Method and system for correction of extrapolated value of relaxation rate in stress relaxation test

A technology of stress relaxation and stress relaxation time, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems that plague the field of stress relaxation detection, and achieve the effect of improving confidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

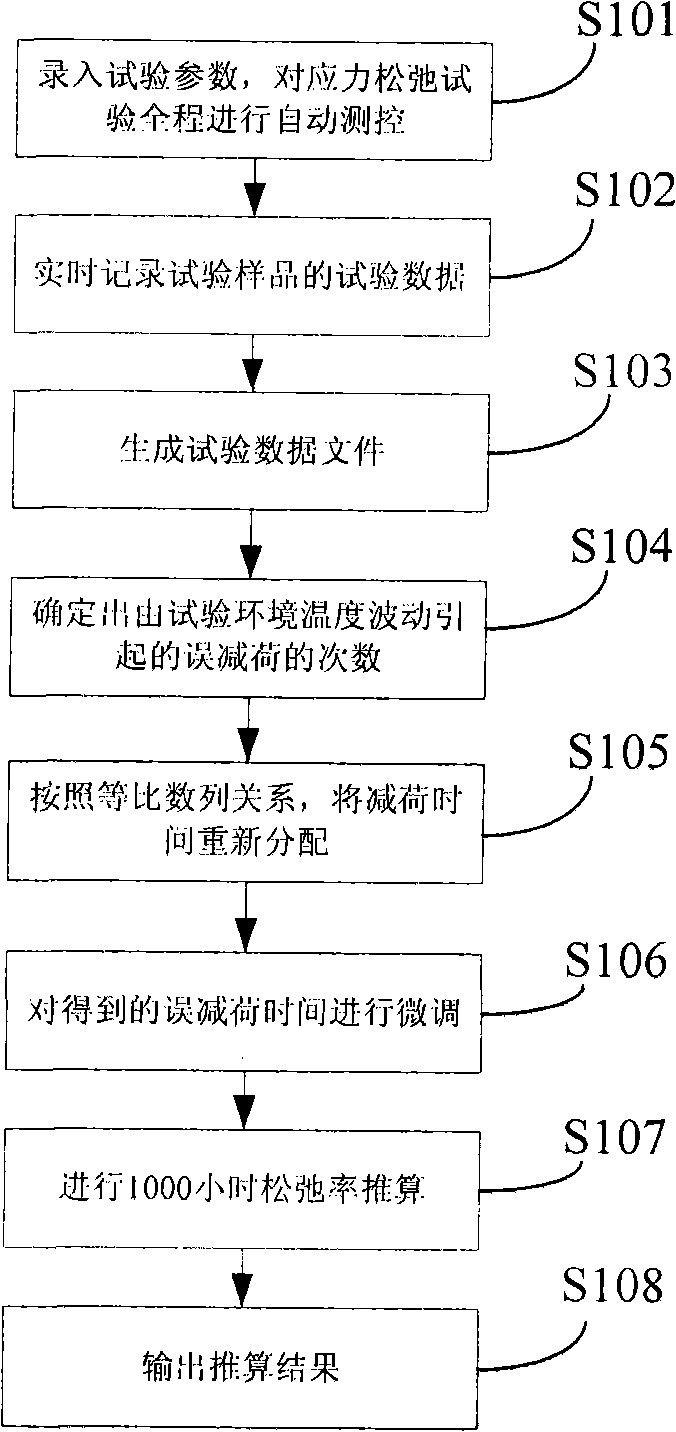

[0046] As the first embodiment of the present invention, when the stress relaxation test enters the stress relaxation plateau, the steps of judging whether the false load reduction caused by the temperature fluctuation of the test environment are as follows:

[0047] Analyze the stress relaxation time series. When the test enters the stable period of stress relaxation, if short-term frequent intensive unloading occurs, combine the test environment temperature sampling sequence and its corresponding time series to check whether the test environment temperature corresponding to the intensive unloading period has changed. , and then determine whether it is a false load reduction caused by the fluctuation of the test environment temperature.

