Reflective cup set for light emitting diode (LED) lamp

A technology of LED lamps and LED lamps, applied in the field of reflector cups, can solve the problems of unsuitability for lighting systems, large divergence angles, and low energy of LED lights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

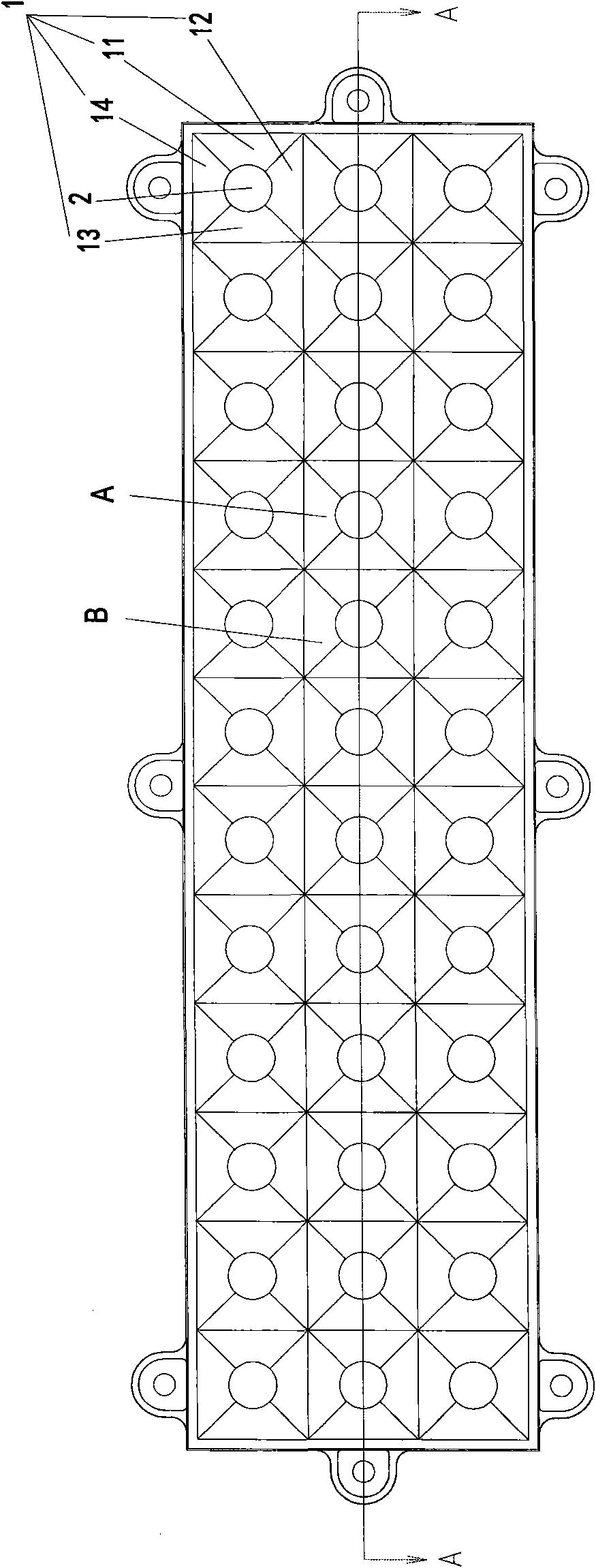

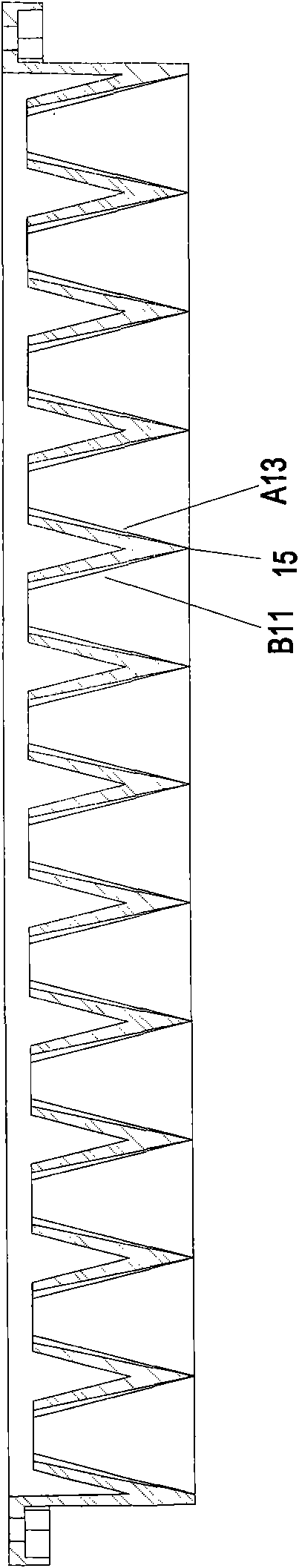

[0017] See figure 1 , figure 2 As shown, the reflective cup set of the LED lamp of the present invention is composed of thirty-six identical reflective cups. The thirty-six reflective cups are located in the same plane and are connected in series with each other. Prismatic, with four reflective surfaces, namely reflective surface 11, reflective surface 12, reflective surface 13, and reflective surface 14. The curvature of these four reflective surfaces is the same, and the curvature is determined according to the target plane and the position of the LED light. , the design curvature of each reflective cup ensures that the reflected light can reach the target plane, and the direct irradiation and reflected light are superimposed to make the target plane illuminate evenly; the LED light 2 is located in the center of the reflective cup cover body 1, and there is a The external reflective surface is connected, see figure 2 As shown, the reflective cup A is adjacent to the refl...

