Minitype axial flow fan with C spline bent blades

A technology of micro shafts and blades, which is used in the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc. The choice of blade height is not quantified and clear, the accurate mathematical characteristics of the bending profile are not specified, and the end loss at the blade root cannot be effectively reduced, so as to enhance the anti-stall performance, strong adaptability to changing conditions, and improve aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. However, this embodiment is not intended to limit the present invention, and all similar structures and similar changes of the present invention shall be included in the protection scope of the present invention.

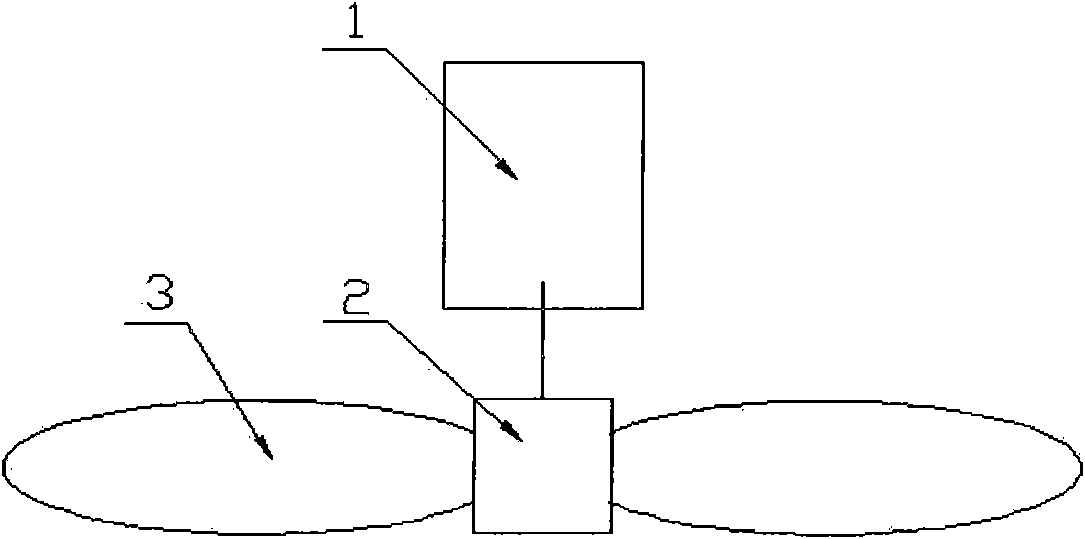

[0023] like figure 1 , 2, the micro axial flow fan with C-spline curved blades of the present invention includes a motor 1, a hub 2, and a C-spline curved blade 3.

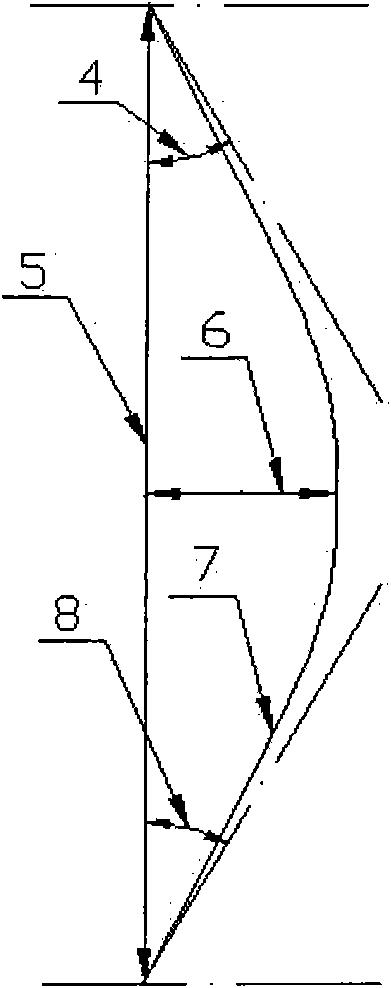

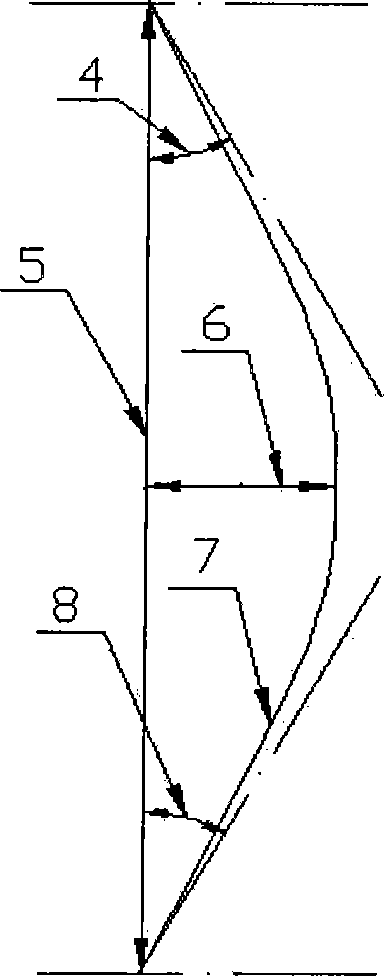

[0024] The C-spline curved blades 3 are installed on the hub 2 at equal intervals. The hub 2 is connected to the motor 1 through the rotating shaft. The curved line 7 of the C-spline curved blade 3 is formed by smooth connection of two C-spline curves. And it satisfies the following mathematical analytic relations:

[0025] x = 3 tan α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com