Motor with parallel structure

A technology of electric motors and coils, applied in the field of electric motors, can solve problems such as large magnetic gaps that have not been resolved, and achieve the effects of improving electrical efficiency, reducing magnetic gaps, and increasing torque and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

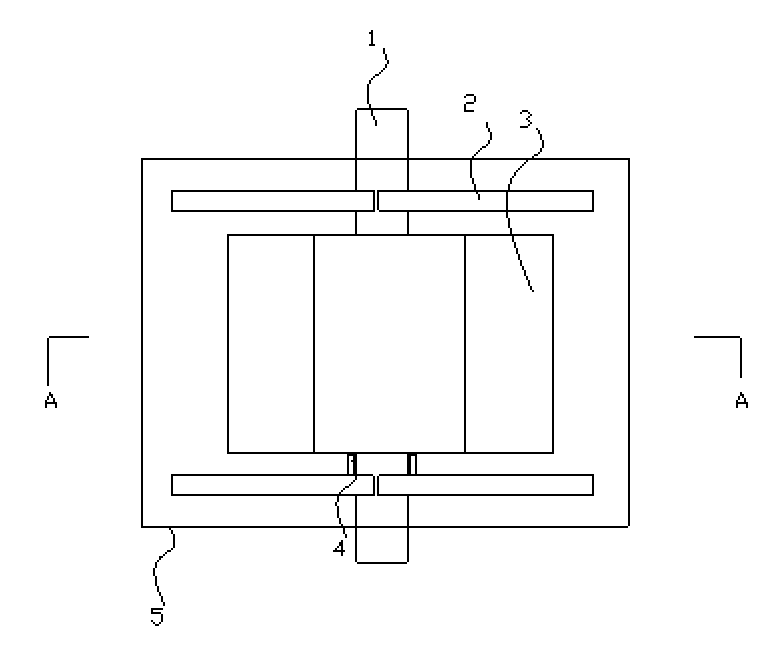

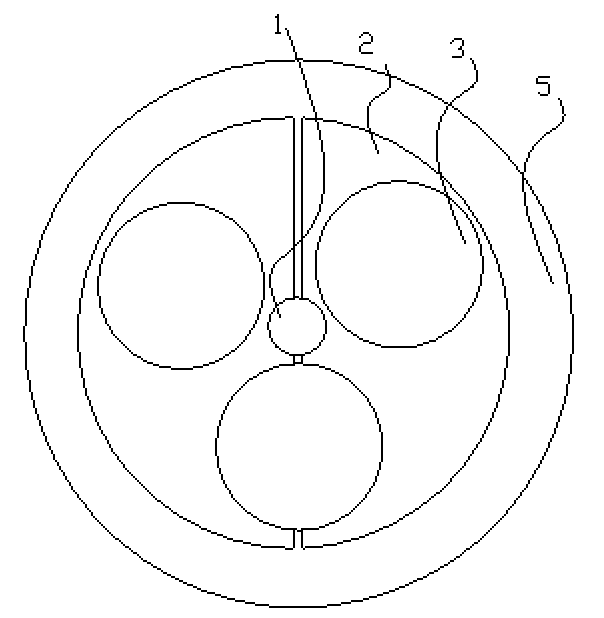

[0019] The electric motor of the parallel structure of present embodiment, see figure 1 , figure 2 ; Including rotor 1, permanent magnet 2, coil 3, carbon brush 4, shell 5. Three coils 3 are evenly distributed around the rotor 1 in a triangular shape. The coil 3 is fixedly connected with the rotor 1 and rotates together with the rotor 1 . The three coils 3 are connected in parallel to the battery through carbon brushes 4 . Two sets of permanent magnets 2 are installed at both ends of the coil 3 , the upper end is N, the lower end is S, and the magnetic field lines pass through the coil 3 . Two groups of permanent magnets 2 are fixedly connected with the shell 5 .

Embodiment 2

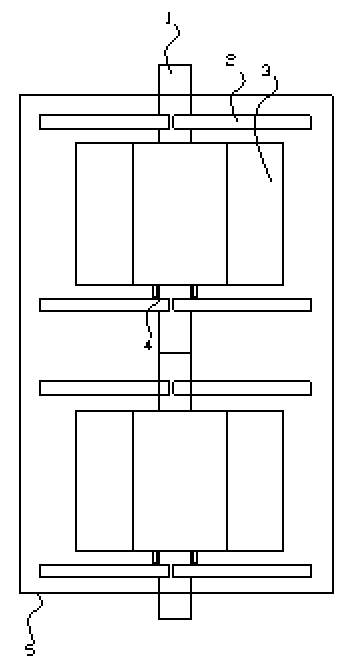

[0021] The electric motor of the parallel structure of present embodiment, see image 3 In the axial direction of the rotor 1, two sets of three coils 3 and two sets of two pairs of permanent magnets 2 can be stacked together. When the installation space is narrow and long, such a structure can obtain a relatively large torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com