[0048] As the second embodiment of the present invention, according to the geometric sequence relationship, these deloading times are redistributed to the time period between the previous deloading of the group of false deloading and the reap...

no. 5 example

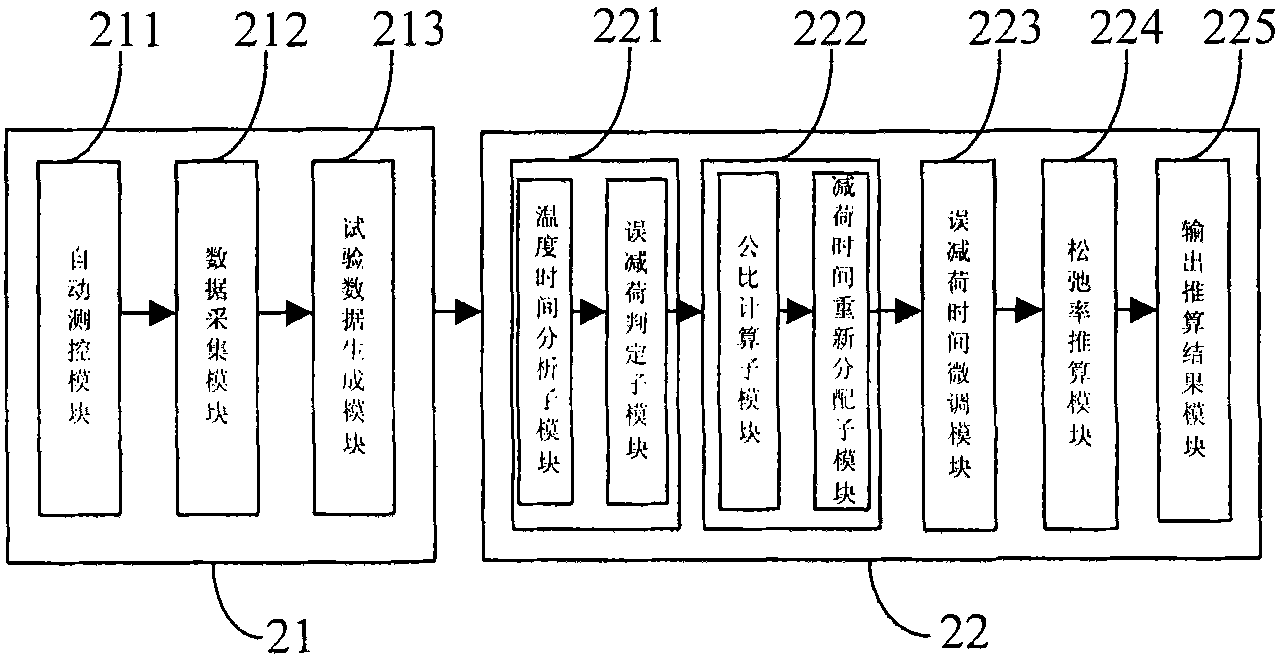

[0069] As the fifth embodiment of the present invention, the false load shedding judgment module includes:

[0070] The temperature time analysis sub-module is used to obtain the test environment temperature sampling sequence and its corresponding time, and analyze the test environment temperature sampling sequence and its corresponding time.

[0071] The false load reduction judgment sub-module is used to determine whether the short-term frequent intensive load reduction that occurs after the test enters the stable stress relaxation period is a false load reduction caused by the temperature fluctuation of the test environment.

no. 6 example

[0072] As the sixth embodiment of the present invention, the off-load time allocation module includes:

[0073] The common ratio calculation sub-module is used for the calculation of the common ratio in the geometric sequence.

[0074] Unloading time redistribution sub-module, which is used to redistribute the unloading time to the time period between the previous unloading of a certain group of wrong unloading and the reappearance of unloading after this group of wrong unloading, and at the same time ensure that the unloading of this group The number of loads remains unchanged.

