Fastening method suitable for part with hole and device thereof

A technology for fastening devices and parts, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve problems such as low efficiency, cumbersome clamping and disassembly of parts, and inability to meet the requirements of large-scale production and processing, and achieve the effect of implementation. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

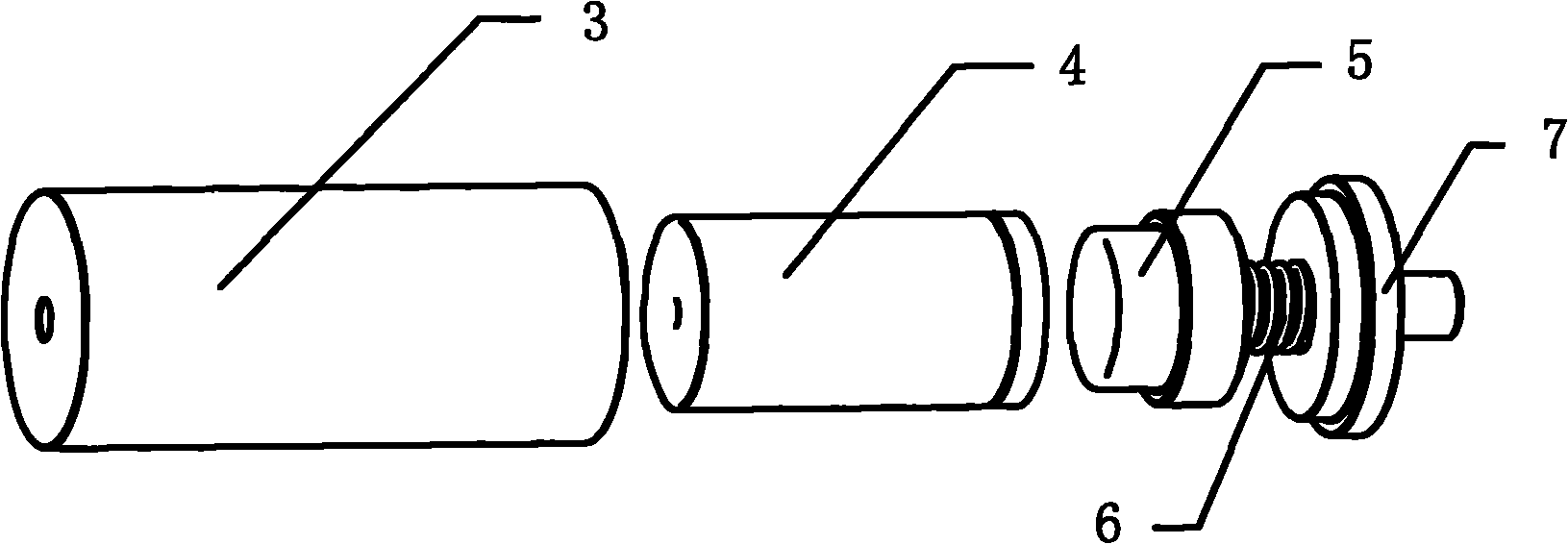

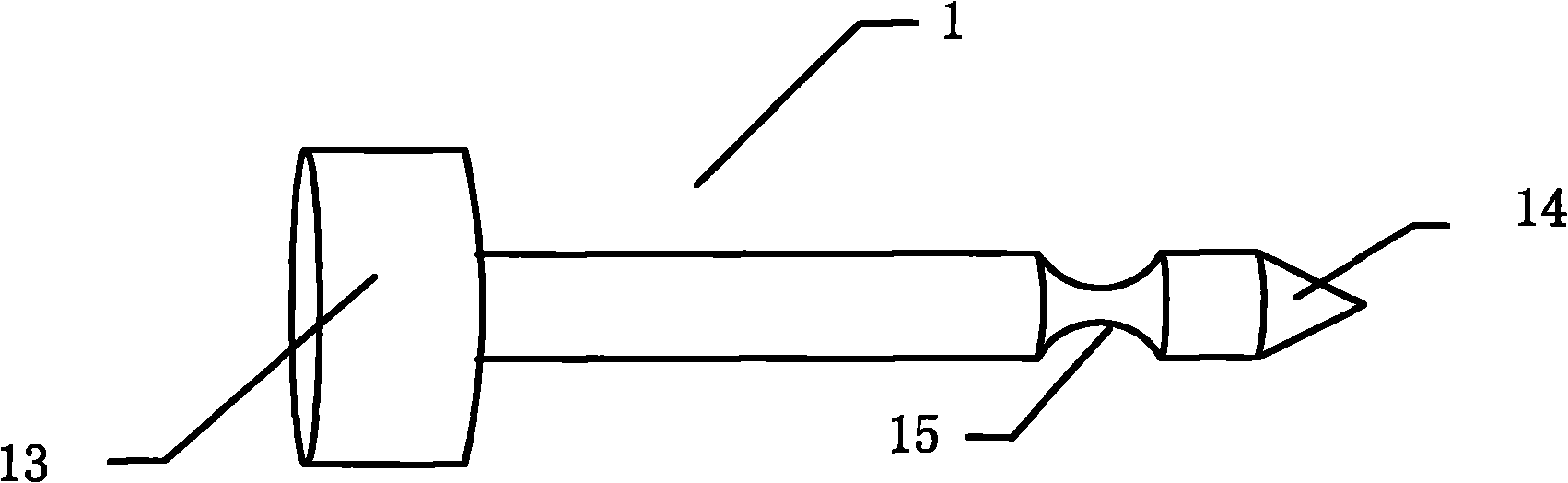

[0037] Such as Figure 1-6 The shown fastening device for parts with holes is special in that it includes a tension pin 1 and a quick tension sleeve 2, and the quick tension sleeve 2 includes a housing 3, a self-locking unit 4, and a magnet pull rod 5. The outer spring 6 and the outer end