Transformer core vertical tilter

A vertical inversion, transformer technology, applied in the field of transformer manufacturing, can solve the problems of affecting work efficiency, unstable inversion table, huge system, etc., to achieve the effect of improving work efficiency, stable inversion process, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

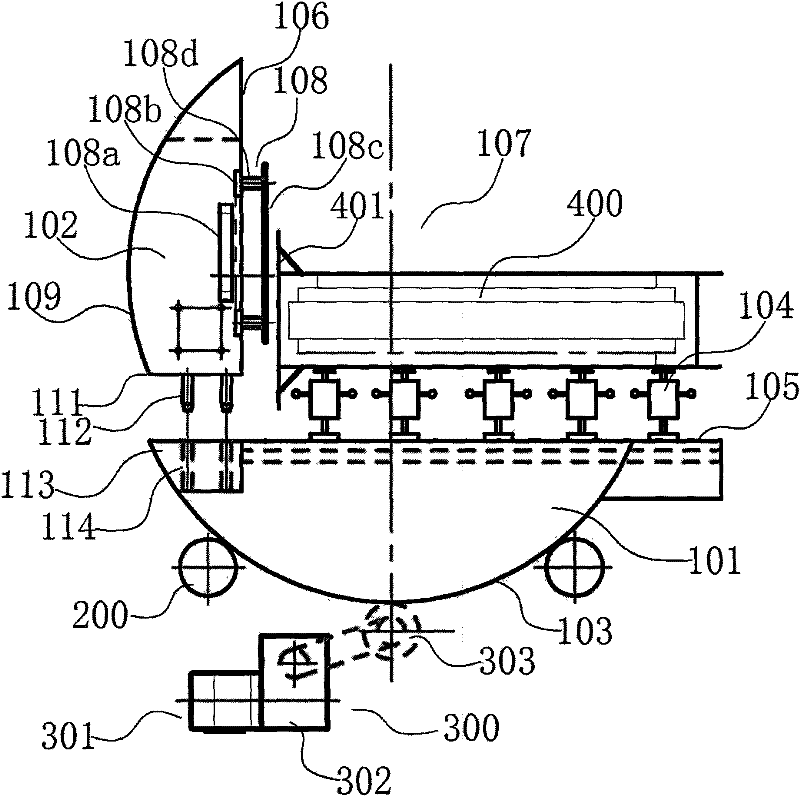

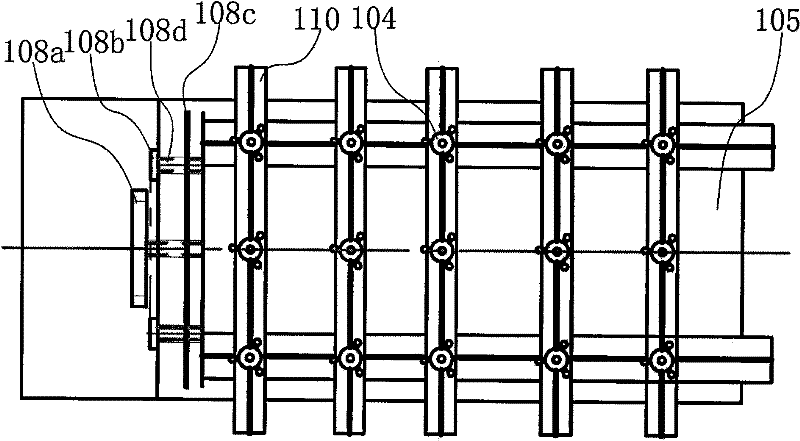

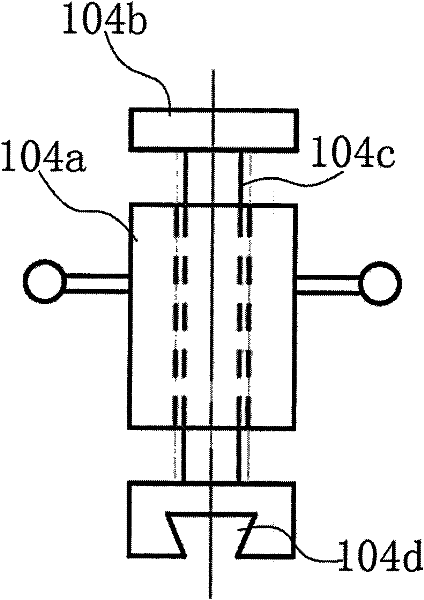

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0032] For the stacking and turning of the transformer core, the traditional method is to use manual stacking and turning over by driving. There are many problems in this method (as described in the background technology section) and it is no longer suitable for the needs of modern industrial production. Therefore, it is urgent to design a A new type of turning device.

[0033] Since the iron core weight of small and medium-sized transformers is less than 15 tons, and the weight of large iron cores is more than 40 tons, the key point of the turning device is to solve the overall stable turning of the iron cores after stacking.

[0034] Based on the above purpose, the transformer core vertical turning machine provided by the present invention uti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com