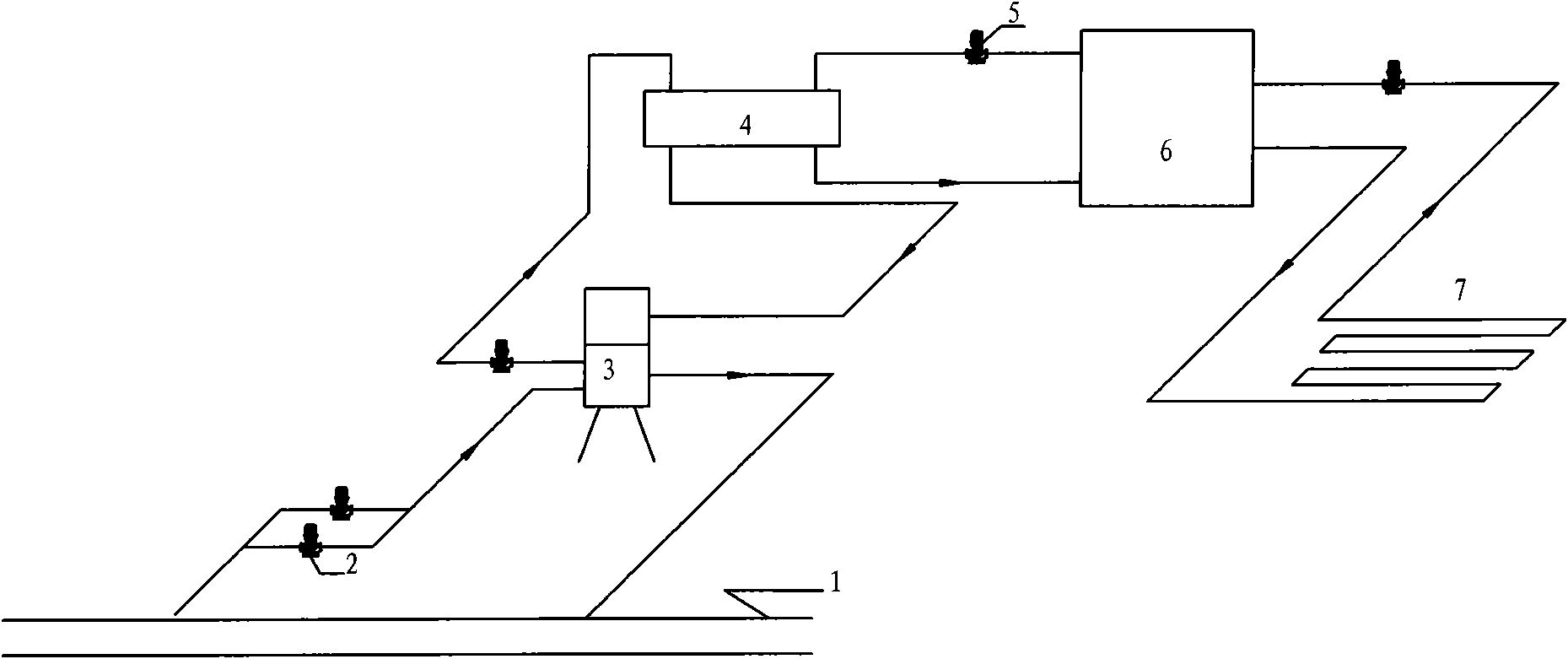

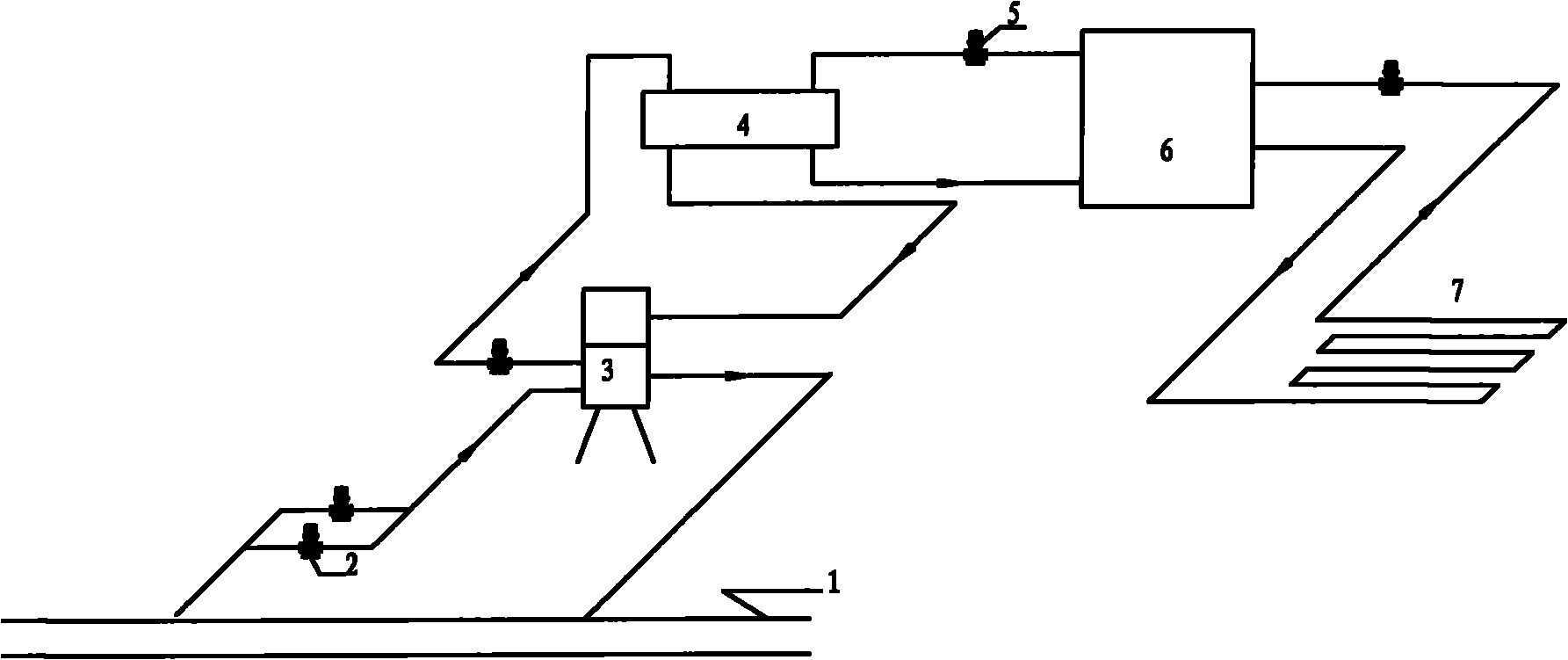

Untreated sewage source heat pump system

A sewage source heat pump and sewage technology, applied in heat recovery systems, air conditioning systems, household heating, etc., can solve the problems of shell and tube heat exchangers that are easy to block and not suitable for cleaning, so as to improve operational stability, easy cleaning, and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The system of the present invention mainly includes a sewage submersible pump 2, a sewage automatic decontamination machine 3, a detachable spiral plate heat exchanger 4, a heat exchange circulation pump 5, a water source heat pump unit 6, and an air conditioner terminal 7. The pipeline is pumped to the automatic sewage decontamination machine 3 through the sewage submersible pump 2, and enters the three filter chambers in the cylindrical filter through the sewage outlet set in the sewage water separator. The filter screen is isolated into the filter chamber, and the filtered sewage enters the water supply chamber between the shell and the cylindrical filter screen, and then the water supply port on the shell provides a low-temperature heat source to the detachable spiral plate heat exchanger, and the sewage is detachable. After heat exchange, the type spiral plate heat exchanger returns to the backwash chamber between the shell and the cylindrical filter through the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com