Ship unloading equipment applicable to various kinds of dried bulk cargo

A kind of equipment and drying technology, applied in the field of dry bulk cargo logistics, which can solve the problems of occupying shoreline resources, easy to raise dust, and cargo pollution to ports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

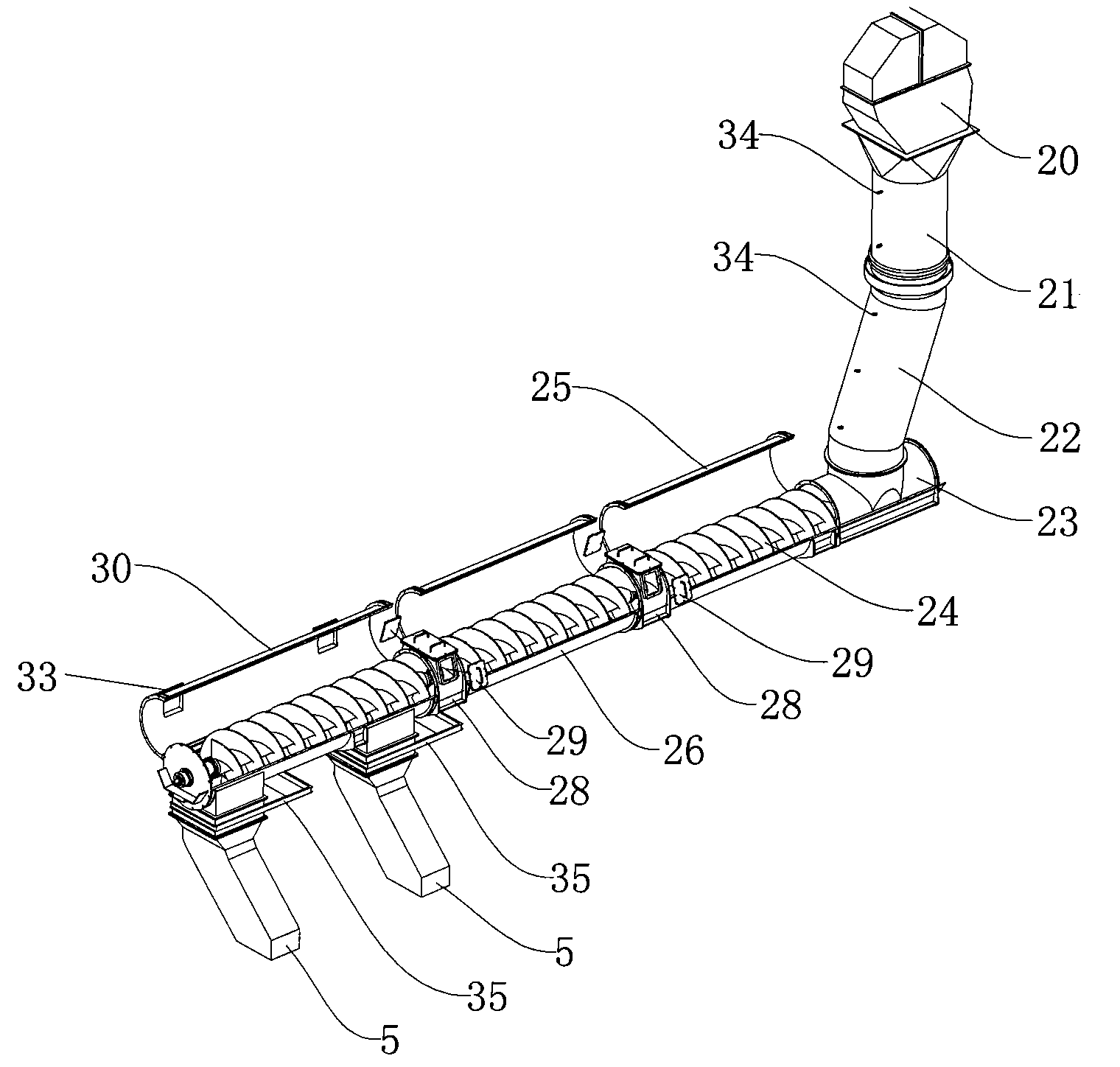

[0025] Specific embodiment 1: There are two outlets on the lower end surface of the base 31, and the two outlets are respectively connected to the two cargo discharge pipes 5 in one-to-one correspondence, and the inlets of the two cargo discharge pipes 5 are equipped with push-pull gate valves 35. Observation window covers 33 are respectively opened at the positions facing the two outlets of the upper half pipe 30;

[0026] Its working principle is as follows: two cargo discharge pipes 5 convey dry bulk cargo respectively, and each cargo discharge pipe 5 conveys a single dry bulk cargo, and the dry bulk cargo transported through the pipeline must correspond to one of the cargo discharges. The opening of the feed port of the cargo discharge pipe corresponding to the dry bulk cargo is controlled by the push-pull plate valve 35, and the feed port of the non-corresponding cargo discharge pipe is closed.

specific Embodiment 2

[0027] Embodiment 2: There is an outlet on the lower surface of the base 31, the outlet is connected to two cargo discharge pipes 5, and a rotatable valve plate 36 is installed at the outlet, and the area of the valve plate 36 can completely cover a single cargo discharge pipe 5, the upper half pipe 30 has an observation window cover 33 facing the position of the outlet.

[0028]Its working principle is as follows: two cargo discharge pipes 5 convey dry bulk cargo respectively, and one cargo discharge pipe 5 conveys a kind of dry bulk cargo, and the dry bulk cargo transported through the pipeline must correspond to one of the cargo outlets. The material pipe closes the feed port of its uncorresponding cargo discharge pipe through the rotatable valve plate 36, thereby opening the feed port of its corresponding cargo discharge pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com