Full-plastic pressure-bearing helical tube ball type dual-circulation liner

A technology of spiral tube and double circulation, applied in the field of spiral tube ball type all-plastic pressure-bearing double-circulation inner tank, can solve the problems of short life and high price of enamel inner tank, save metal raw materials, long life and small thermal resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

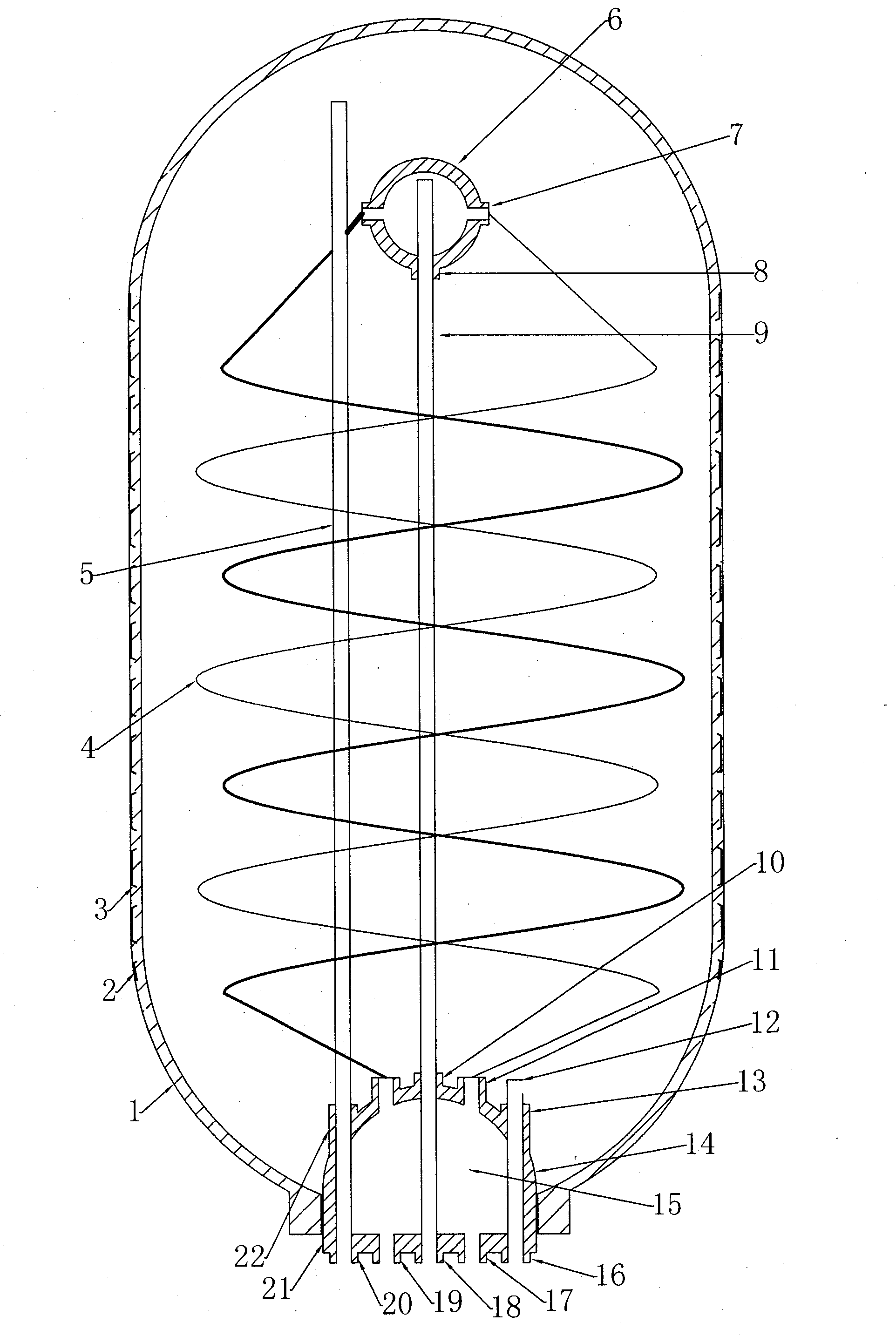

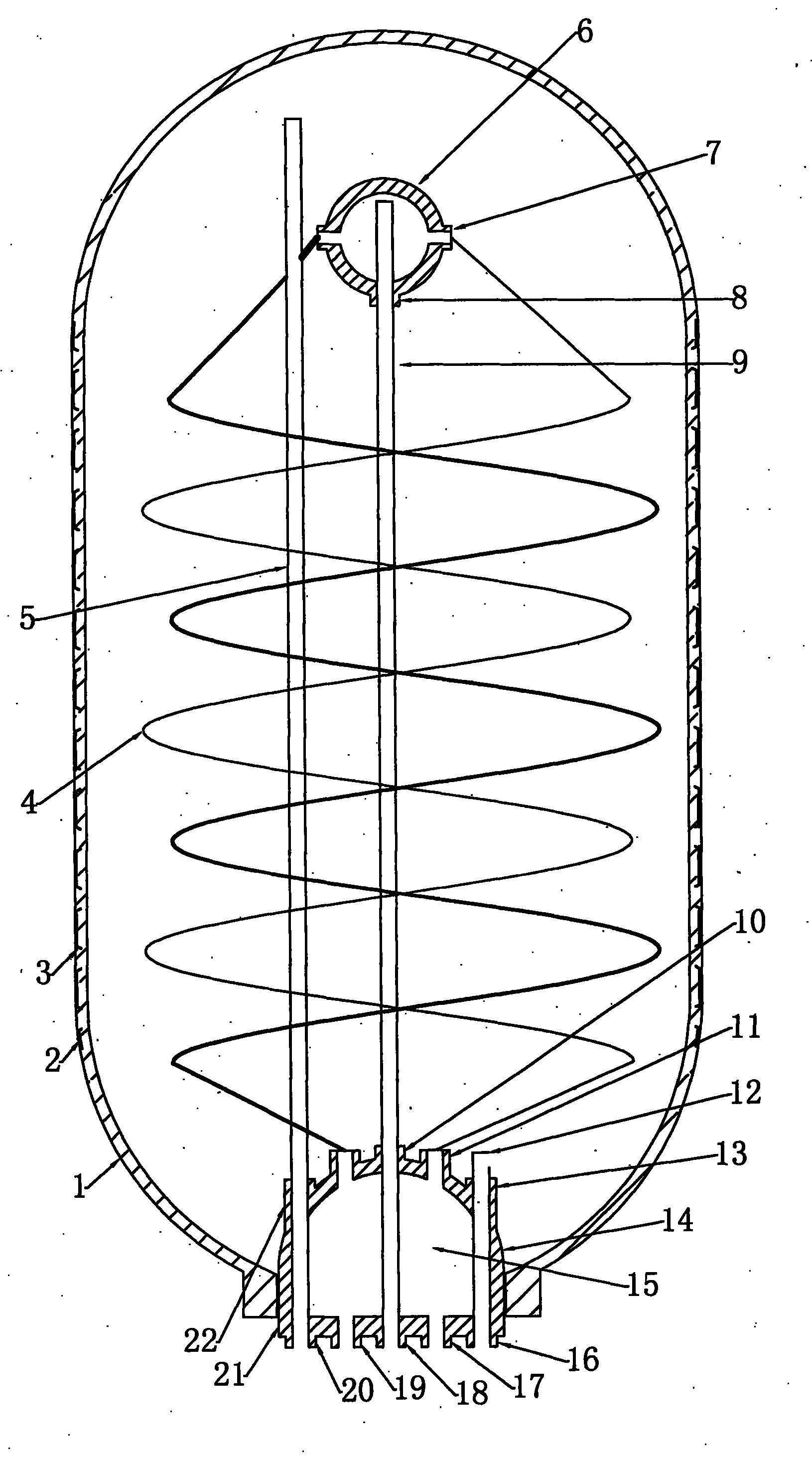

[0017] The accompanying drawings describe the structural form of a helical tube and ball all-plastic pressure-bearing double-circulation liner. The liner 1 is made of polymer material, or modified polymer material, or reinforced polymer material, or composite polymer material; there is a reinforcement layer 2 inside the wall of the liner 1, and a plurality of circular trusses or Pyramid-shaped holes 3; the reinforcing layer is spiral, or tubular, or ring-shaped, or reticular, or fiber-dispersed structure; the reinforcing layer is made of metal material, or glass fiber, or carbon fiber, or chemical fiber, or steel fiber, Or ceramic fiber material, or natural fiber material, or plant fiber, or fiber composite material; the reinforcement layer is outside the inner tank wall; the two ends of the inner tank are hemispherical; inner tank 1 and reinforcement layer 2 are integrated blow molding, Or integrated rotational molding, or separate injection molding; the base 21 is made of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com