Novel cooling structure for tangent type rotator of internal mixer

A cooling structure and mixer technology, applied in the field of tangential rotors, can solve the problems of slow cooling medium flow rate, large inner cavity water capacity, poor cooling effect, etc., to improve strength and rigidity, and increase the bending section coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

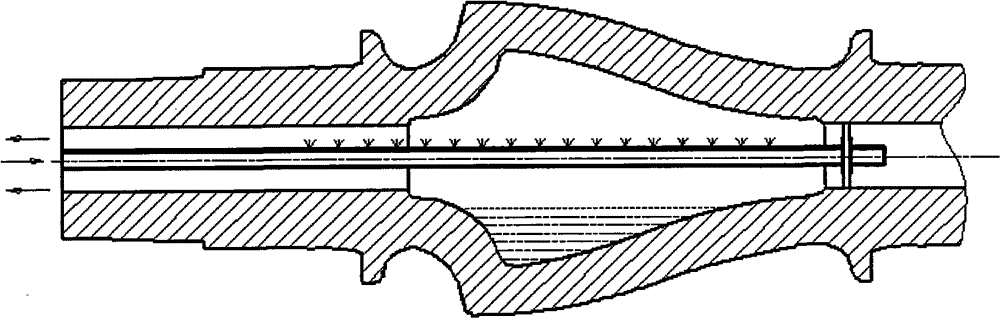

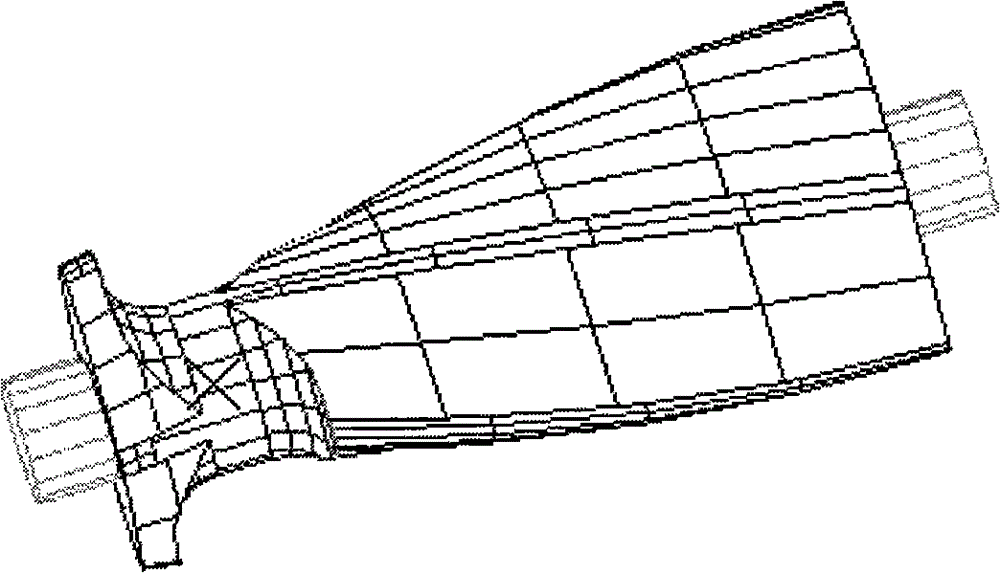

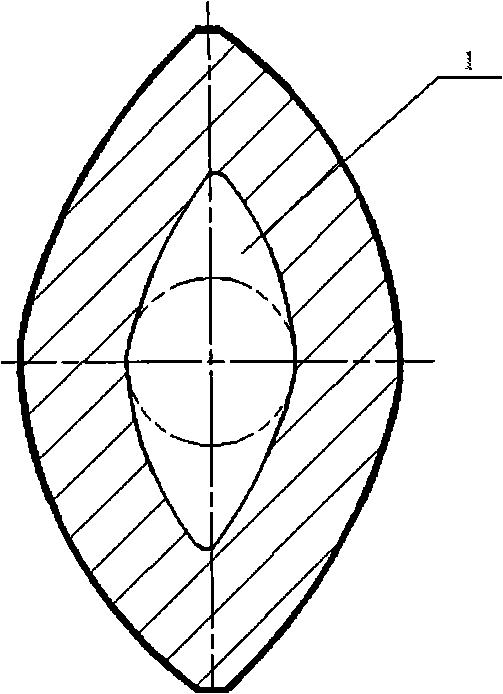

[0022] The cooling water flow direction of the new cooling structure of the tangential rotor of the internal mixer, the cooling water flow direction is as follows Figure 7 As shown, the cooling water passes through the central cavity Figure 13 The two long holes in the F-F section enter one cavity in the long edge of the rotor, then flow to the other cavity, and then pass through Figure 8 The A-A cross-section has two long holes in the inner cavity of the long edge and then enters the gap between the central cavity and the casing and flows out.

[0023] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto, and any person familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof shall fall within the protection scope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com