Embodiment 2

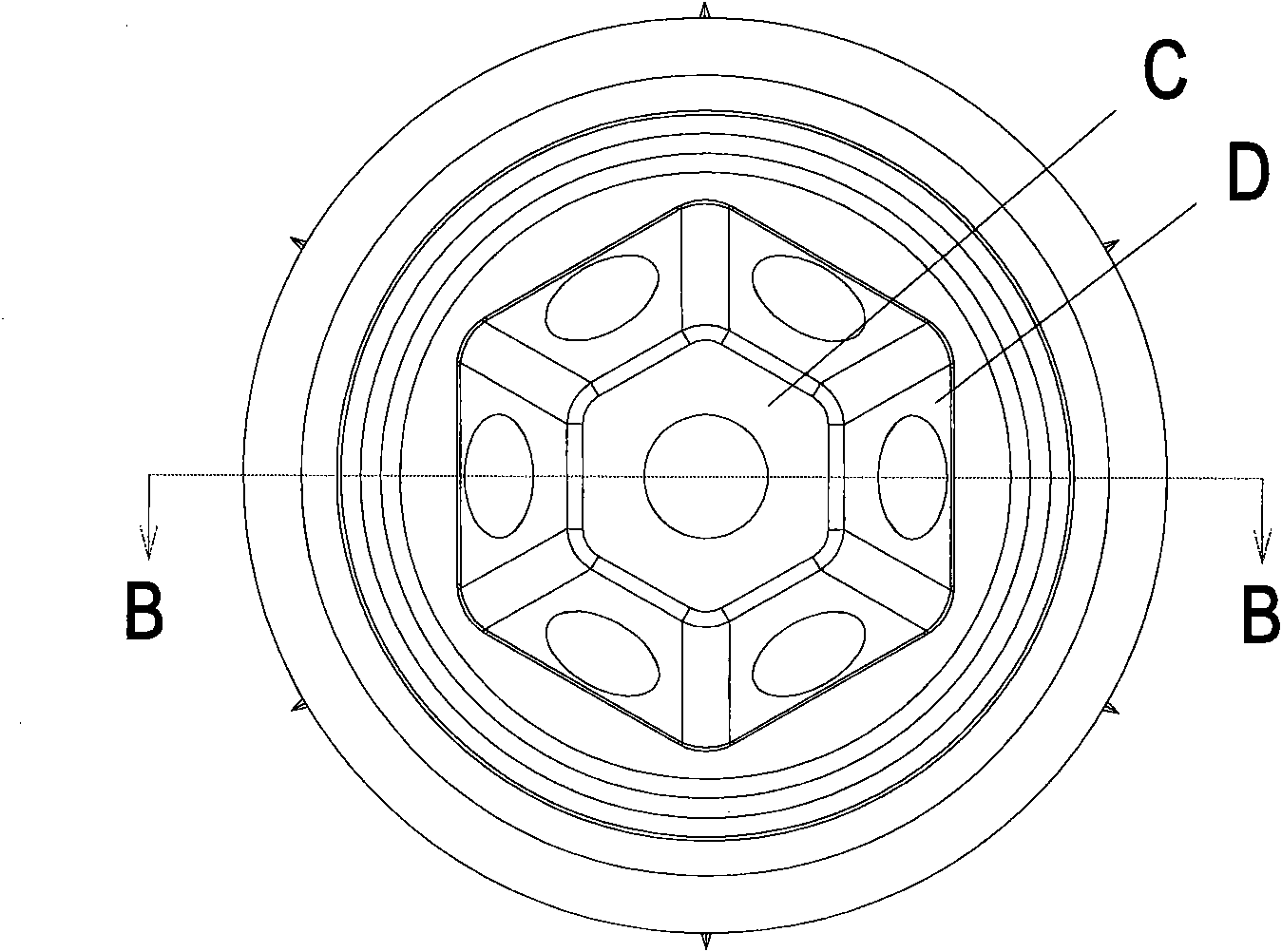

[0019] See image 3 , Figure 4 As shown, the reflecting cups of this reflecting cup set are not all in the same plane, and the shapes of the reflecting cups are also different. The curvature of each reflective surface in a reflective cup is also different. The shape and curvature of each reflective surface should be based on the actual situation. The design is determined, as shown in the figure, the reflective cup C is adjacent to the reflective cup D, and its reflective surface C11 is adjacent to the reflective surface D13. It is a straight edge. All the adjacent reflective surfaces of two adjacent reflective cups are close together to form a linear sharp edge to form a seamless whole. Since reflective cup C and reflective cup D are not in the same plane, reflective cup C and reflective cup D are not in the same plane. The shape of the reflecting cup D is different, such as Figure 4 As shown, the curved surfaces of the reflective surface C11 and the reflective surface D1...

Embodiment 3

[0021] See Figure 5 , Image 6 As shown, it is composed of seven reflective cups. The seven reflective cups are located in the same plane. There are six reflective cup covers in the form of irregular quadrangular prisms, and one reflective cup cover E is in the shape of a regular hexagonal prism. The reflective cup E and The reflective cup F is adjacent, and its reflective surface E11 is adjacent to the reflective surface F13. The two reflective surfaces are close together to form a whole, and the end 17 thus formed is a straight-line sharp edge. All the adjacent reflective surfaces of two adjacent reflective cups are connected together to form a linear sharp edge so as to form a seamless whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com