Composite paraboloidal photovoltaic hot-water heat collector

A compound parabola and heat collector technology, applied in the field of solar energy utilization, can solve problems such as the decline of photovoltaic efficiency, achieve the effects of reducing calorific value, improving comprehensive utilization efficiency, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

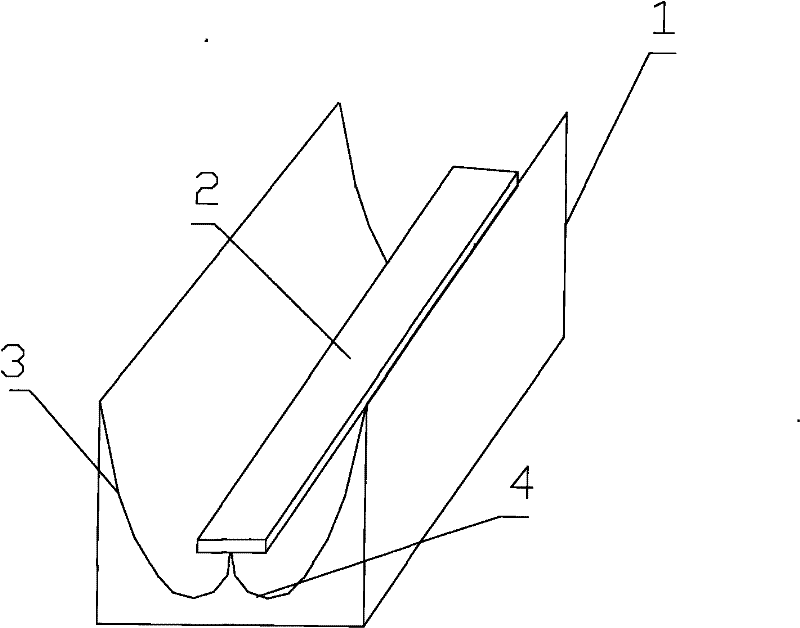

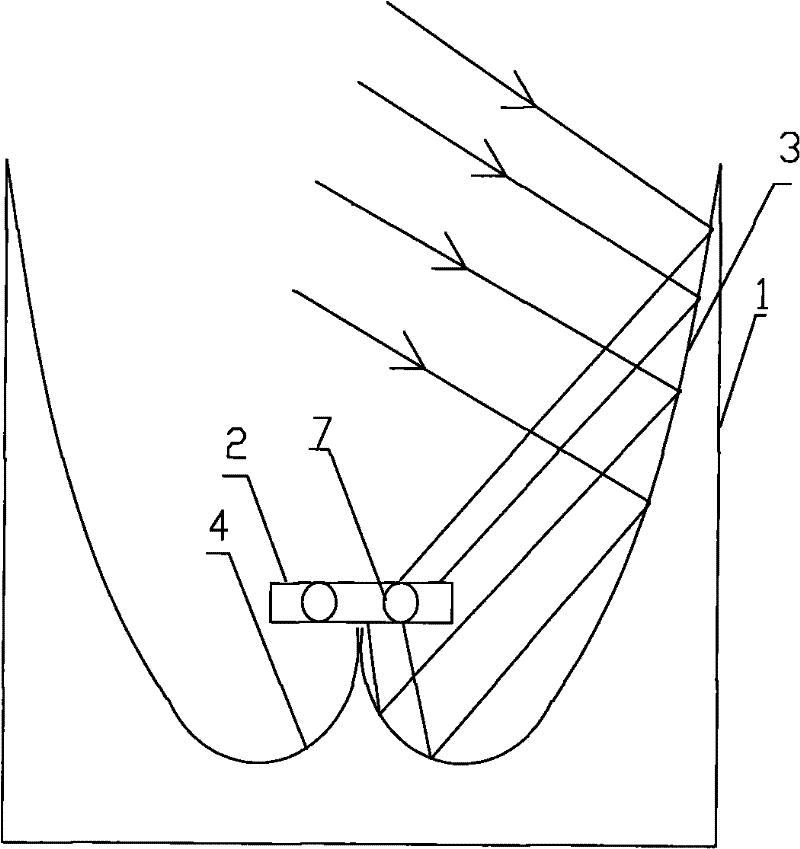

[0026] see figure 1 , the composite parabolic photovoltaic hot water collector includes a curved reflector and a photovoltaic absorber 2 .

[0027] The cross-section of the curved reflector is W-shaped, and it is located in the frame 1; the curved surfaces on both sides are paraboloids 3, and the curved surfaces on both sides of the inner bend at the bottom are circular involute curved surfaces 4, and the connection between the parabolic surface and the circular involute curved surface Smooth transitions.

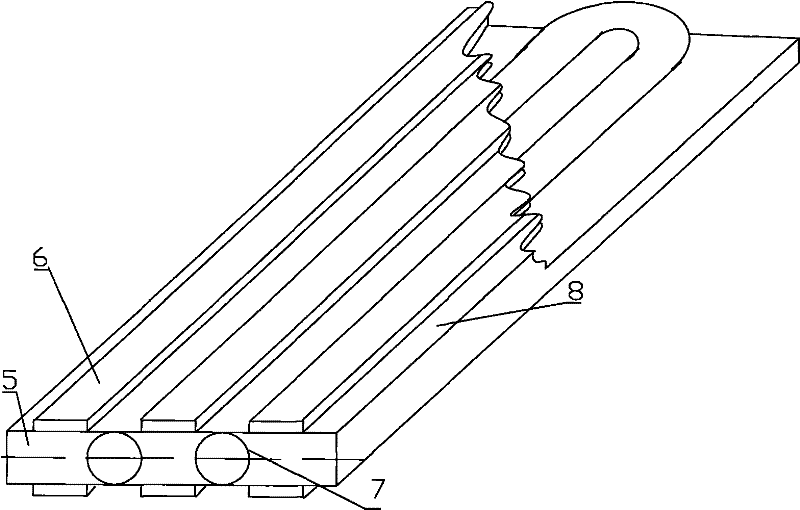

[0028] see figure 2 , The photovoltaic absorber 2 includes a U-shaped tube 7, and the U-shaped tube 7 is located between two layers of battery panels 8, and the battery panels 8 are thin aluminum plates. A thermal insulation material 5 is filled between the U-shaped tube 7 and the two-layer battery board 8; three-way photovoltaic cells 6 are evenly distributed on the outer surfaces of the two-layer battery board 8, and the three-way photovoltaic cells 6 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com