Ethionine resistance Candida utilis and application thereof

A technology of Candida utilis and ethionine, applied in fermentation, biochemical equipment and methods, microorganisms, etc., to achieve high yield, strong protein synthesis ability, and broad growth nutrition spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

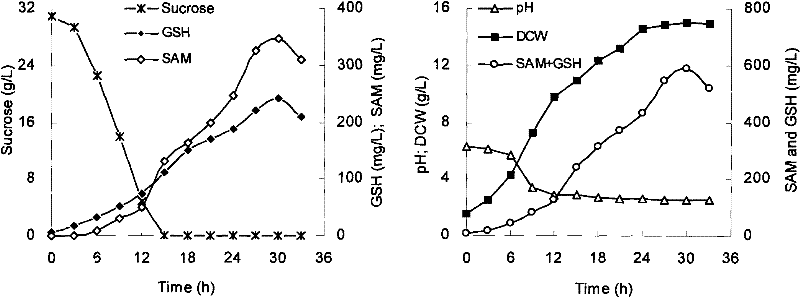

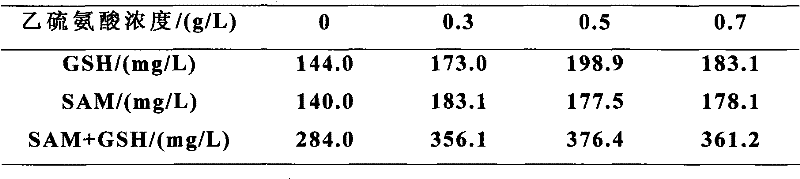

[0029] Example 1: Co-production and fermentation of SAM and GSH, and determining the optimal concentration of ethionine

[0030] (1) Strain

[0031] The starting strain is Candida utilis SZU 07-01, preserved by the Industrial Microbiology Laboratory of Soochow University.

[0032] (2) Medium

[0033] Slope and seed culture medium (g / L): glucose 20, peptone 20, yeast extract 10, pH 6.0;

[0034] Screening medium: Add 0~0.7g / L ethionine to the seed medium;

[0035] Fermentation medium before optimization (g / L): glucose 30, ammonium sulfate 8, potassium dihydrogen phosphate 3, magnesium sulfate 0.25, pH 5.5.

[0036] (3) UV mutagenesis

[0037] The irradiation was carried out under a Philips ZWSSJD-30 ultraviolet lamp, the irradiation power and wavelength were 30W, 253.7nm, and the irradiation distance was 30cm. The specific steps are as follows: aspirate 1 mL of seed culture solution after 20 hours of culture, centrifuge for 2 min at 10000 r / min, discard the supernatant, add sterile saline ...

Embodiment 2

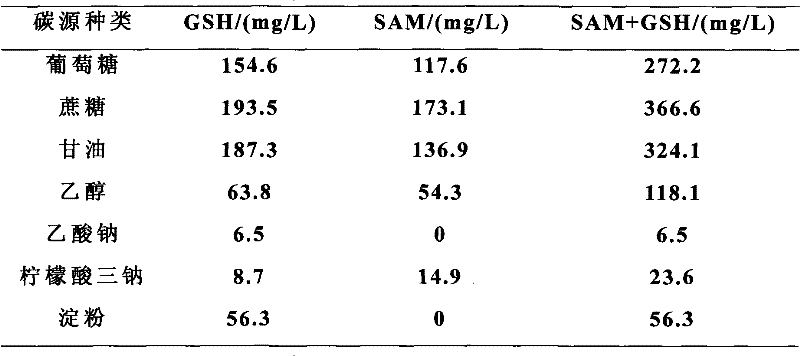

[0064] Example 2: Determine the best carbon source

[0065] The operation was carried out according to Example 1, but the difference was that the fermentation medium before optimization was used as a benchmark to investigate the effects of different carbon sources (carbon sources were glucose, sucrose, glycerol, ethanol, sodium acetate, sodium citrate and starch) on SAM and GSH. The impact of co-production fermentation, on this basis, the experimental results of co-production fermentation to prepare SAM and GSH, the results are shown in Table 2:

[0066] SAM output: 0~173.1mg / L; GSH output: 6.5~193.5mg / L;

[0067] SAM and GSH co-production total 6.5~366.6mg / L;

[0068] Among them, the best carbon source is sucrose.

[0069] Table 2 The effect of carbon source types on the co-production and fermentation of SAM and GSH

[0070]

Embodiment 3

[0071] Example three, determine the best nitrogen source

[0072] The operation was carried out according to the first embodiment, the difference is: the fermentation medium before optimization was used as a benchmark to investigate the effect of different nitrogen sources (the nitrogen sources are yeast extract, beef extract, peptone, potassium nitrate, ammonium sulfate, urea and ammonium nitrate) on SAM The effect of co-production and fermentation with GSH. On this basis, the experimental results of co-production and fermentation to prepare SAM and GSH are shown in Table 3:

[0073] SAM output: 41~146mg / L; GSH output: 57.5~167.7mg / L;

[0074] The combined production of SAM and GSH is 90.5~308.7mg / L;

[0075] Among them, the best nitrogen source is ammonium sulfate.

[0076] Table 3 The effect of nitrogen sources on the co-production and fermentation of SAM and GSH

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com