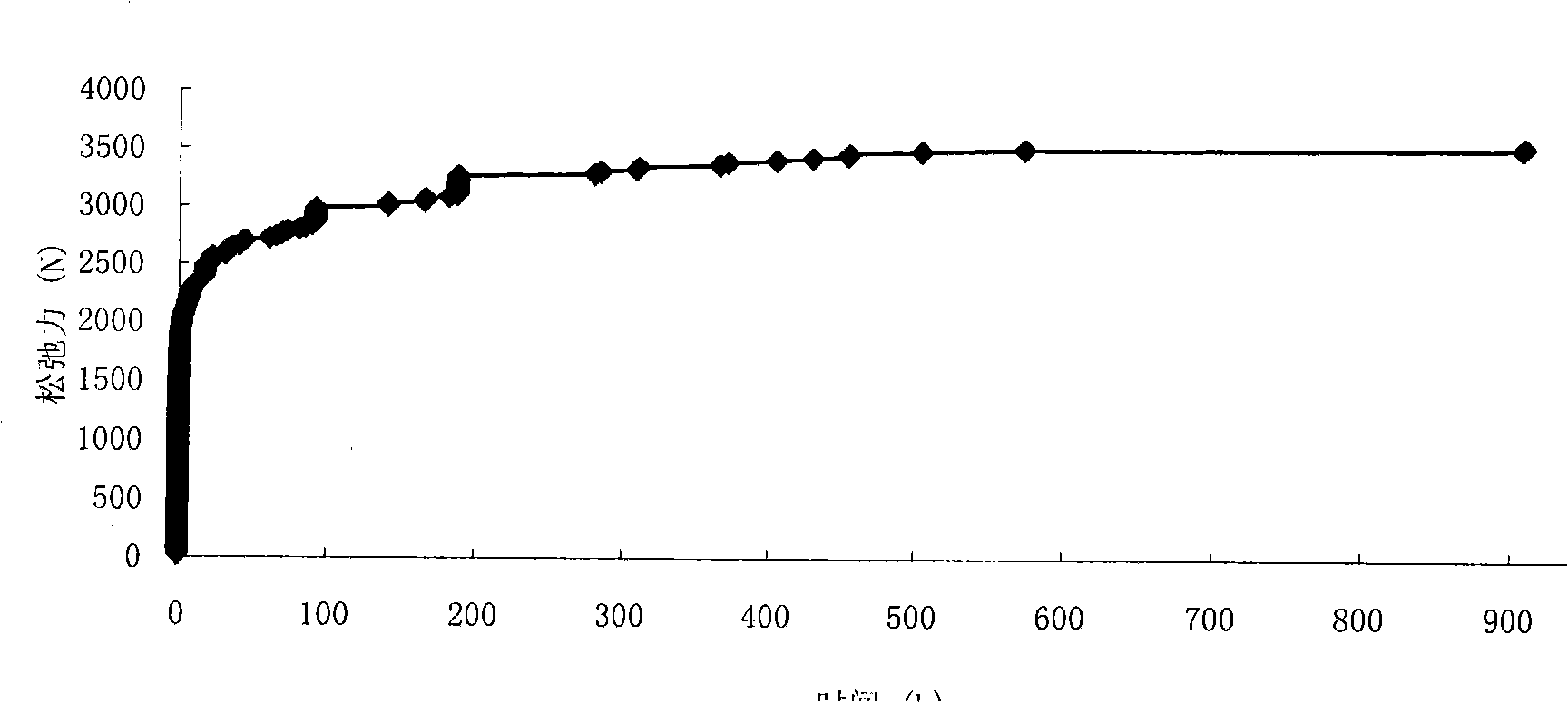

[0075] Figure 3-Figure 6 The results obtained by processing the data obtained from the 1000-hour stress relaxation test of a certain test sample are shown.

[0076] image 3 and Figure 4 It is the result of standard derivation on the original test data.

[0077] Figure 5 and Figure 6 It is the result derived from standard derivation after using the embodiment of the present invention to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com