Device and method for dredging discharge valve of polyurethane foam gap filler pot

A polyurethane foam and discharge valve technology, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of foam sealant tank discharge valve sticking, difficult to remove, and inconvenient to use. Achieve the effect of increasing service life, convenient installation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment and with reference to accompanying drawing:

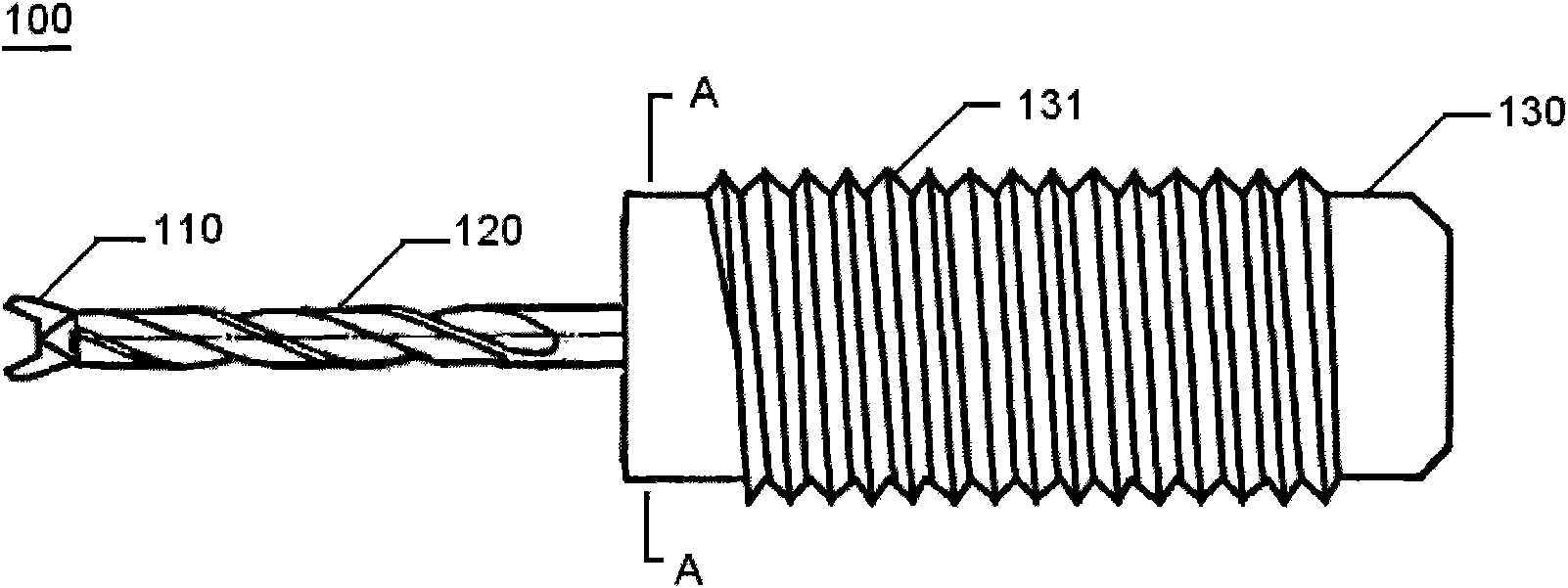

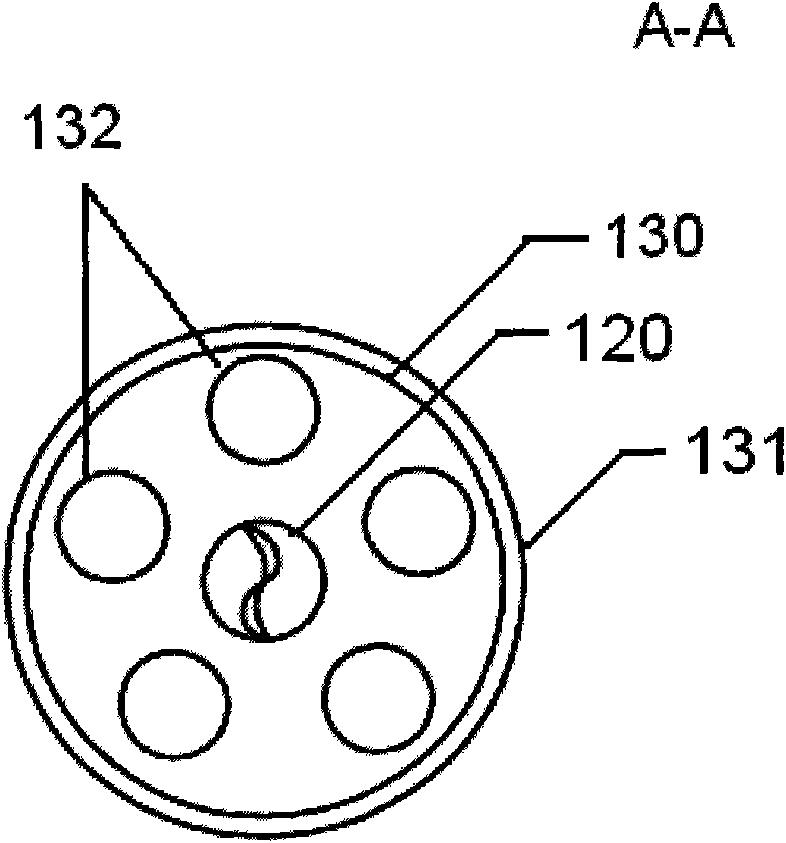

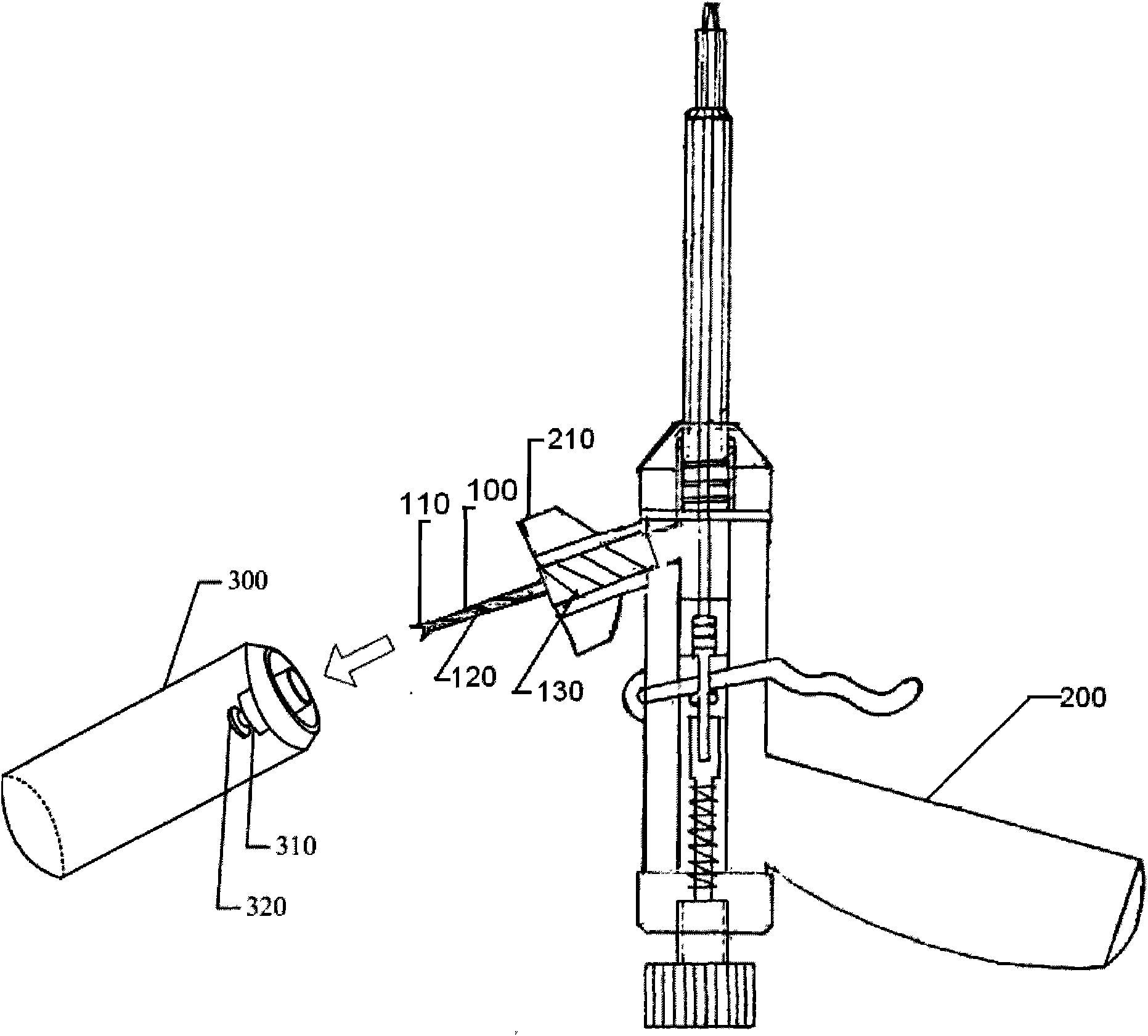

[0019] see figure 1 as shown, figure 1 It is a structural schematic diagram of the device for dredging the discharge valve of the polyurethane foam caulk tank according to the present invention. A device 100 for dredging the discharge valve of a polyurethane foam caulk tank, the device 100 at least includes a drill bit 110, a drill body 120 and a drill handle 130, the drill bit 110 is located at the front end of the drill body 120, and the drill handle 130 is arranged on At the rear end of the drill body 120, a feed groove is arranged on the drill body 120, and the feed groove is helical and distributed continuously around the entire drill body. The drill bit 110 is V-shaped, the outer surface of the drill shank 130 is provided with a thread structure 131 , and the axial direction of the drill shank 130 is provided with several through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com