Battery anti-explosion system

An explosion-proof system and battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as battery explosion, battery internal pressure drop, battery short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

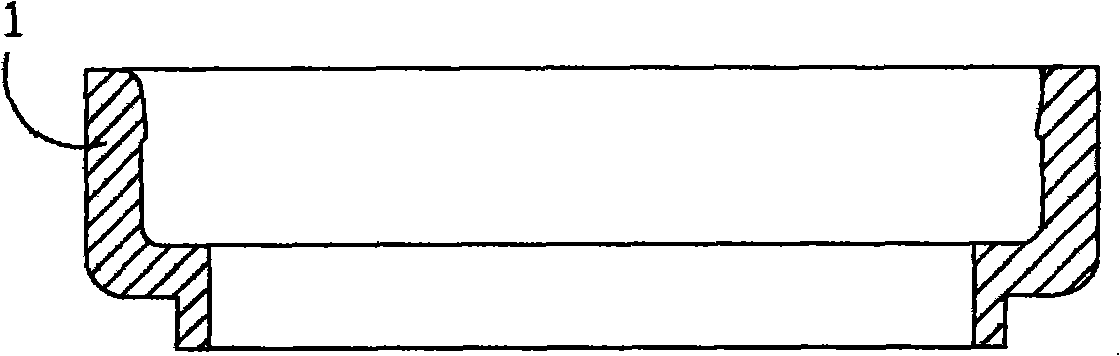

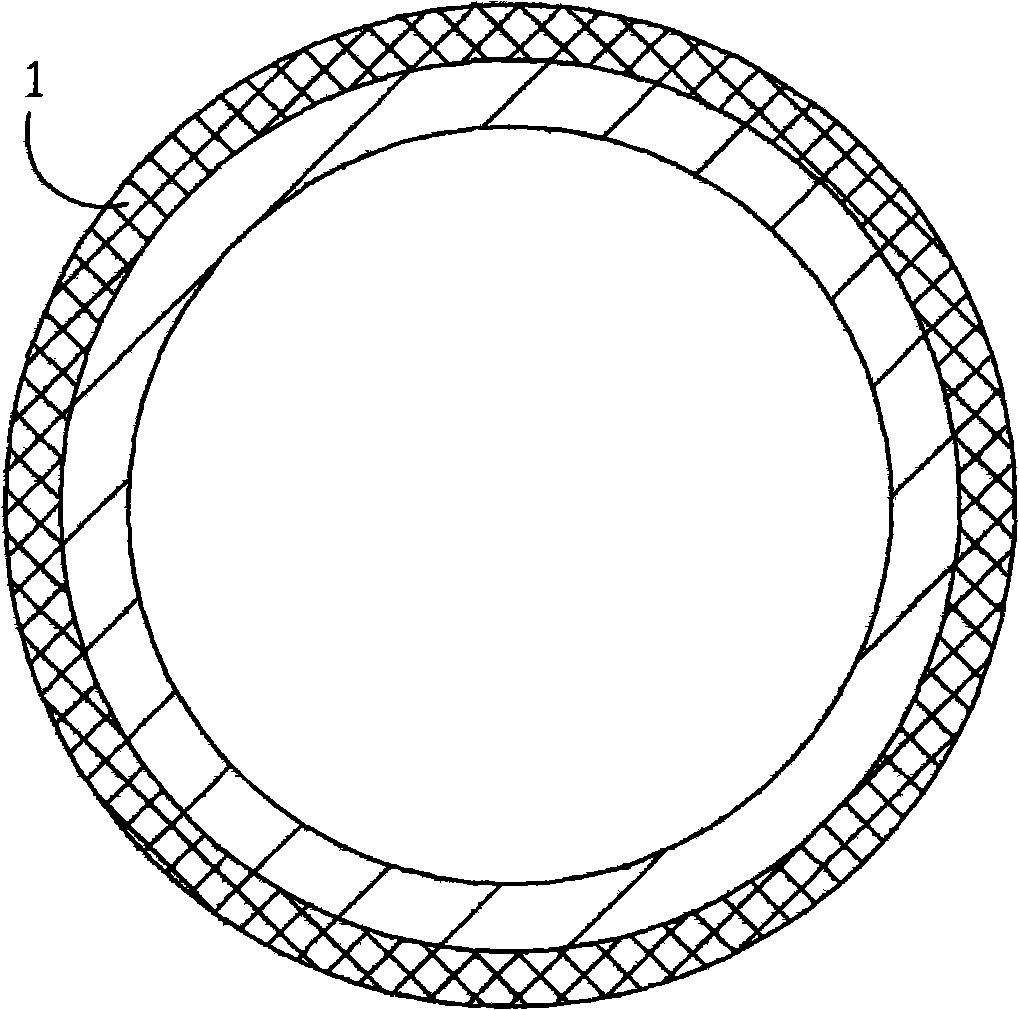

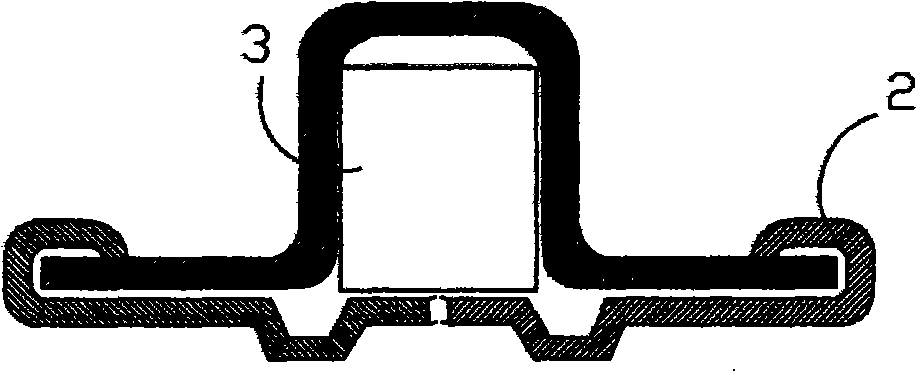

[0017] Such as Figure 5 to Figure 9 A battery explosion-proof system shown mainly includes a sealing ring 4, a cap 5 and an anti-explosion ball 6 arranged in the cap 5. The present invention mainly aims at optimizing the design of the sealing ring 4 material and the cap 5. In the existing various The polypropylene material is selected to be made into the sealing ring 4 among the plastic materials. The polypropylene material will soften or partially melt under high temperature conditions of 80°C-100°C, causing a gap between the battery steel shell and the cap to release the gas inside the battery, reduce the internal pressure of the battery, and prevent the battery from exploding. In the design of the cap 5, rubber that can fail under high temperature conditions is selected as the material of the explosion-proof ball 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com