Device for distributing double-sided adhesive tape on frame strip

A double-sided adhesive tape and frame strip technology, which is applied to the installation of sealing devices and window glass, can solve the problems of poor control of manual rolling pressure, affecting product quality stability, uneven rolling pressure, etc., and shortens the operation. cycle, improved accuracy and stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

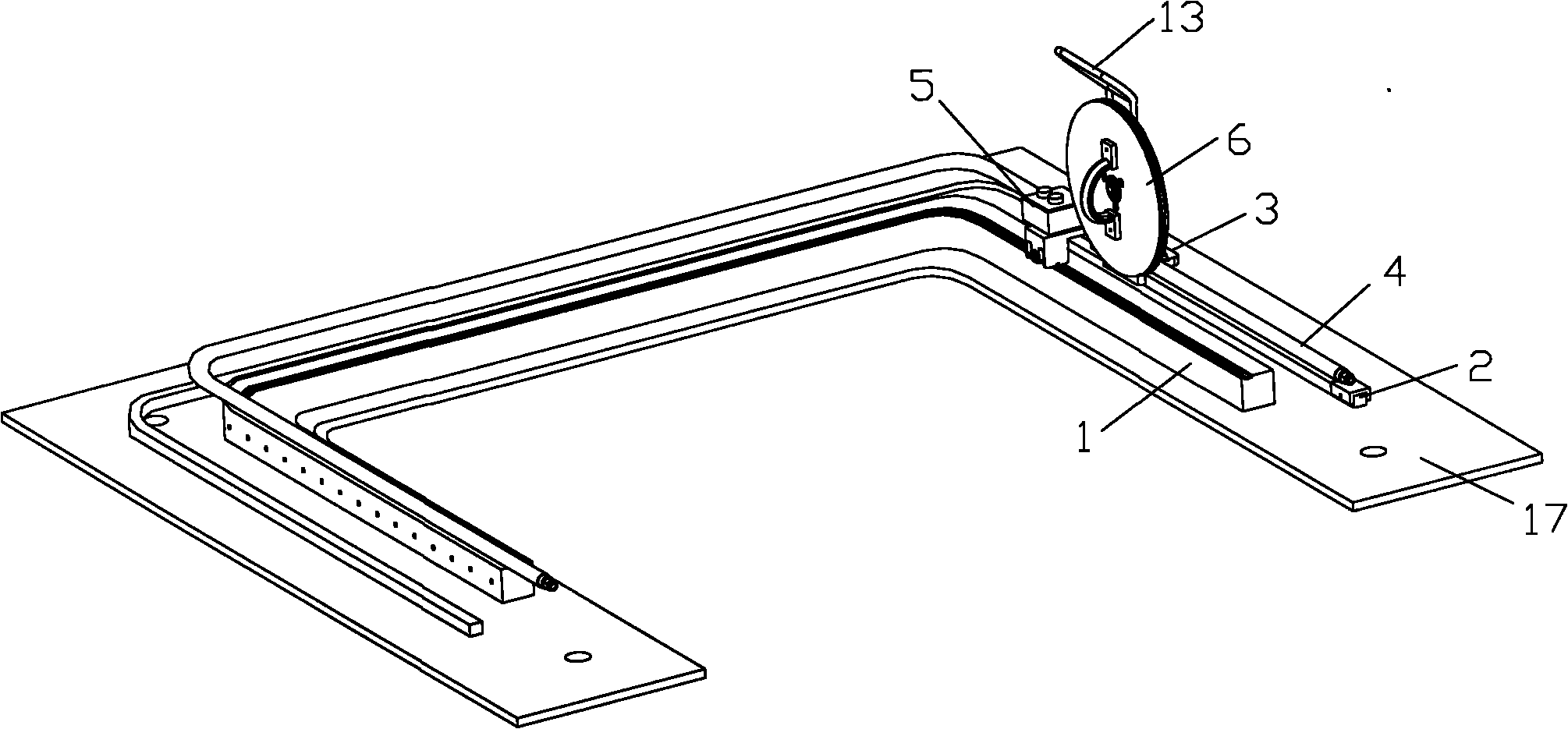

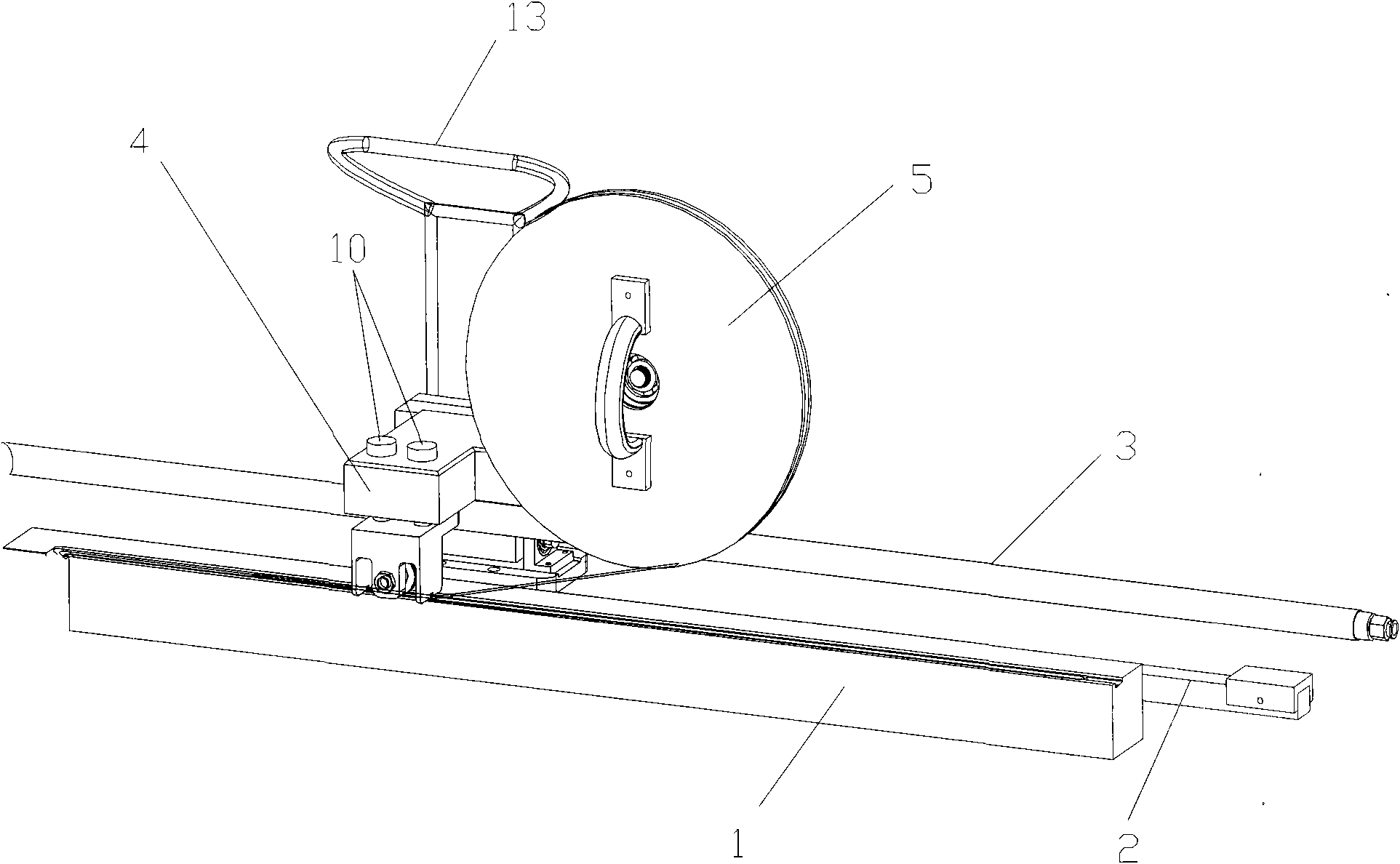

