Mining height instrument for continuous miner

A technology of shearer and height meter, which is applied to instruments, cutting machinery, earth-moving drilling, etc., can solve hidden safety hazards, it is difficult to ensure that the roof and floor are level, and the shearer driver cannot clearly see the exact position of the drum, etc. problems, to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

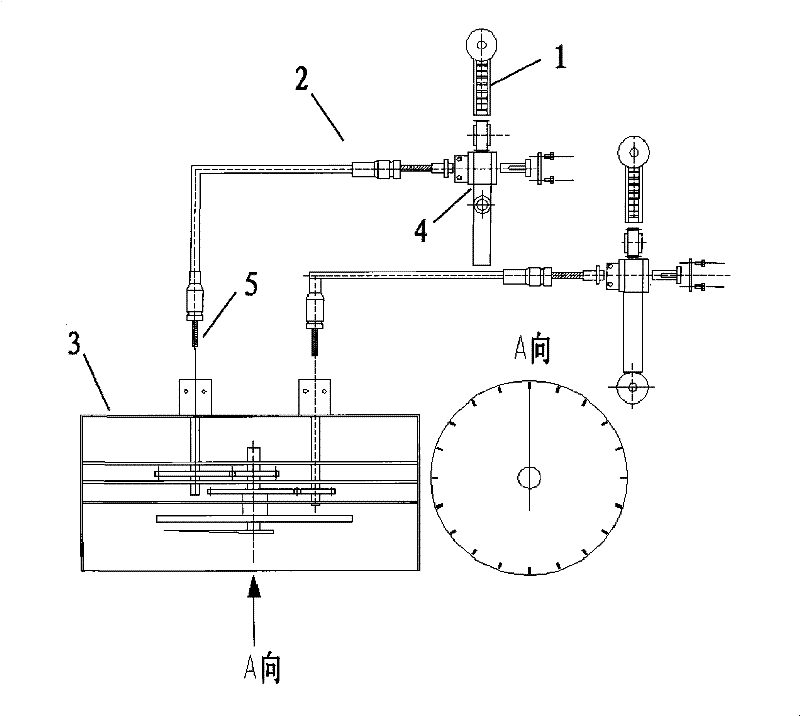

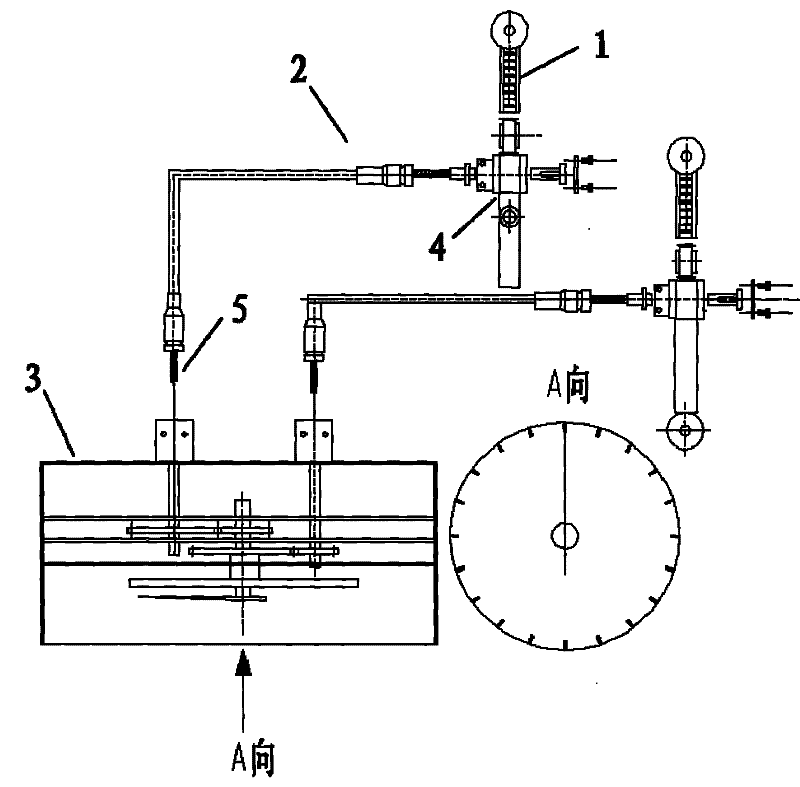

[0014] figure 1 It is a structural schematic diagram of a mining height instrument used for a continuous coal mining machine in an embodiment of the present invention. As shown in the figure, it includes a rack 1, a transmission device 2, and an indicating device 3, wherein the rack is used to be connected to the cutting arm of the continuous coal mining machine; one end of the transmission device is engaged with the rack, and the other end Connect with pointing device. figure 1 Also shows a schematic diagram of the pointing device 3 viewed along the A direction.

[0015] The rack 1 is installed on the cutting arm of the continuous coal mining machine, and the number of teeth and the modulus of the rack 1 are matched with the number of teeth and the modulus of the meshed gears in the transmission device 2 .

[0016] The transmission device 2 can be implemented in various ways according to the actual application situation. In this preferred embodiment, it includes a gear 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com