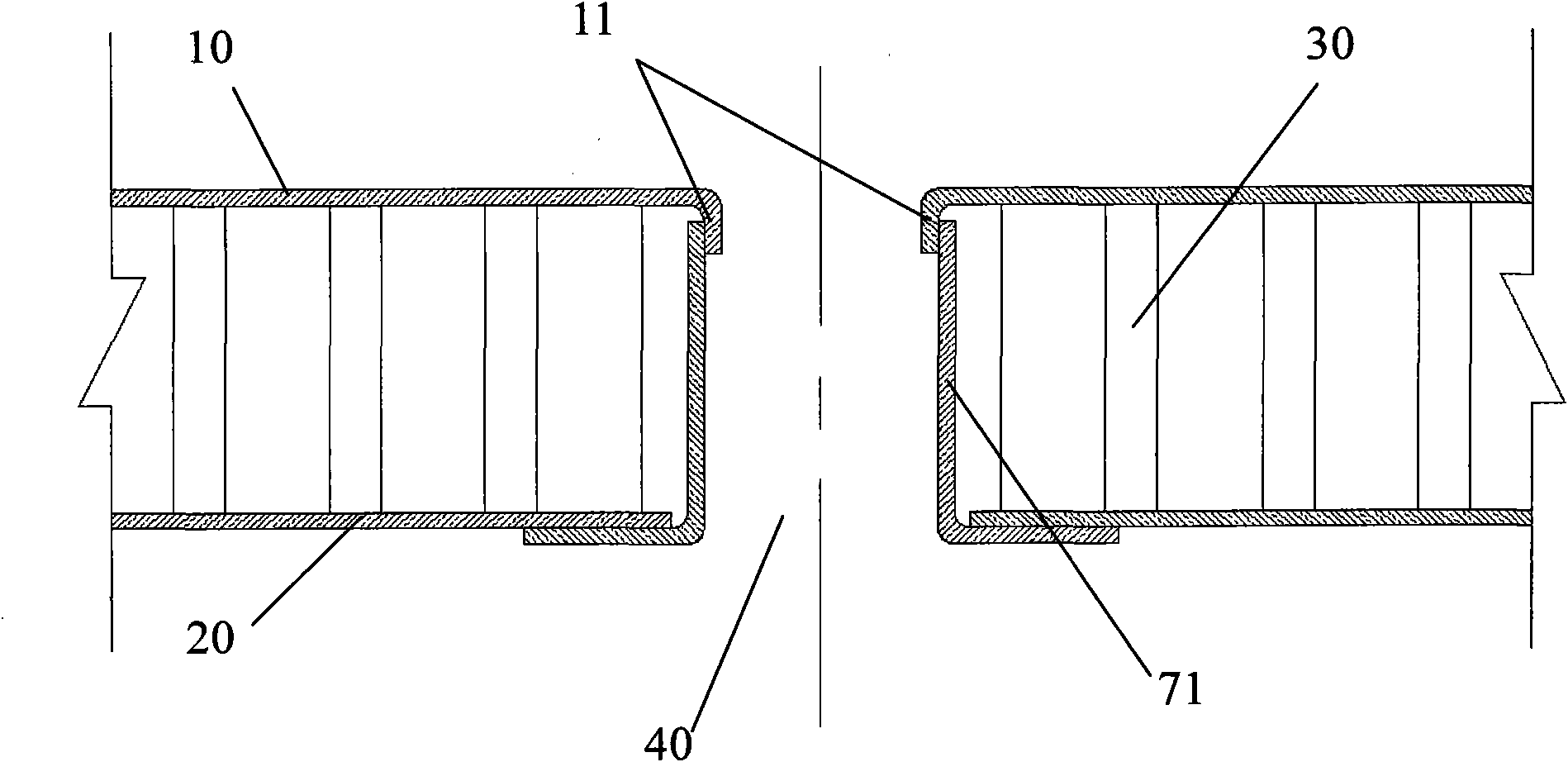

[0098] See image 3 As shown, the processing technology of the circular through hole 40 is illustrated in this embodiment; the method uses a single sleeve 71 for sealing and shielding, and the single sleeve 71 is L-shaped; the height of the single sleeve 71 is equal to the height of the honeycomb plate Matching; the outer diameter of the single sleeve 71 is the same as the diameter of the through hole 40 of the bottom plate 20, and the inner diameter is the same as the outer diameter of the top plate 10 socket 11.

[0099] The processing technology of the honeycomb plate to the circular through hole 40 comprises the following steps:

[0100] Step 1' cut the hole;

[0101] Step 1.1' overall punching;

[0102] Punch holes inside the glued and fixed honeycomb board so that the diameters of the through holes 40 on the top plate 10, the honeycomb tubular support 30 and the bottom plate 20 are consistent, and are all smaller than the set diameter of the through holes 40;

[0103]...

Embodiment 3

[0116] See Figure 4 As shown, another processing technology of the circular through hole 40 is illustrated in this embodiment; this method also uses an L-shaped single sleeve 71 for sealing and shielding, and the structure of the single sleeve 71 is similar to that in Embodiment 2. The difference is that the processing technology of the honeycomb plate to the circular through hole 40 includes the following steps:

[0117] Step 1' cut the hole;

[0118] Step 1.1' overall punching;

[0119] Punch holes inside the glued and fixed honeycomb board so that the diameters of the through holes 40 on the top plate 10, the honeycomb tubular support 30 and the bottom plate 20 are consistent, and are all smaller than the set diameter of the through holes 40;

[0120] Step 1.2' reaming of base plate 20;

[0121] Taking the through hole 40 of the top plate 10 as a benchmark, the through hole 40 of the base plate 20 is reamed, so that the diameter of the through hole 40 of the base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com