cover 7, the bottom of the self-locking unit 4 is provided with a magnet pull rod 5, the bottom end of the magnet pull rod 5 is connected with the outer end cover 7 through the outer spring 6, and the outer shell 3 is sleeved on the self-locking unit 4 , Magnet pull rod 5, outer spring 6 and outer end cover 7, the tension pin 1 is inserted into the quick tension sleeve 2 and locked by the self-locking unit 4 during use.

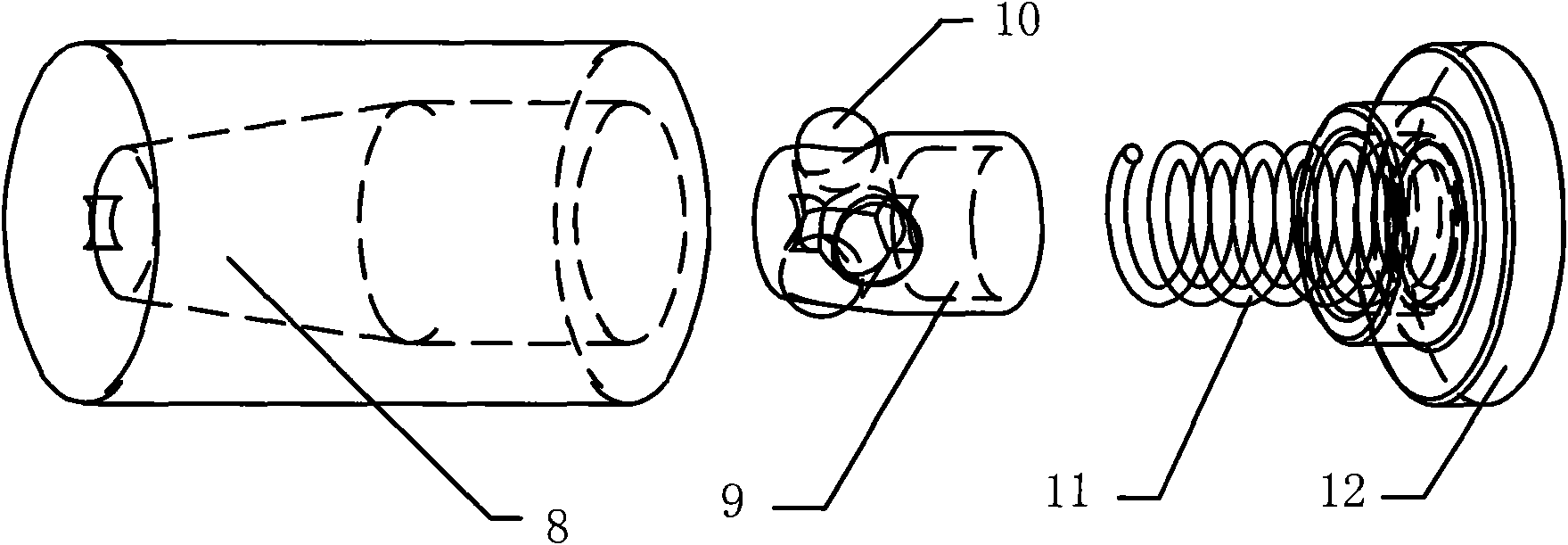

[0038] Looking further, the self-locking unit 4 includes an outer locking sleeve 8, an inner locking sleeve 9, a steel ball assembly, an inner spring 11, and an inner end cover 12. The outer locking sleeve 8 is provided with an accommodation space, and the inner locking slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com