Dot matrix code anti-fake printing machine

A printing machine, dot matrix code technology, applied in printing, typewriter, printing device and other directions, can solve the problems of high consumption, high requirements on ink varieties, increase production cost, etc., to strengthen detection, improve the adjustable range of inkjet , The effect of preventing no ink and excessive ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

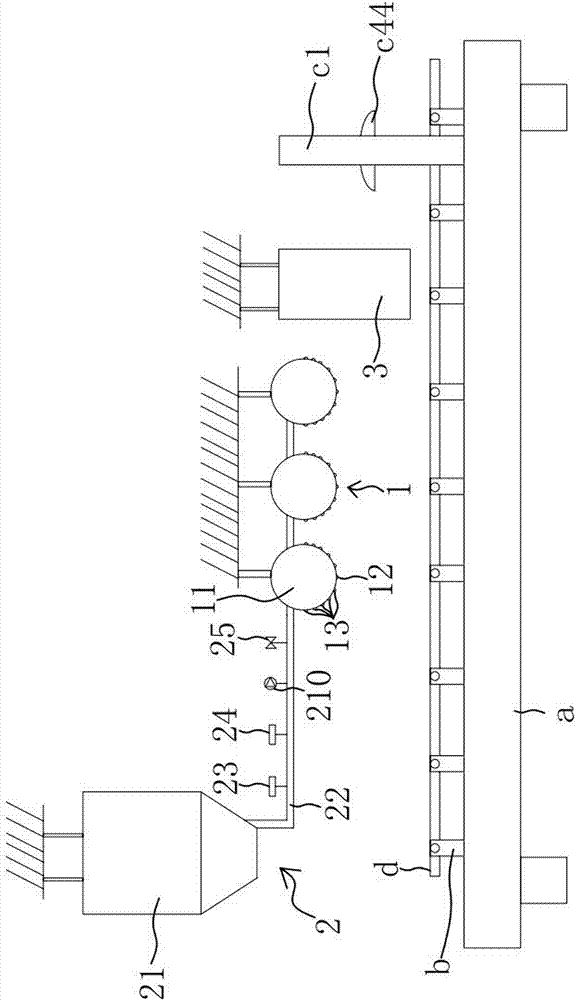

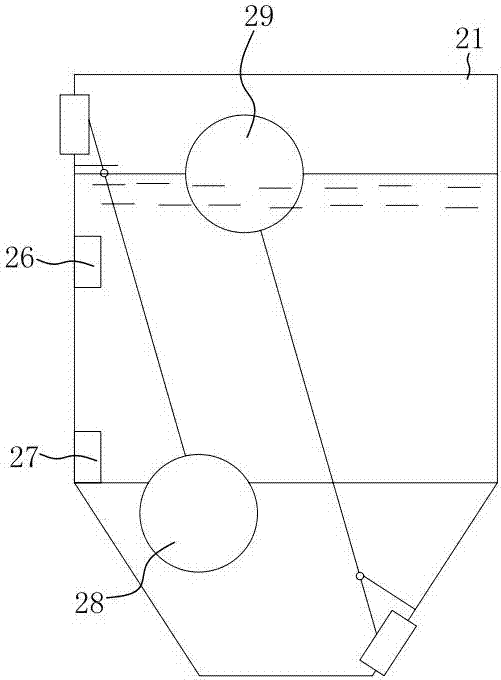

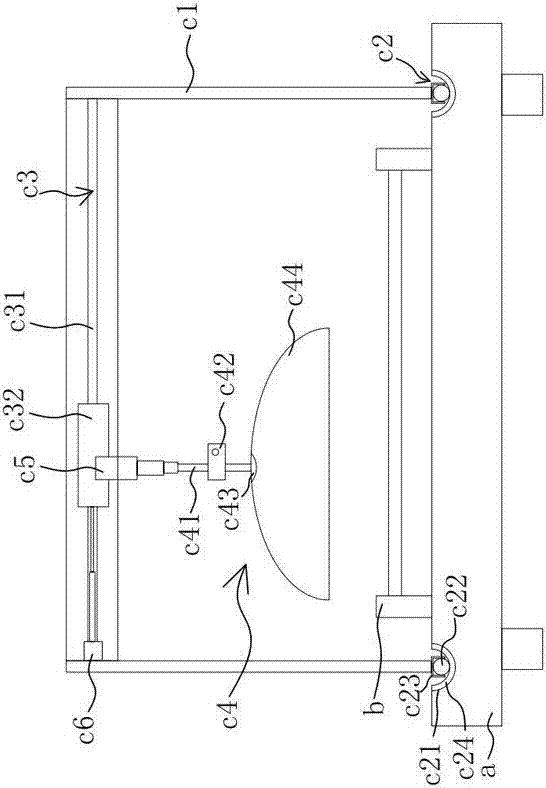

[0024] Such as Figures 1 to 4 As shown, the dot matrix code anti-counterfeiting printing machine includes a transmission frame b arranged on the carrier platform a, and a conveyor belt d carrying items to be printed is arranged on the transmission frame b, and is characterized in that: a spray nozzle is suspended above the conveyor belt d. Code assembly 1, the inkjet code assembly 1 is connected with the ink storage assembly 2, near the front side of the inkjet code assembly 1 along the conveying direction of the conveyor belt d is provided with an infrared dryer 3 above the conveyor belt d, and the end of the conveyor belt d is provided with a A finished product inspection device for detecting the printing quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com