Excess sludge reduction bioreactor with variable aeration and worm attachment oblique plate

A bioreactor, excess sludge technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of poor sludge reduction effect, etc., can achieve the effect of improving sludge reduction effect, improving working capacity and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

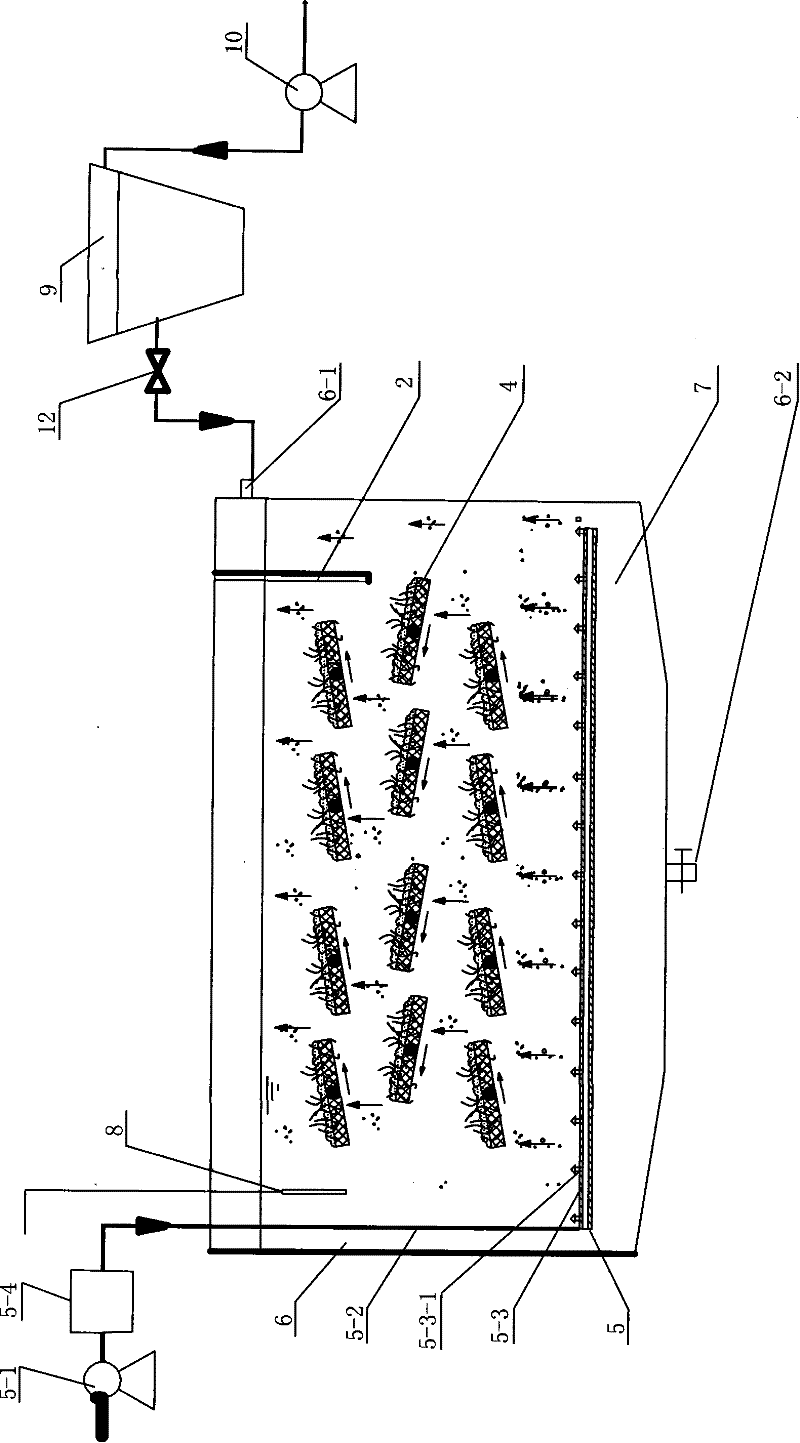

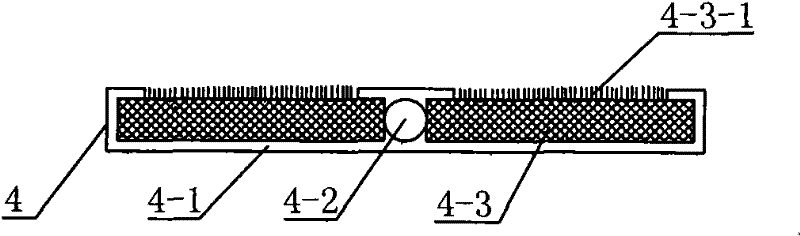

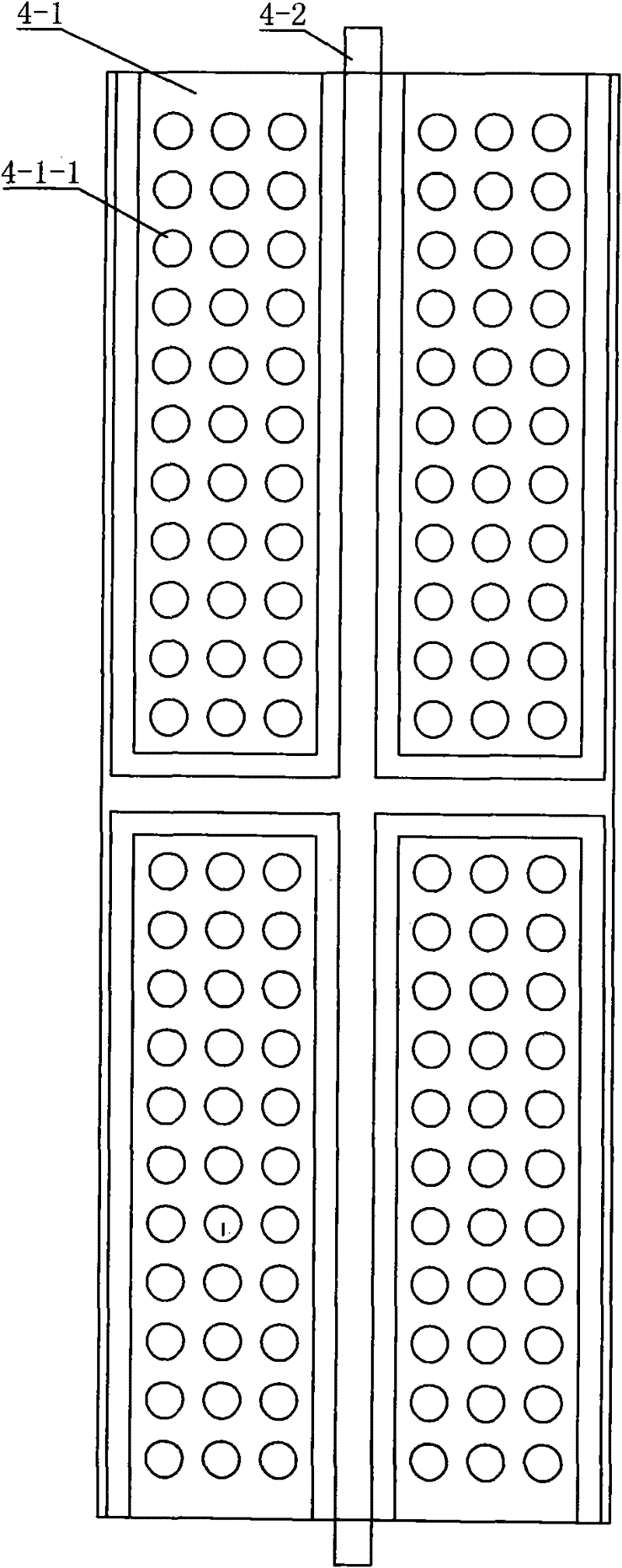

[0017] Specific implementation mode one: the following combination Figure 1 to Figure 3 Specifically illustrate this embodiment, the residual sludge reduction bioreactor with variable aeration and worm attachment sloping plate described in this embodiment includes a container 6, a mud bucket 7 and a baffle 2; the bioreactor also includes A plurality of worms are attached to the inclined plate 4 and the variable aeration device 5; the mud bucket 7 is positioned at the bottom of the container 6 and the two are connected as one, the upper end of the side wall of the container 6 has an inlet 6-1, and the bottom of the mud bucket 7 has a The outlet 6-2, the baffle plate 2 is arranged in front of the entrance 6-1 in the container 6, and a plurality of worm attachment sloping plates 4 are layered and staggered evenly arranged inside the container 6 along the height direction, and each worm attachment slanting plate 4 is made of filler plate 4-1, fixed shaft 4-2 and packing layer 4-3...

specific Embodiment approach 2

[0019] Specific implementation mode two: the following combination Figure 1 to Figure 3 This embodiment is specifically described. The thickness of the filler layer 4-3 in this embodiment is 1.0-1.2 cm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: the following combination Figure 1 to Figure 3Describe this embodiment in detail. The packing layer 4-3 in this embodiment is made of polyethylene material. There are a large number of holes or gaps with a diameter or width of 2-3 mm evenly distributed on the packing layer 4-3. The large number of holes or The slits criss-cross and communicate up and down, that is, the packing layer 4-3 is a net-like porous packing layer for carrying worms; benthic worms are used as sludge predators, and they are inoculated and fixed in porous worms according to their physiological characteristics. Sexual filler 3 inside. This porous packing 3 has simulated the natural living environment of worms-bottom mud (filling layer 4-3 is similar to the natural living environment of worms), adapts to the drilling characteristics of worms, and worms can freely move in the porous packing Crawl and drill holes. This kind of porous filler can also help the worms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com