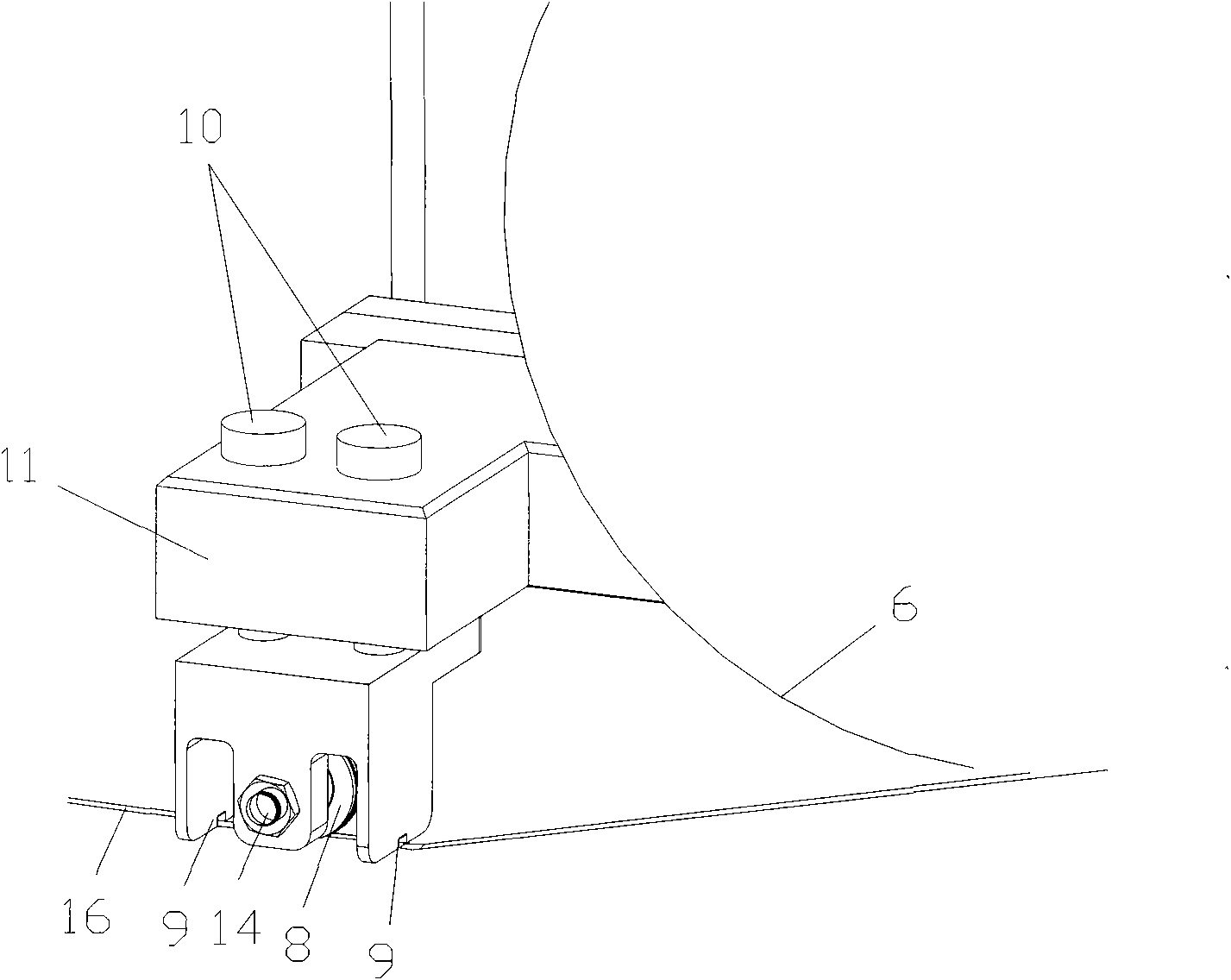

[0016] The structure of the present invention includes a positioning groove 1 with a vacuum suction hole, a frame work surface 17 for fixing the positioning groove, and is characterized in that it also includes a guide rail 2, a guide roller support seat 3, a rubber cloth rolling trolley 5, a double Surface tape fixing plate 6; the shape of the positioning groove frame is designed according to the shape of the frame strip, which is a straight groove frame, or an arc groove frame with any radian, or a combination of a straight groove frame and an arc groove frame with a smooth transition Slot frame; the guide rail 2 is located on the outside of the positioning groove 1, and is also fixed on the work surface 17. Its geometric shape and plane position correspond to the geometric shape and plane position of the positioning groove 1. The cross-sectional shape of the guide rail 2 is a protruding triangle on both sides. There are two symmetrical round holes on the guide roller support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com