Full-plastic pressure-bearing dual-bucket horizontal type dual-circulation liner

A dual-circulation, liner technology, used in solar thermal power generation, fluid heaters, heating devices, etc., can solve the problems of short life and high price of enamel liner, and achieve the effect of saving metal raw materials, long life and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

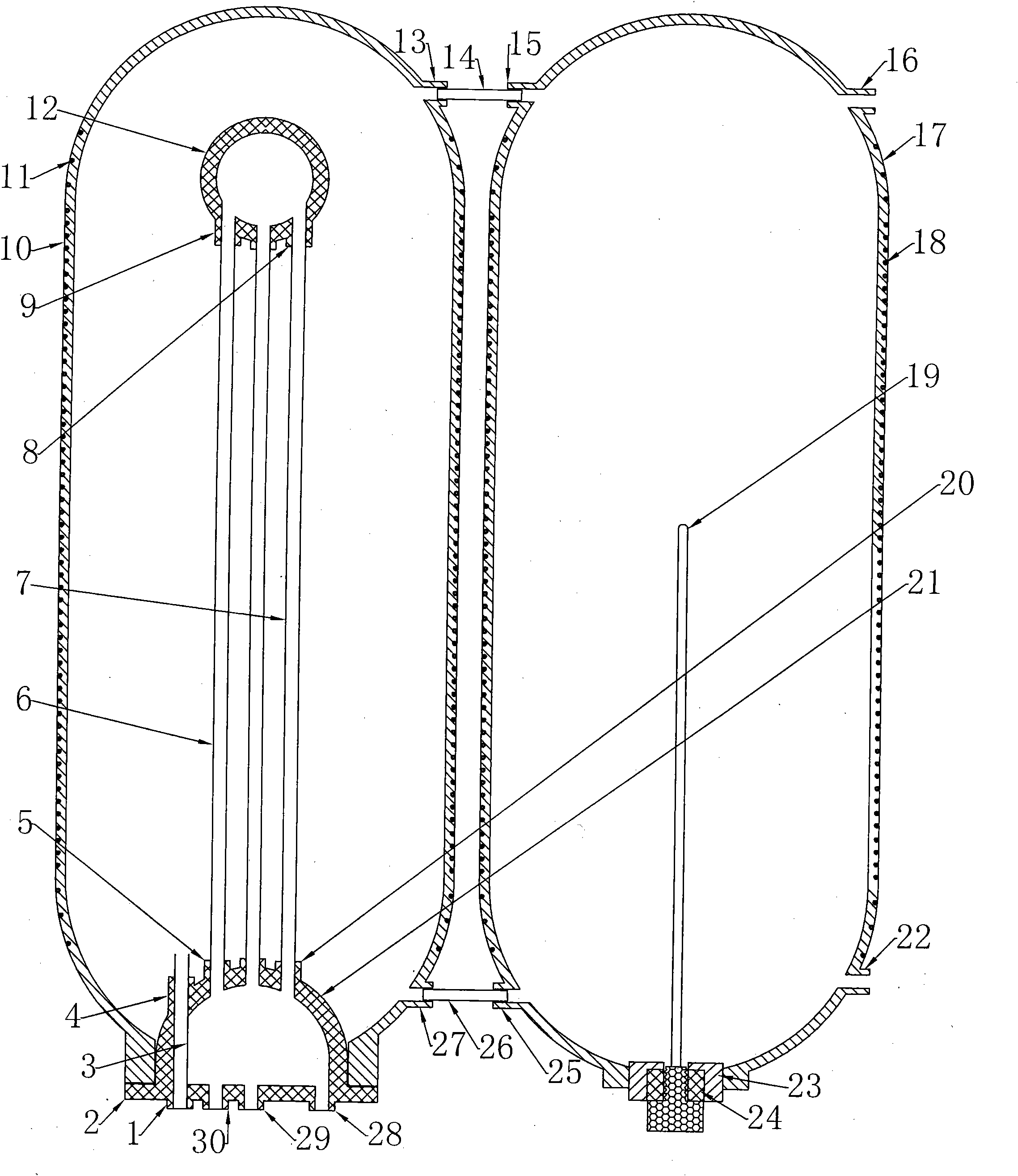

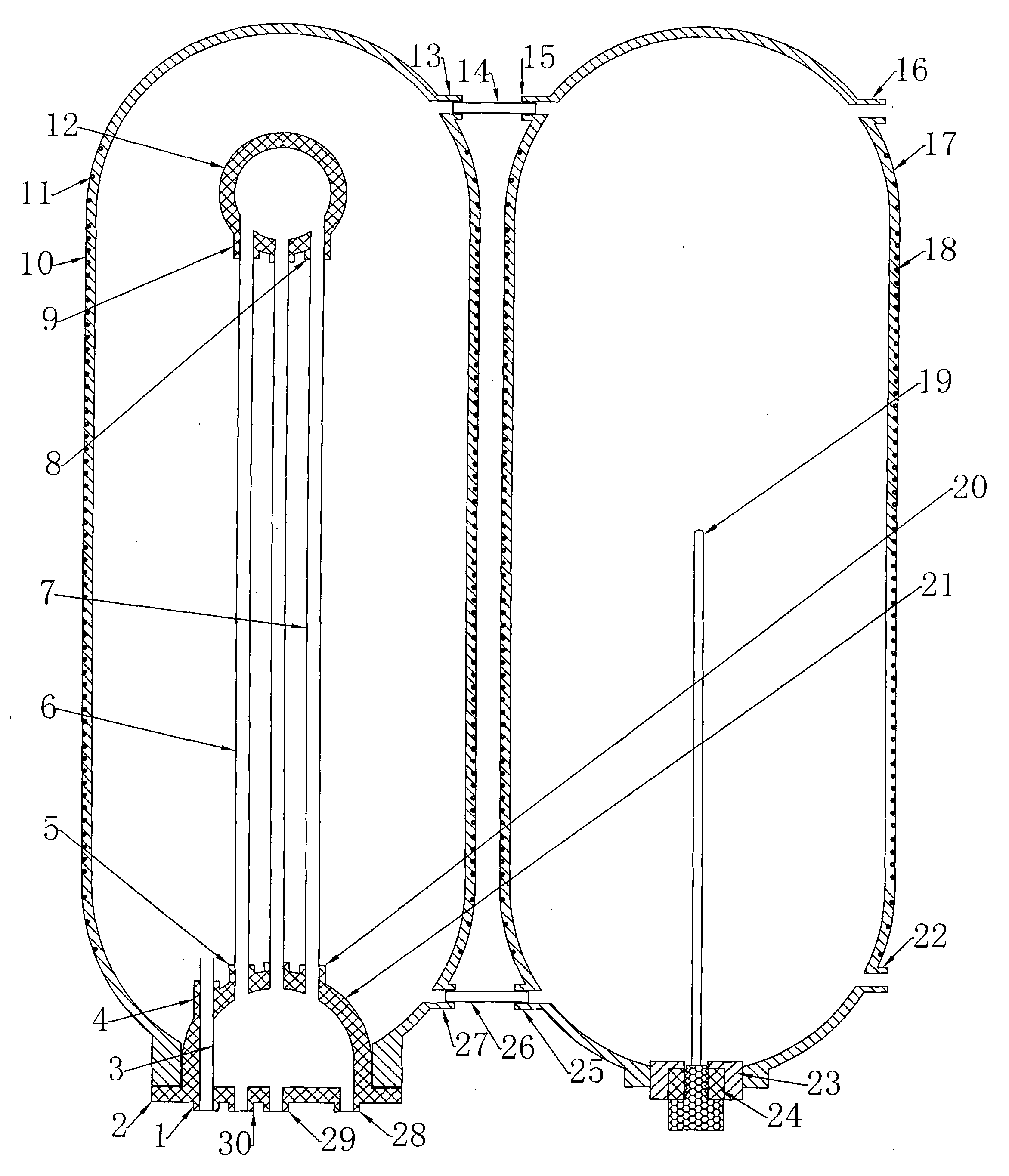

[0018] The attached drawings describe the structure of a double-barrel horizontal all-plastic pressure-bearing double-circulation liner. The wall of the first barrel 10 has a spiral reinforcement layer 11; the first barrel, the spiral reinforcement layer in the wall of the first barrel, and all the pipe joints on the first barrel are integrated blow molding, or integrated rotational molding, or Split injection molding; the second barrel 17 has a spiral reinforcement layer 18 in the wall; the second barrel, the reinforcement layer in the second barrel wall, and all the pipe joints on the second barrel are integrated blow molding or integrated rolling Plastic molding, or split injection molding; the first barrel is connected to the second barrel through the first barrel second connecting pipe interface 27, the second connecting pipe 26, and the second barrel second connecting pipe interface 25; the first barrel passes through the second barrel One barrel of first connecting pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com