Composite rotating disk liquid film reactor and method for processing organic wastewater

A technology of liquid film reactor and organic wastewater, applied in the direction of light water/sewage treatment, etc., can solve the problems of complex structure of double turntable, easy corrosion of stainless steel, no contribution to wastewater treatment, etc., to overcome easy corrosion by acid solution, simplify Reaction device, effect of improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Treatment of Dye Wastewater by TiO2 / Stainless Steel / Cu Composite Rotary Disk Liquid Film Reactor

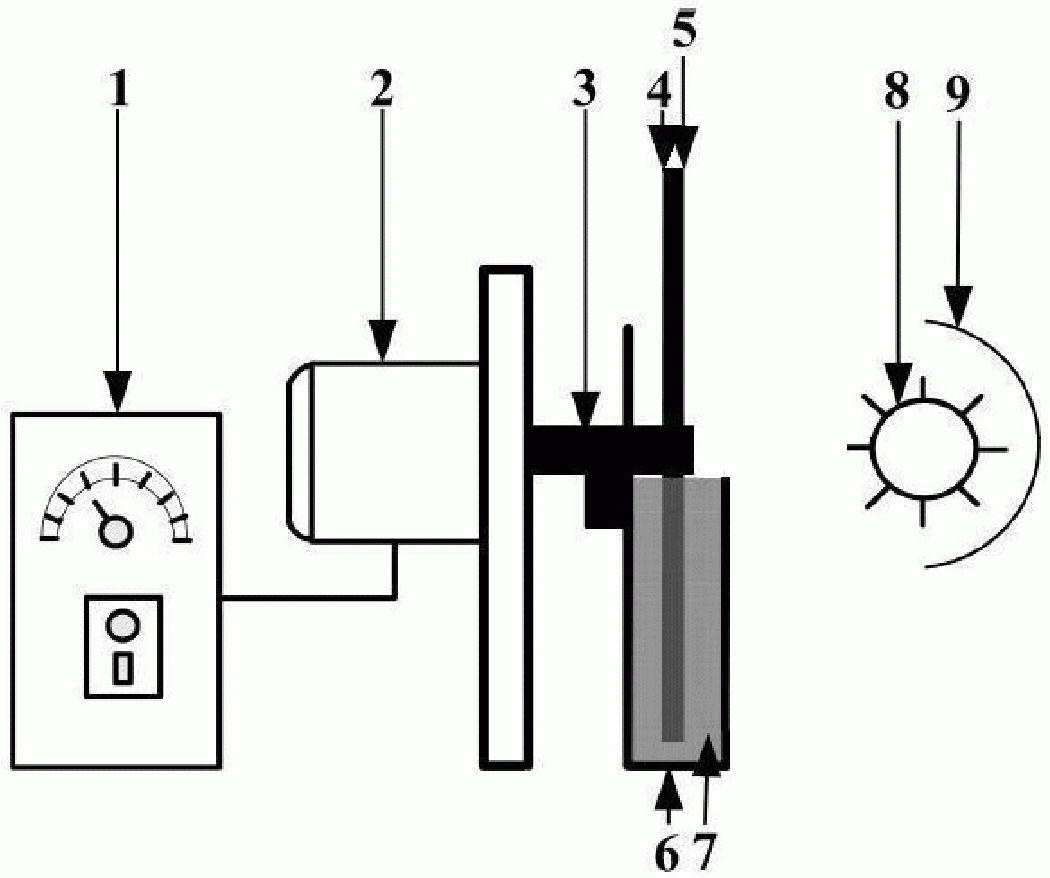

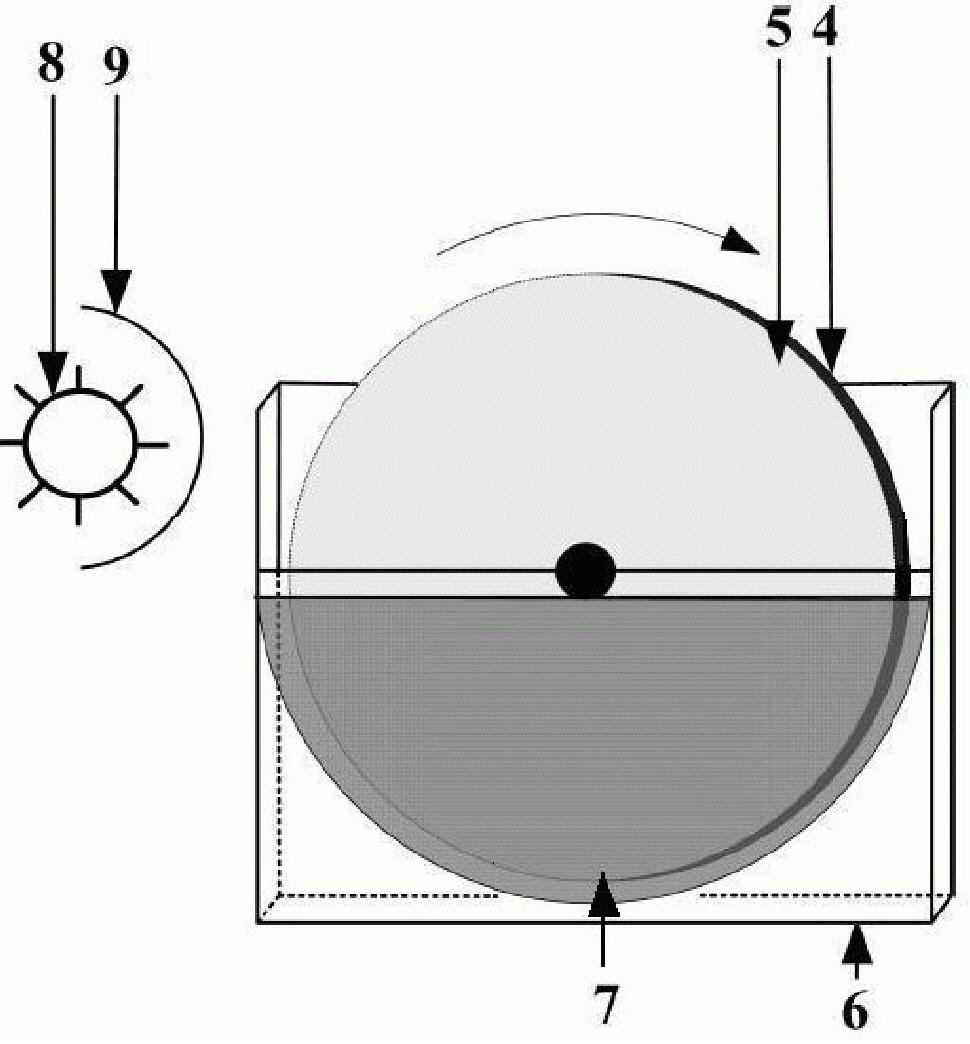

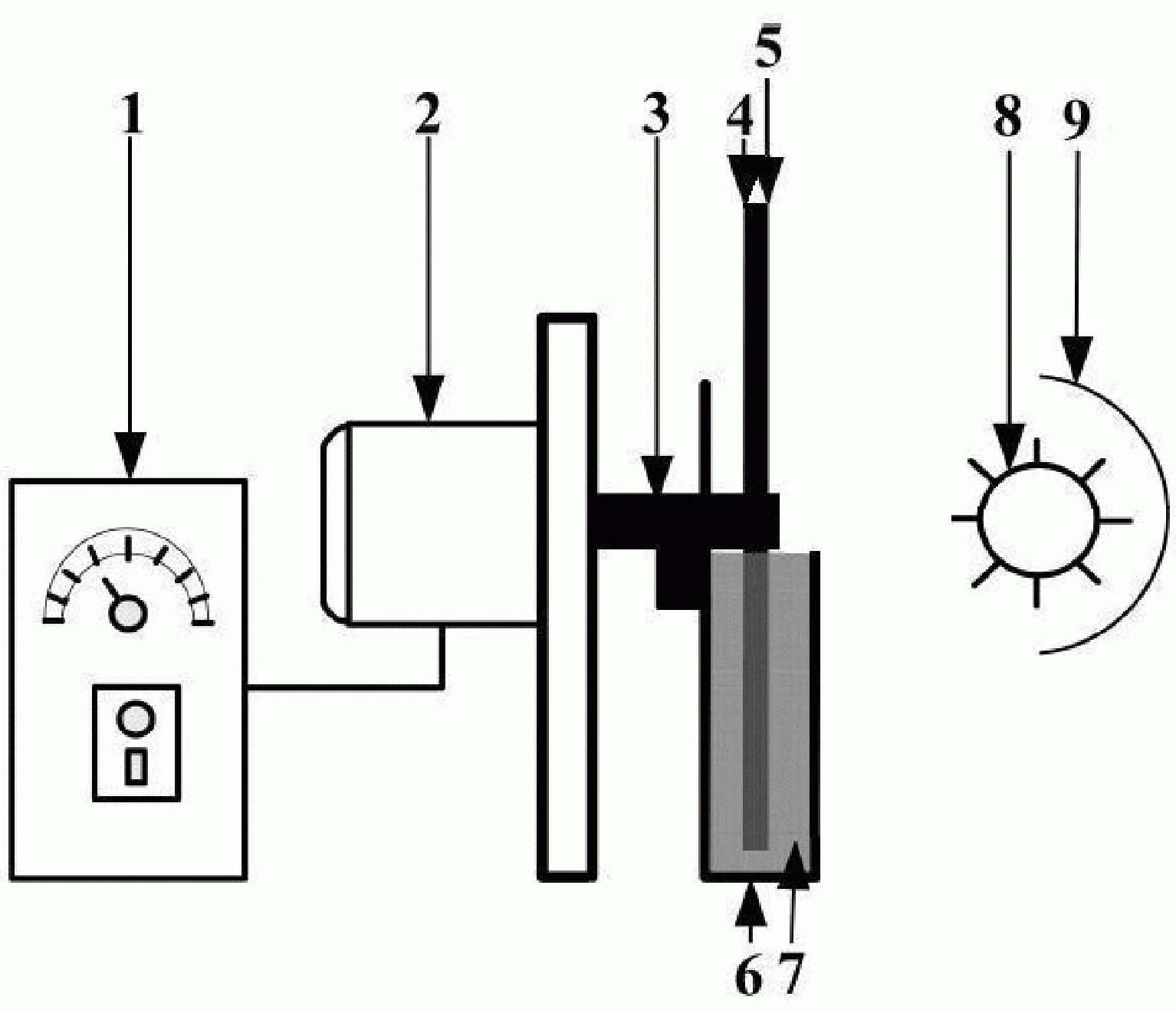

[0028] Such as figure 1 and figure 2 As shown, the treatment object is 50mg / L reactive brilliant red X-3B (pH 2.50, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater, the volume of wastewater is 50mL.

