Imprint wiring porous plate printing device

A technology for printing devices and wiring holes, which is applied in the field of embossing stencil printing devices, and can solve the problems that wiring and overprinting cannot be performed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

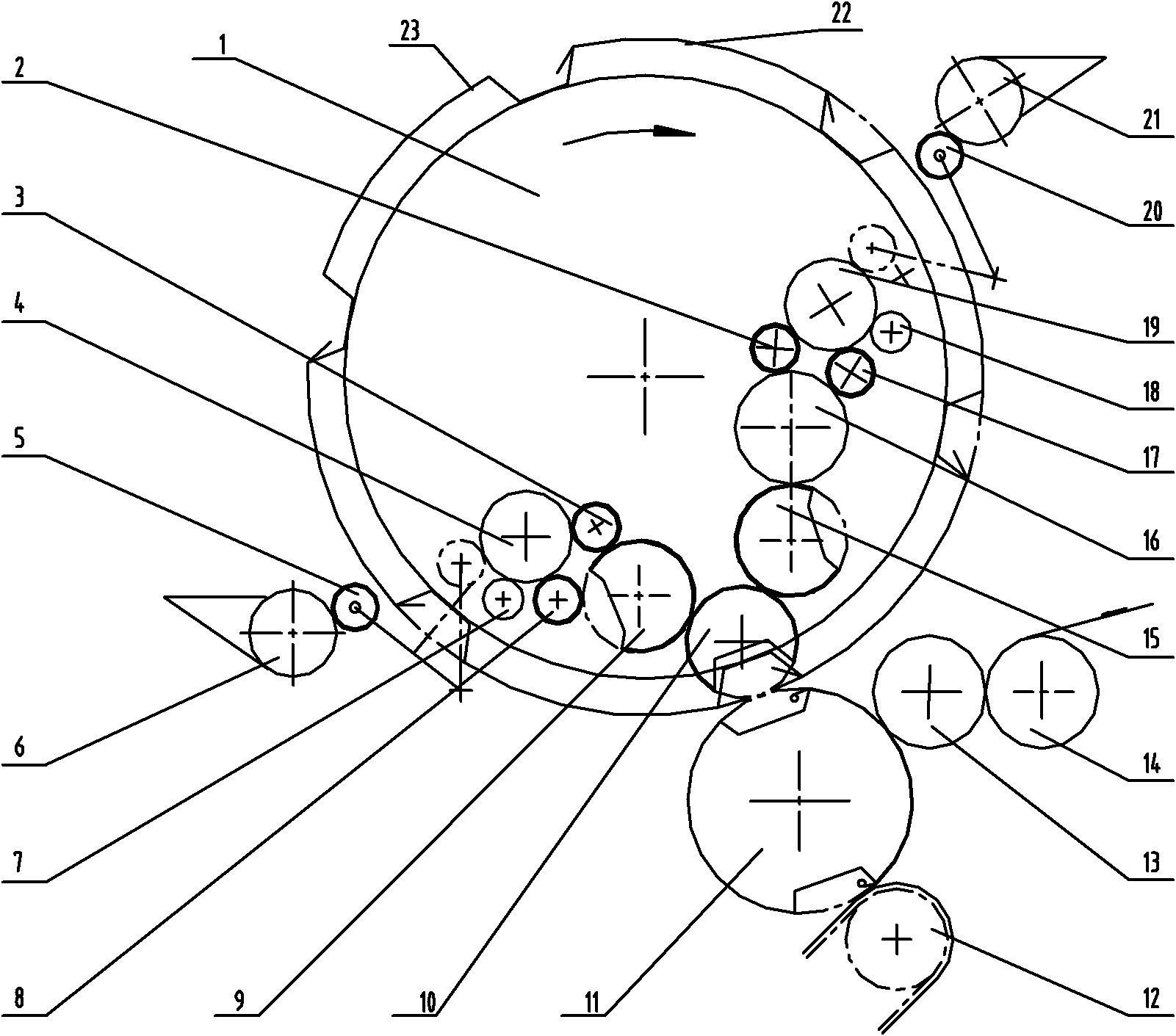

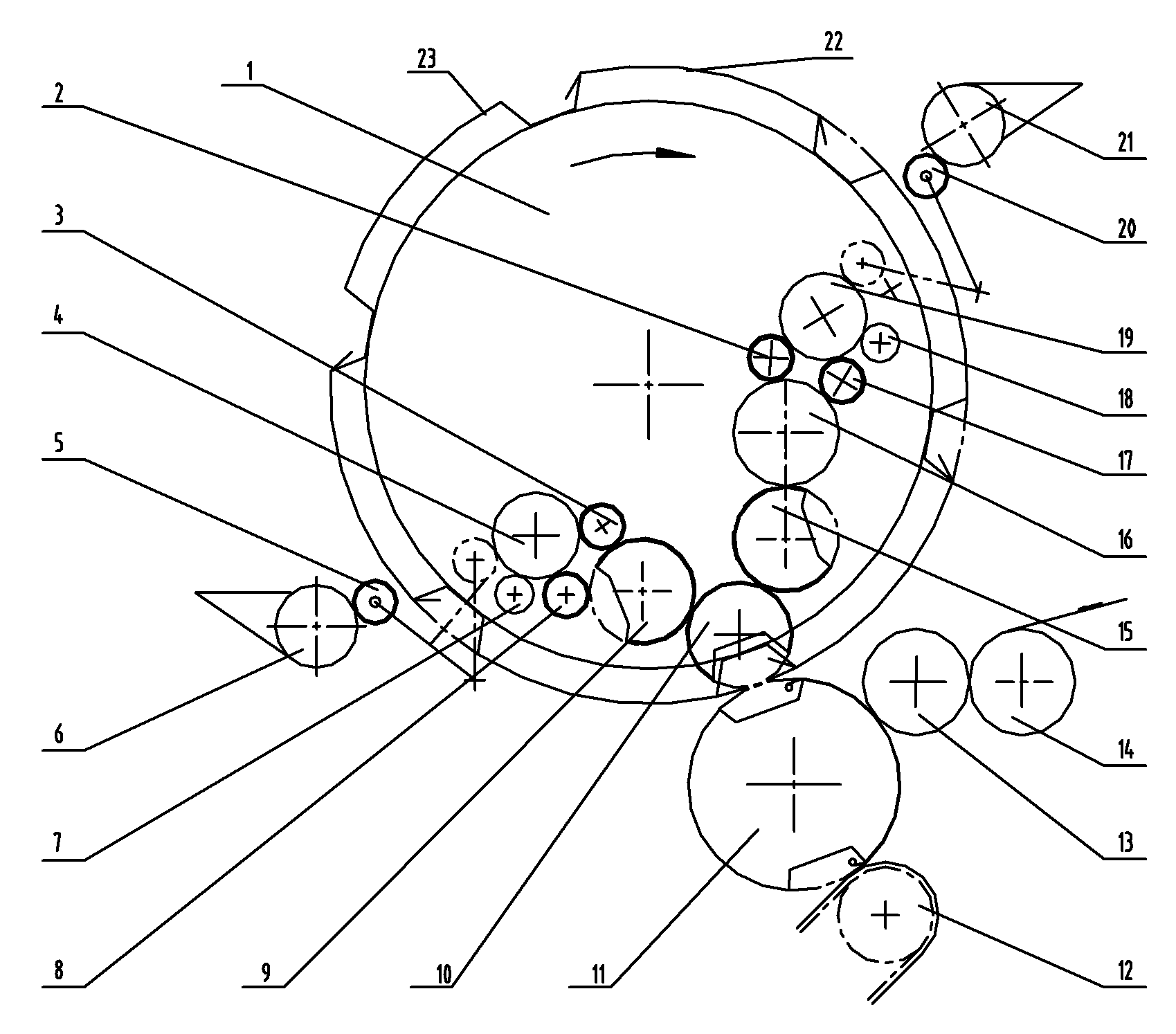

[0013] Such as figure 1 As shown, an embossing type wiring stencil printing device mainly includes a stencil cylinder 1, an embossing cylinder 11, a color collecting cylinder 10, color mold rollers 9 and 15, and an ink transfer system. The following details each part: This embodiment The ink transfer system in the system is composed of two sets of ink transfer systems on the left and right sides of the color collecting cylinder 10. On the left side of the color collecting cylinder 10, the left swinging ink transfer roller 5 swings between the left ink fountain roller 6 and the left ink transfer roller 4 to transfer the ink From the left ink fountain roller 6 to the left ink transfer cylinder 5, the left ink transfer cylinder 5 transfers the ink to the left color mold roller 9 through the two adjacent form rollers 3 and 8, and the left color mold roller 9 In contact with the color collecting cylinder 10 and transfer the ink to the color collecting cylinder 10, there is a string...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com