Full-plastic pressure-bearing dual cycle spiral tube type split solar water heater

A technology for solar water heaters and solar thermal collectors is applied to solar thermal collectors, solar thermal collectors using working fluid, solar thermal energy, etc. Long, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

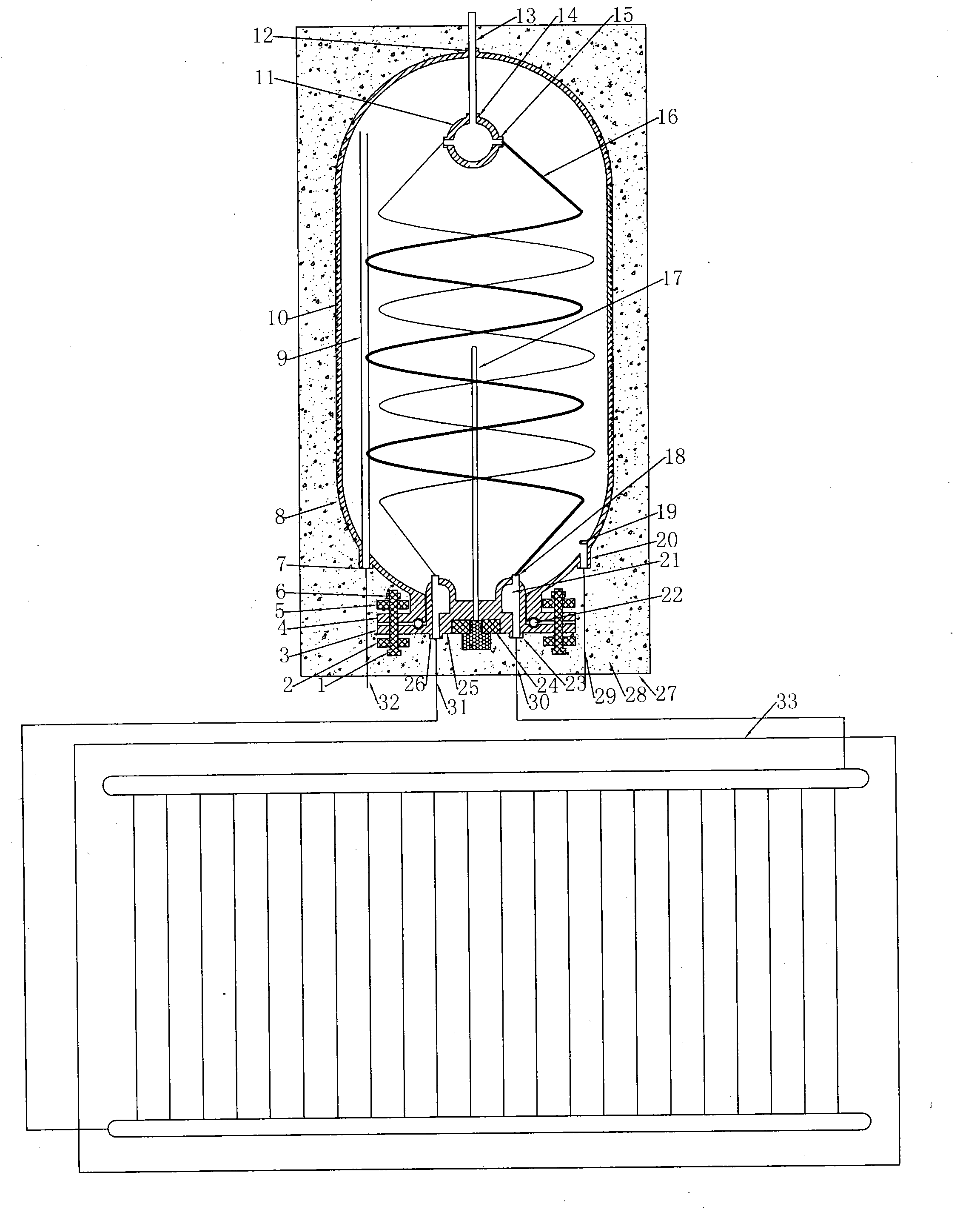

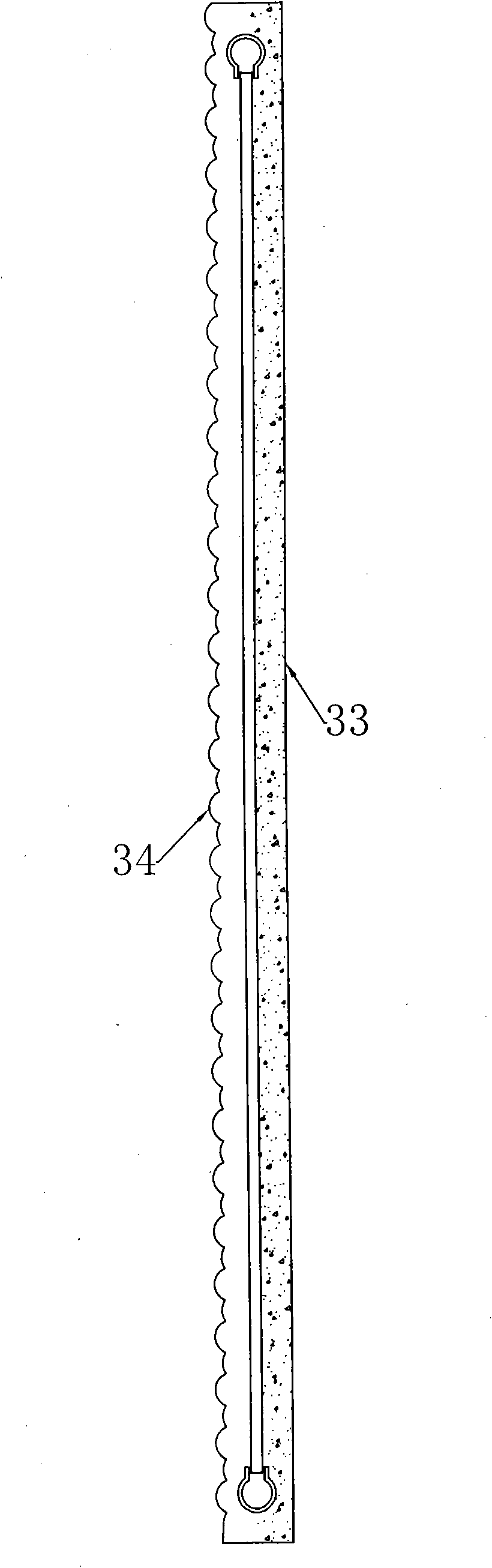

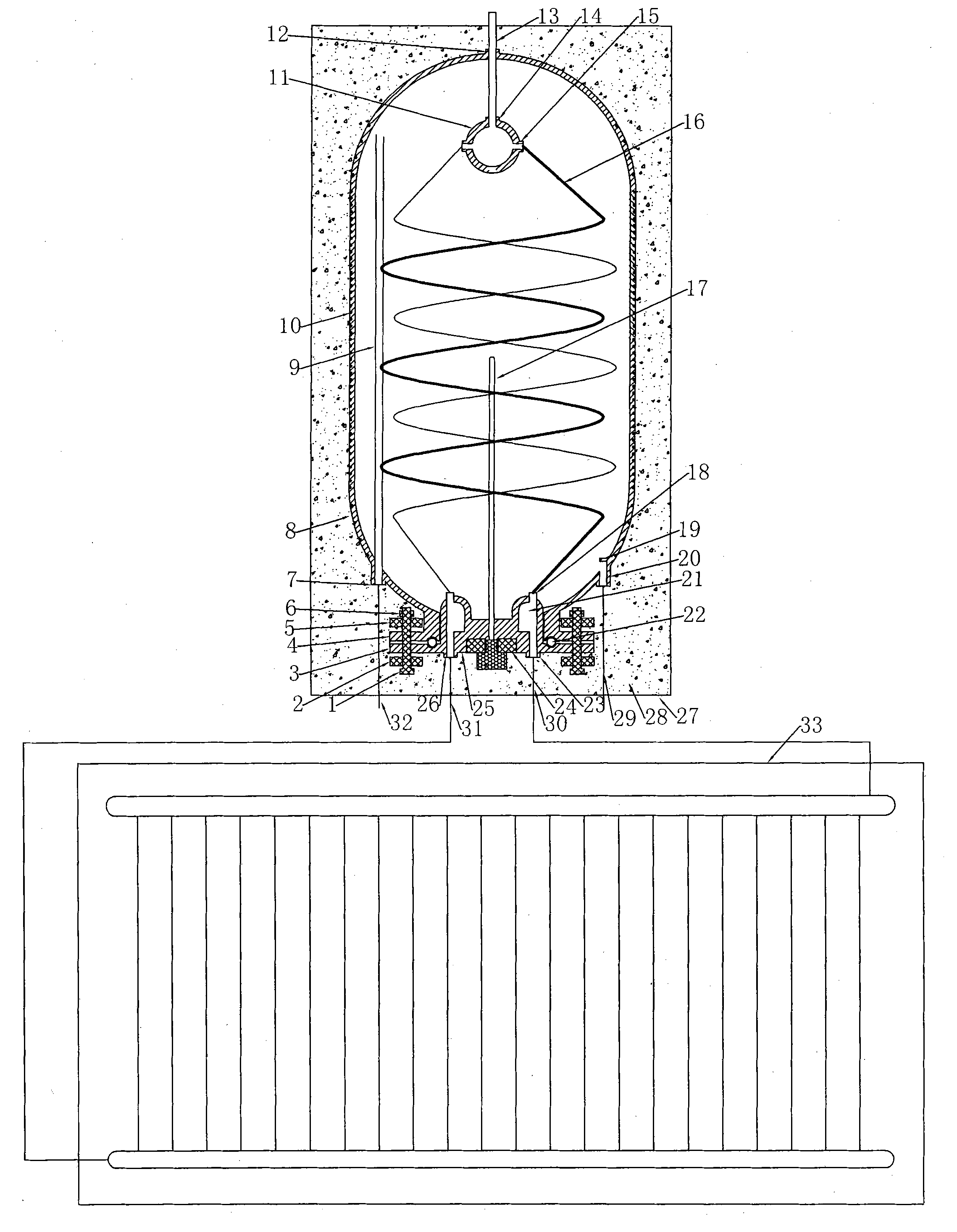

[0021] The accompanying drawings describe the structural form of an all-plastic pressurized double-circulation spiral tube split solar water heater. The reinforcing layer in the inner tank wall is a spiral, or tubular, or mesh, or fiber dispersed structure; the reinforcing layer in the inner tank wall is made of metal material, or glass fiber, or carbon fiber, or chemical fiber, or steel fiber , or ceramic fiber material, or natural fiber material, or plant fiber, or fiber composite material; the reinforcing layer in the inner tank wall can also be outside the inner tank wall; The spiral network reinforced layer 10 and all pipe joints on the inner tank wall together constitute the inner tank; the thermal insulation layer 28 fixes the inner tank in the middle of the water tank shell 27; the inner tank adopts polymer materials, or modified polymer materials, or reinforced high polymer materials Made of molecular materials or composite polymer materials; inner tank wall 8, inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com