Fabric knitting method, and weft knitting machine

A flat knitting machine and knitted fabric technology, which is applied in the directions of knitting, weft knitting, textiles and papermaking, can solve problems such as breakage and bending of the needle guide, so as to prevent the needle from being caught and avoid the needle guide. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]

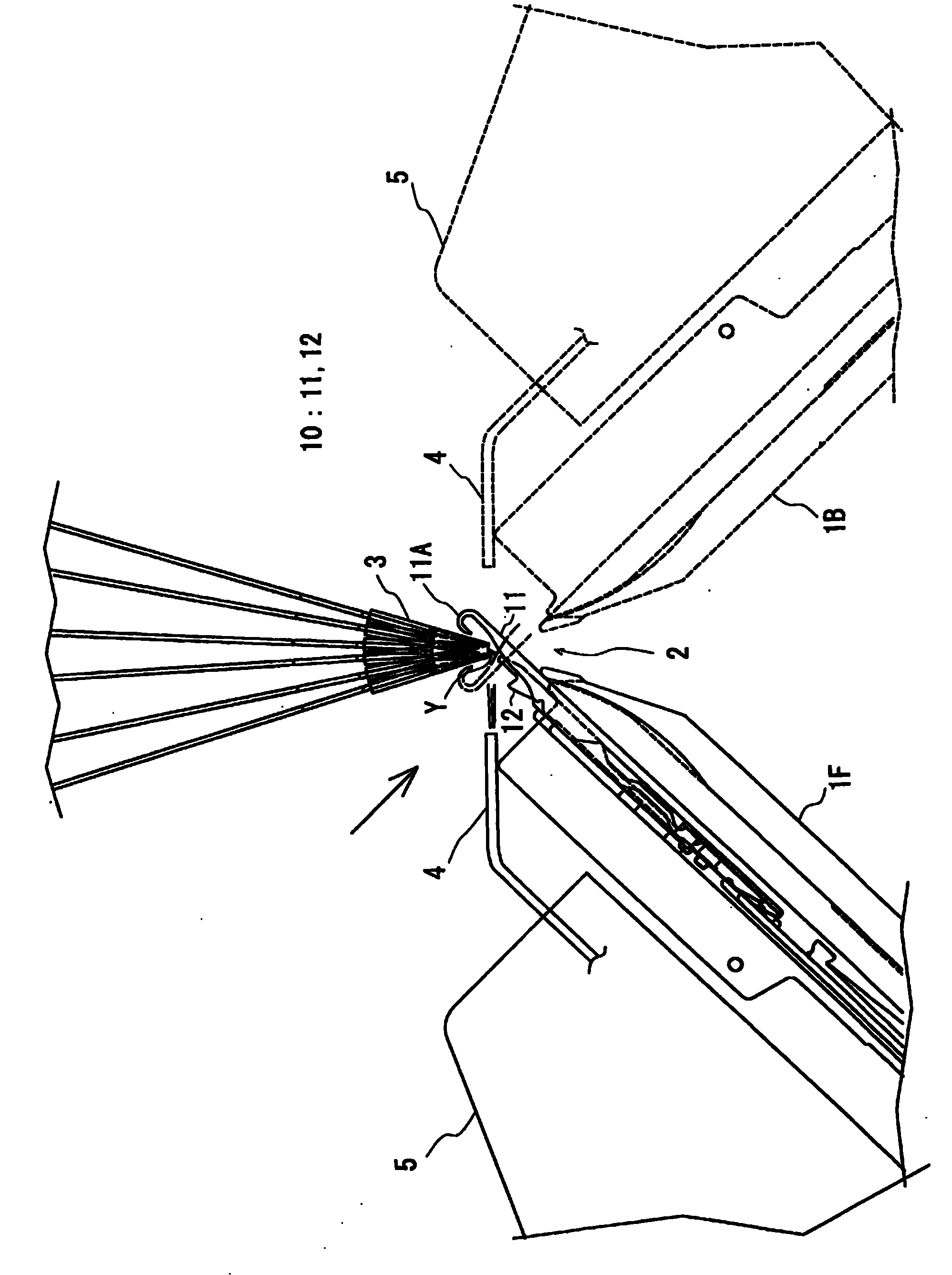

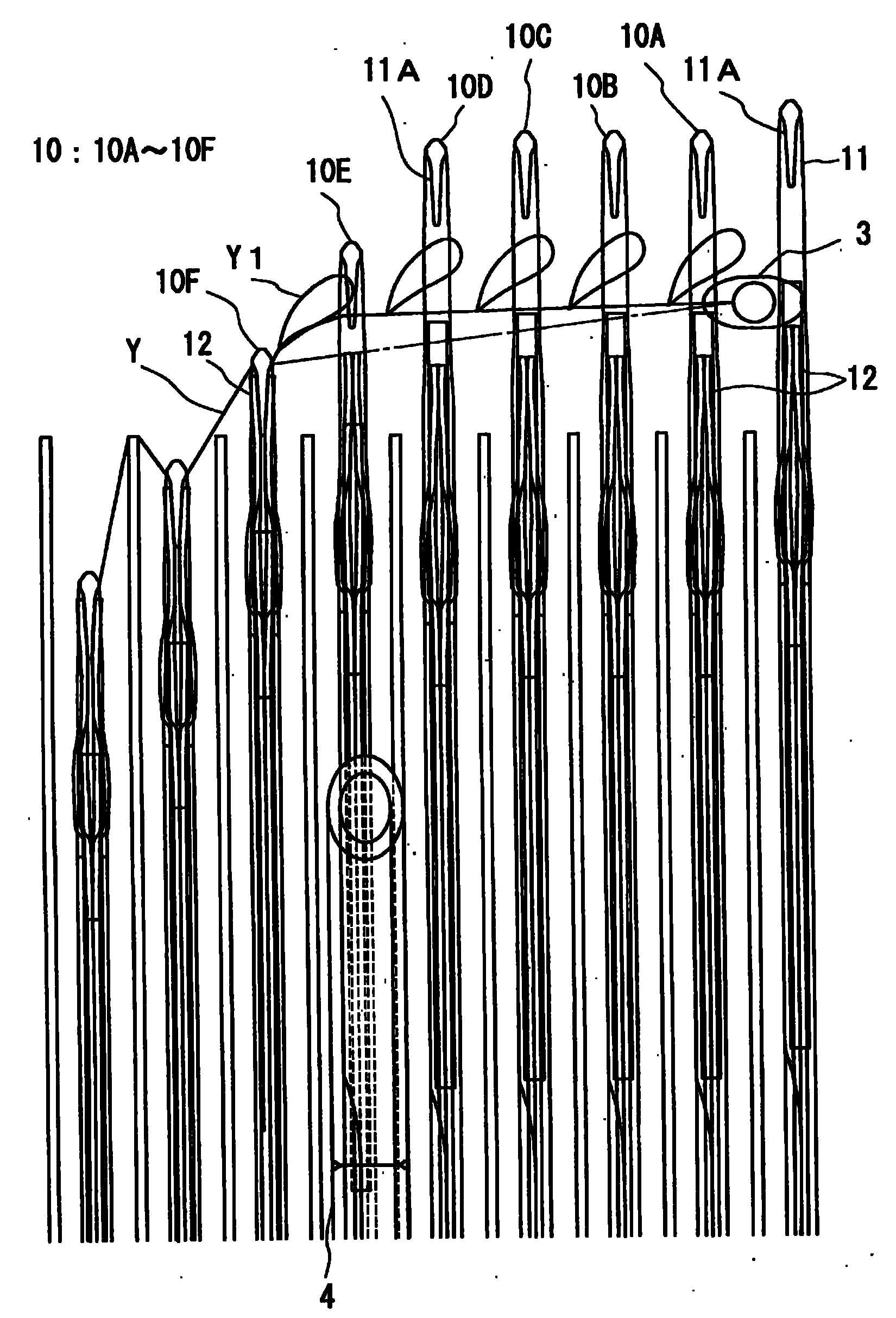

[0033] The flat knitting machine of this embodiment includes: a pair of needle beds 1F, 1B in which a plurality of compound needles 10 are arranged in a row; The air nozzle 4 that presses the decorative yarn portion Y1 that protrudes toward the outer periphery of the fancy twist yarn Y, and the carriage 5 that reciprocates in the longitudinal direction of the needle beds 1F, 1B. Below, based on figure 1 , 2 Each configuration of the flat knitting machine of this embodiment will be described in detail.

[0034] Such as figure 1 As shown, the compound needle 10 includes a needle body 11 and a slider 12 . The needle main body 11 has a hook portion 11A at its front end, and the slider 12 is, for example, a pair of thin plates fitted into a groove of the needle main body 11 . By the relative sliding of the needle body 11 and the slider 12 in the longitudinal direction, the hook portion 11A provided at the tip of the needle body 11 is opened and closed. Specifically,...

