Hydraulic working roll bending device for cold-rolling mill

A technology of work rolls and cold rolling mills, which is applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., and can solve problems such as difficult control of product quality, difficult control of work roll arcs, and impact on strip quality, etc. Achieve the effects of high work efficiency, simple structure and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

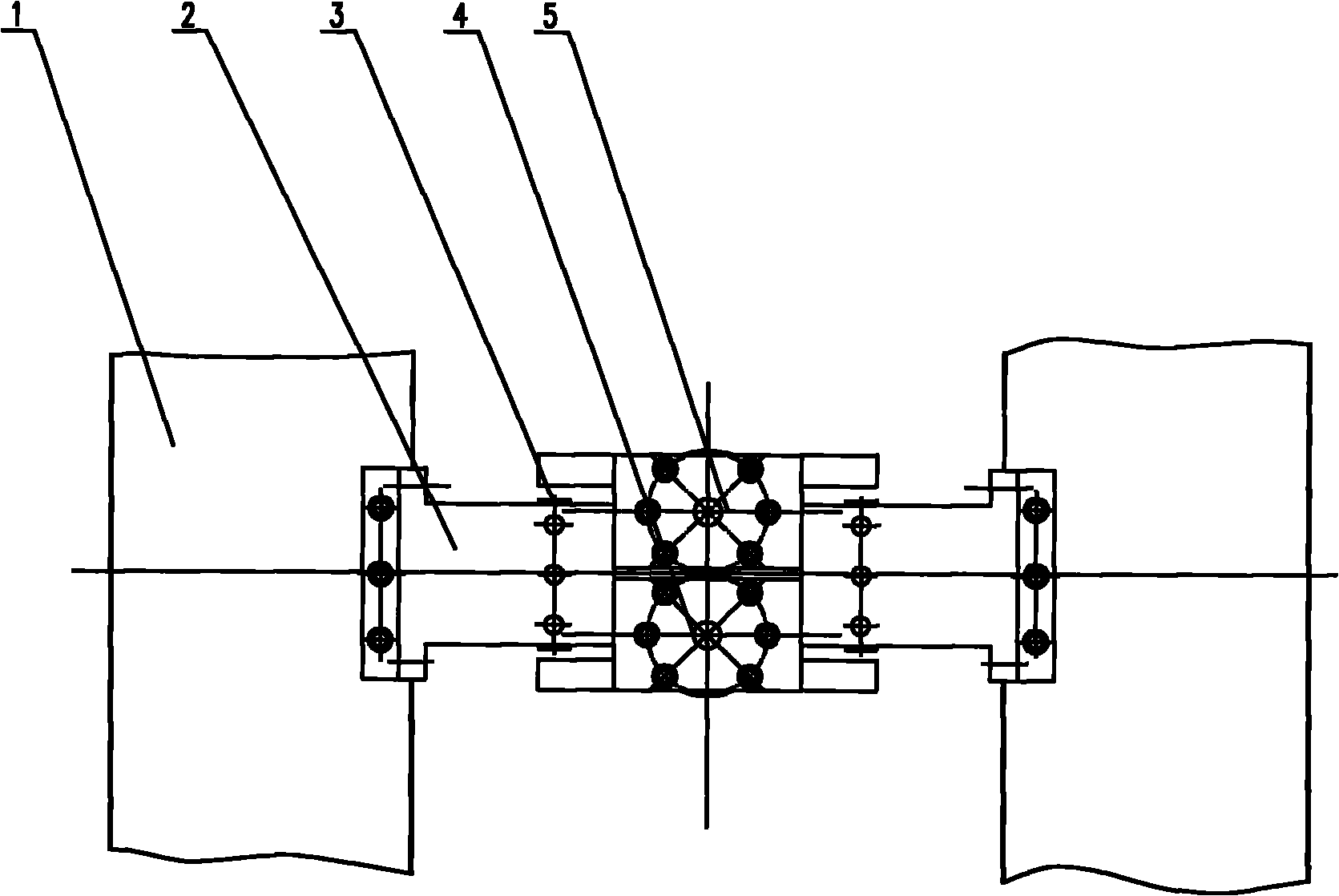

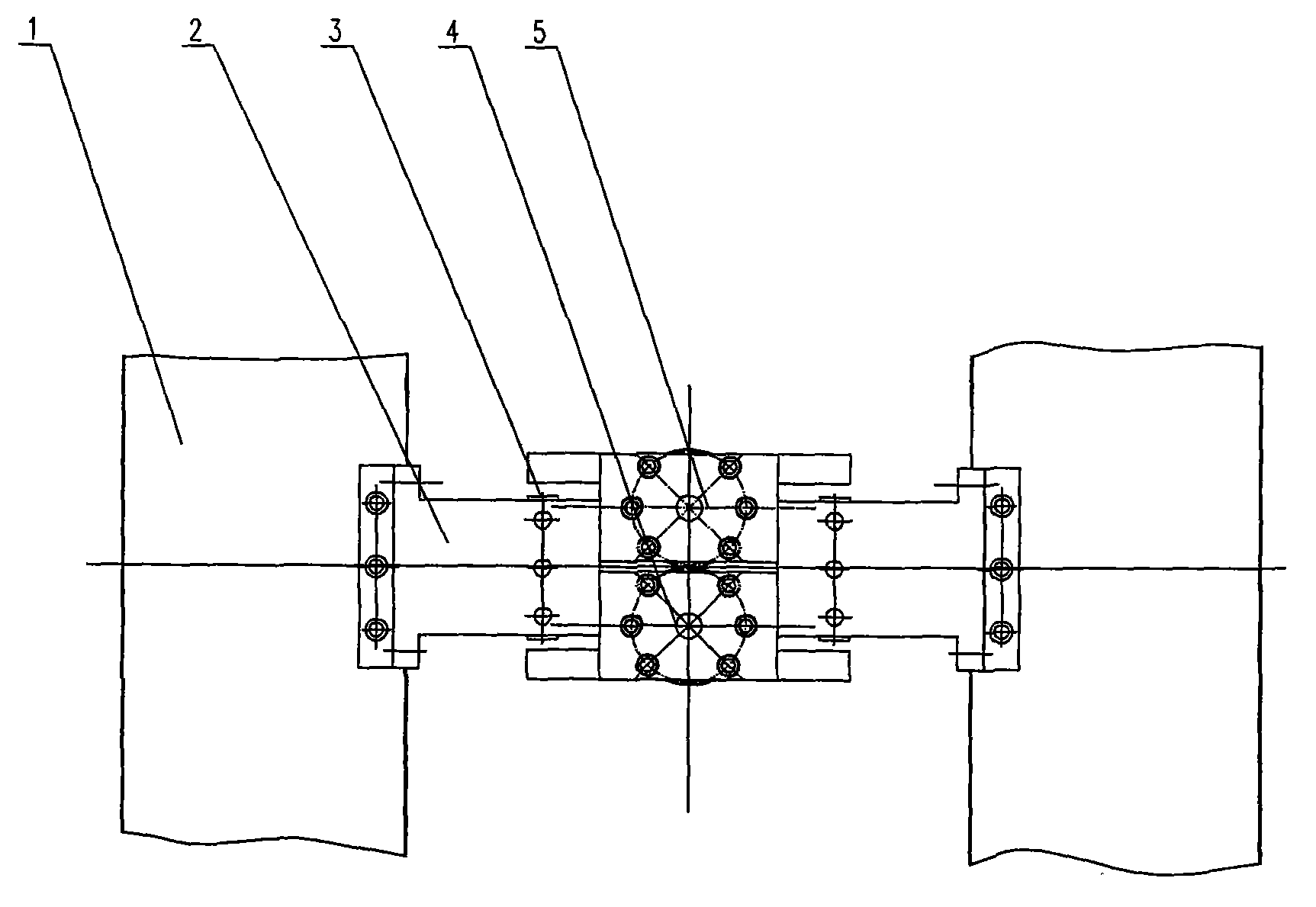

[0009] like figure 1 Shown: including frame 1, insert 2, bending cylinder 3, lower work roll system 4 and upper work roll system 5.

[0010] The present invention adopts the bending oil cylinder 3 to be installed in the insert 2, and the insert 2 is installed on the frame 1 with screws, and the lower work roll system 4 and the upper work roll system 5 are installed between the two insert blocks 2.

[0011] exist figure 1 When the cold rolling mill needs to roll a strip of a certain specification, the solenoid valve of the roll bending cylinder is first opened to make the roll bending cylinder 3 act, the piston rod is stretched out (both sides of the bending roll cylinder work at the same time), and the piston rod pushes down The two wings of the chocks of the work roll system 4 and the upper work roll system 5 are properly adjusted so that a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com