[0029] Using stainless steel disks as substrates, TiO 2 The photocatalyst is loaded on the substrate, and Cu is electroplated on the other side of the substrate by EDTA method to form TiO 2 / Stainless steel / Cu composite turntable, the composite turntable is fixed on the rotating shaft and connected with the motor.

[0030] The composite turntable is placed in the semi-arc reaction tank, the rotating shaft of the composite turntable is at the water surface of the wastewater, so that the lower half of the composite turntable is submerged in the wastewater.

[0031] Start the motor, and control the rotation speed of the composite turntable to 90 rpm through the governor, so...

Embodiment 2

[0038] TiO 2 / Ti / Cu Composite Rotary Disk Liquid Film Reactor for Dye Wastewater Treatment

[0039] The treatment object is 50mg / L Reactive Brilliant Red X-3B (pH 2.50, 1.0 g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume is 50mL.

[0040] Step is with embodiment 1, and wherein metal substrate is Ti substrate, and the waste water treatment time is 1 hour, asks decolorization rate (%), and result is as follows:

[0041] time (min)

[0042] It can be seen that Ti can also be used as the metal substrate of this reactor, and satisfactory results can be obtained after 1 hour of treatment.

Embodiment 3

[0044] TiO 2 / Stainless steel / Cu composite turntable liquid film reactor for treating dye wastewater with different pH values

[0045] The treatment object is 50mg / L Reactive Brilliant Red X-3B (1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume is 50mL.

[0046] Step is with embodiment 1, asks decolorization rate (%), and result is as follows:

[0047] The pH value of Reactive Brilliant Red X-3B

[0048] It can be seen that the TiO2 / stainless steel / Cu composite rotating disk liquid membrane reactor has the best effect in treating dye wastewater under the acidic condition of pH 2.50. In the structure of the composite turntable, the cathode Cu can block the direct contact between the stainless steel substrate and the solution, preventing it from being corroded by the acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com