Primary-secondary type gas sensor

A gas sensor, mother-in-law technology, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of data uploading function, loss of practical significance, and information cannot be shared, etc., to meet the key points and comprehensive monitoring, The effect of improving reliability and reducing blind spots in monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

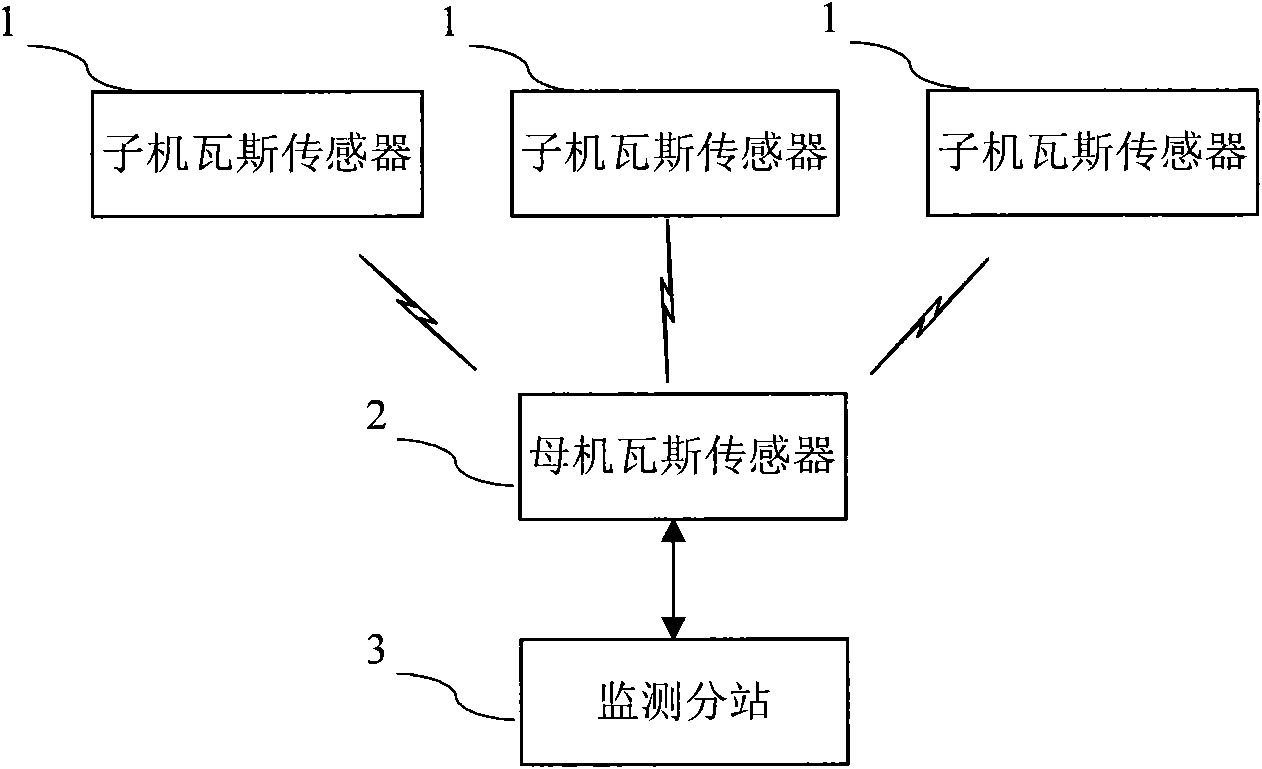

[0030] figure 1 Shows the structure of the mother-child gas sensor of the present invention, including: a plurality of slave machine gas sensors 1, used to respectively detect the slave machine gas concentration; a master machine gas sensor 2, used to detect the master machine gas concentration, and through the connection line to monitor The substation 3 uploads the gas concentration signal and receives the gas concentration signal transmitted from the monitoring substation 3; among them, the gas sensor 1 of the slave machine communicates with the gas sensor 2 of the master machine wirelessly, and the gas concentration signal detected by the gas sensor 1 of the slave machine is wirelessly communicated. Send it to the gas sensor 1 of the parent machine, and then send it to the monitoring substation 3 by the gas sensor 2 of the parent machine via the signal line.

[0031] The gas sensor 2 of the master machine of the present invention is connected with the monitoring substation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com