Embodiment 2

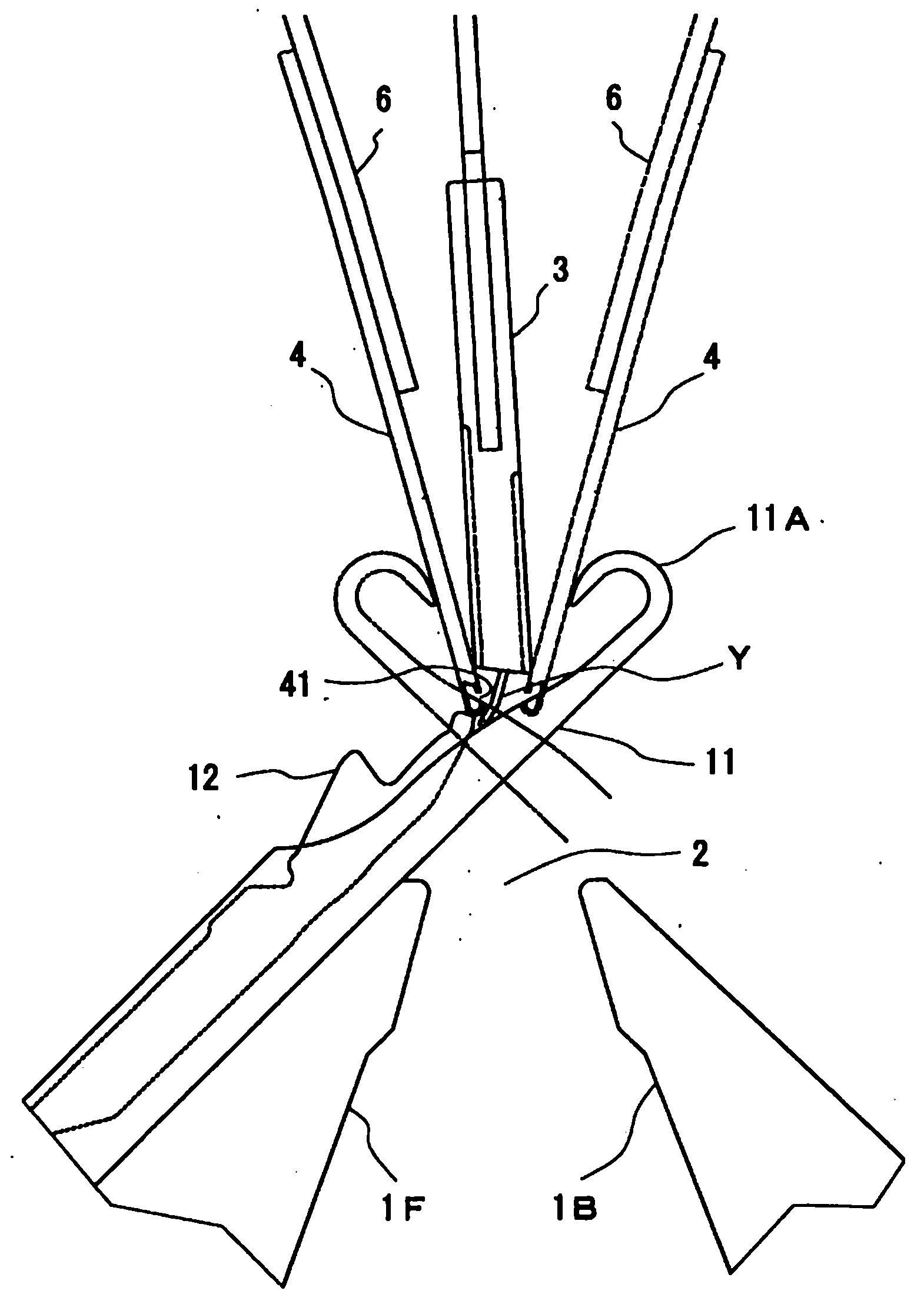

[0054] Next, based on image 3 An embodiment of the present invention in which an air nozzle is provided instead of a part of the yarn supplying member will be described. In this embodiment, the basic structure and functions are the same as those of the first embodiment, except that the structure and installation position of the air nozzles are different from those of the first embodiment. The following description will focus on the differences from the first embodiment.

[0055]

[0056] The yarn supply member 3 is slidably supported on a plurality of yarn guide rails (not shown) extending in the longitudinal direction of the needle bed substantially above the needle mouth portion 2 . The carrier rails are aligned in a direction perpendicular to the longitudinal direction of the needle beds 1F, 1B, and here, the nozzle brackets 6 are held using the carrier rails positioned at ends in the alignment direction, and the yarn supplying member 3 is held on the remaining yarn ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com