Dehydrating and drying device for chemically plated small shaft

A drying equipment, dehydration and drying technology, applied to chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems affecting product quality, interfering with production, costing time and money, etc., to improve product quality , to ensure product quality, the effect of uniform drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

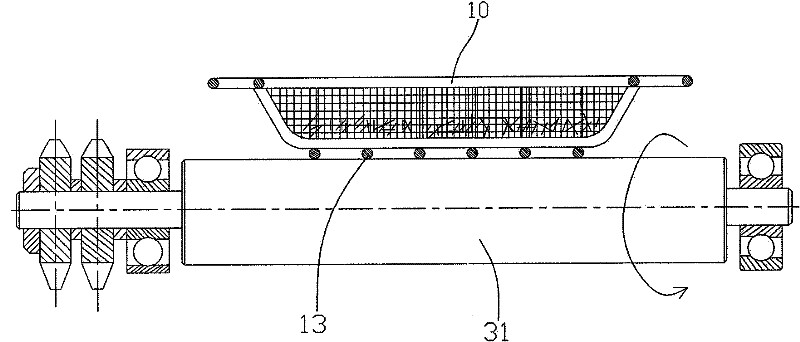

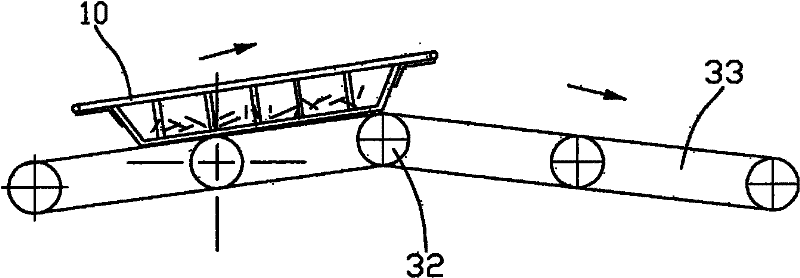

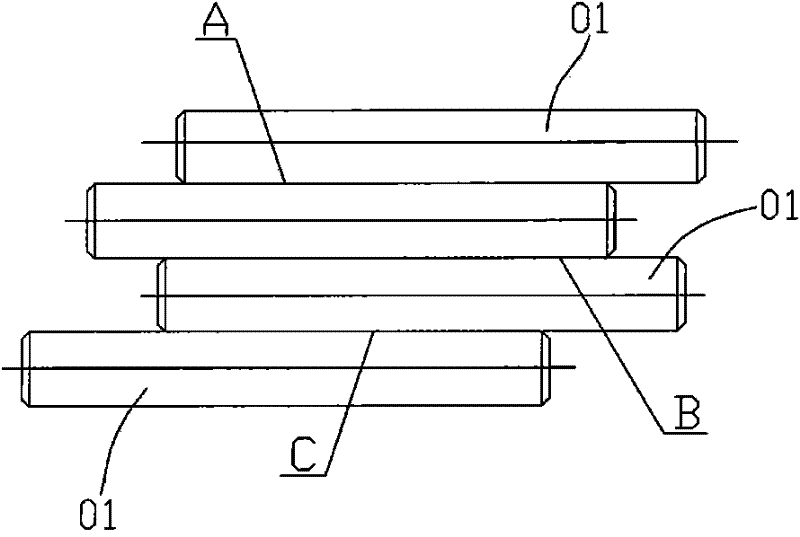

[0027] see attached Figures 2 to 6 Shown: the dehydration and drying equipment of the electroless plating small shaft of the present invention includes a dehydration drying basket 10, a shaking type rapid dehydration device 20, and a drum type dynamic drying device 30, wherein, the dehydration drying basket 10 inner substrate part The flat stainless steel wire mesh 11 is provided with stainless steel support plates 12 on both sides; the shaking type rapid dehydration device 20 is composed of a bracket 21, a roller slideway 22, a centrifugal type dehydrating fan 23, and a shaking mechanism 24. Among them, the dehydration drying basket 10 Placed on the roller slideway 22 supported by the bracket 21, two centrifugal dewatering fans 23 are arranged below the roller slideway 22, and a proximity switch 25 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com