A radial curved blade centrifugal pump impeller

A centrifugal pump impeller and blade technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of no improvement in hydraulic performance, achieve the effects of improving pump performance, improving work efficiency, and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

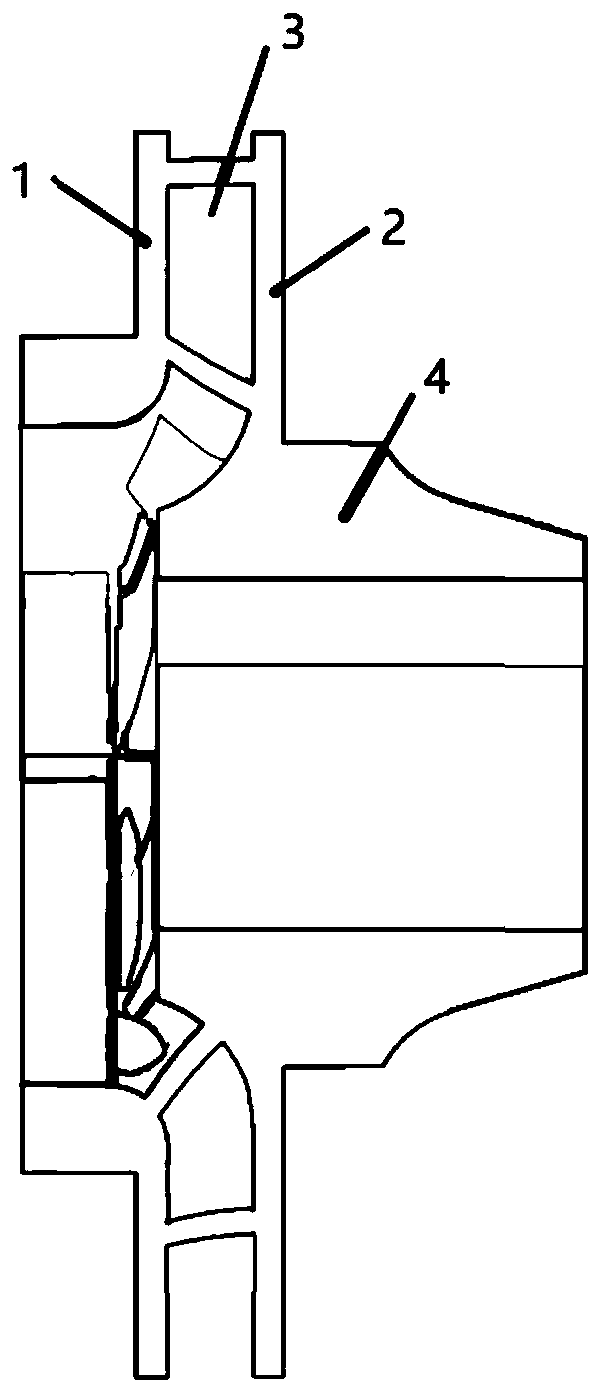

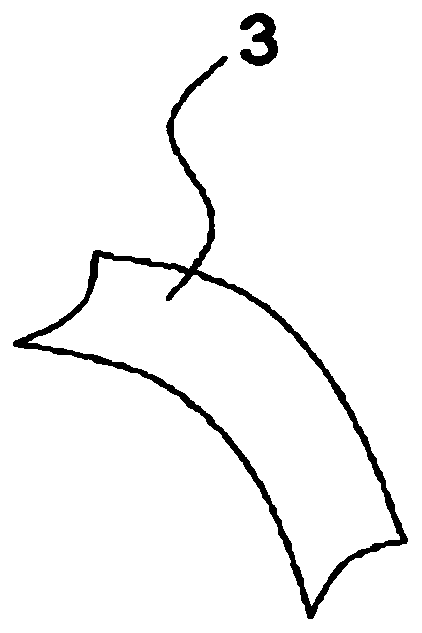

[0024] The radial curved blade centrifugal pump impeller includes a front cover plate 1, a rear cover plate 2, blades 3 and a hub 4, the hub 4 is connected to the pump shaft, the blades 3 are evenly distributed on the hub 4, and the The blade 3 is a curved surface structure that is concave or convex from both sides along its width direction, and the intersection line between the blade 3 and its cross-section in the width direction is C-shaped.

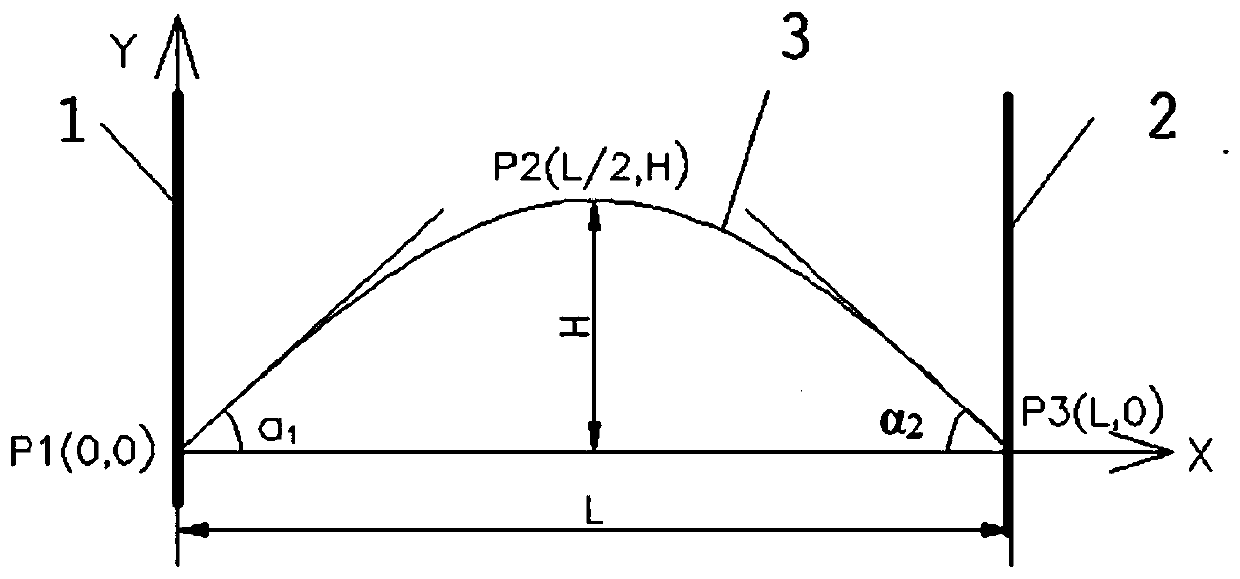

[0025] The intersection points of the C-shaped intersection lines on the plane where the front cover 1 and the rear cover 2 are located are respectively P 1 and P 3 , the intersection points of the C-shaped intersection lines on the plane where the front cover 1 and the rear cover 2 are located are respectively P 1 and P 3 , the highest point of the C-shaped intersection line is P 2 , P on the C-shaped intersection line 1 The tangent at and P 1 P 3 Angle α between connecting lines 1 Satisfy 0°﹤α 1 3 The tangent at and P 1 P 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com