Micro-structure adhesive tape

A technology of microstructure and adhesive tape, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of increasing the number of light-emitting diodes arranged, poor control of microstructure injection, uneven development of light guide plates, etc., to reduce the development Non-uniformity, easy production, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After understanding the preferred embodiments of the present invention, any person of ordinary skill in the art can make changes and modifications based on the technology disclosed in the present invention, and without departing from the spirit and scope of the present invention.

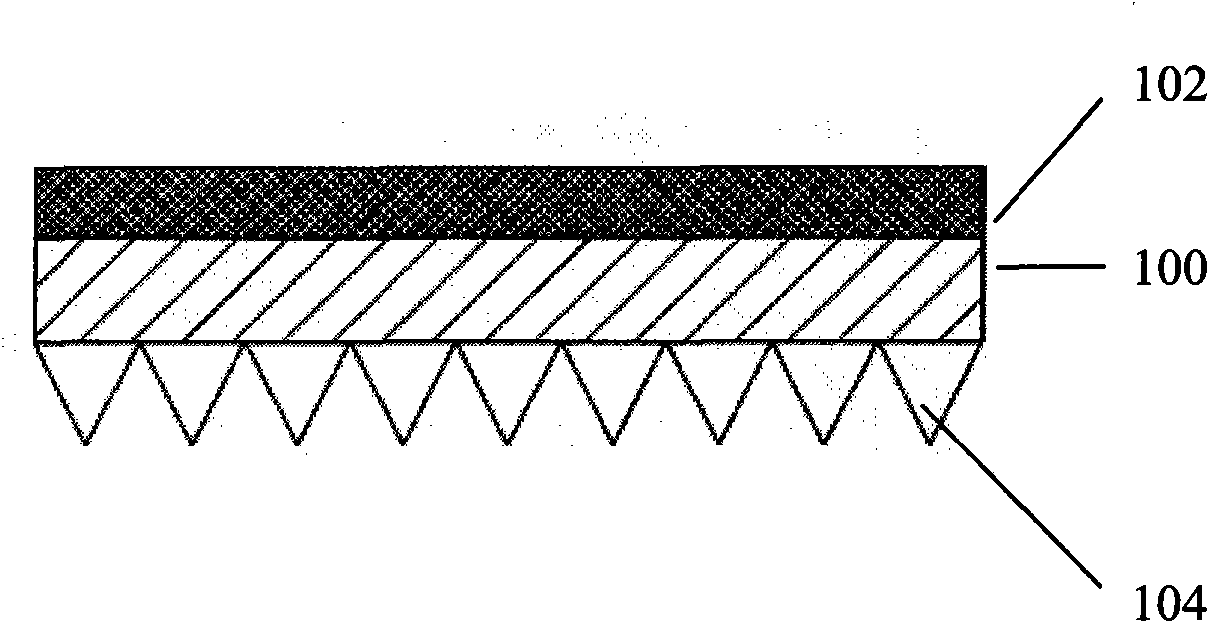

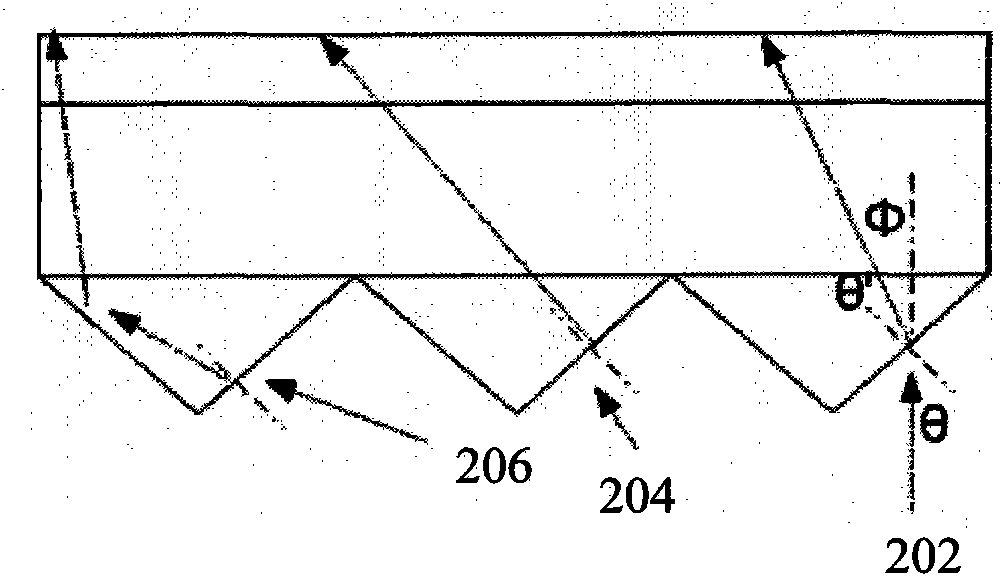

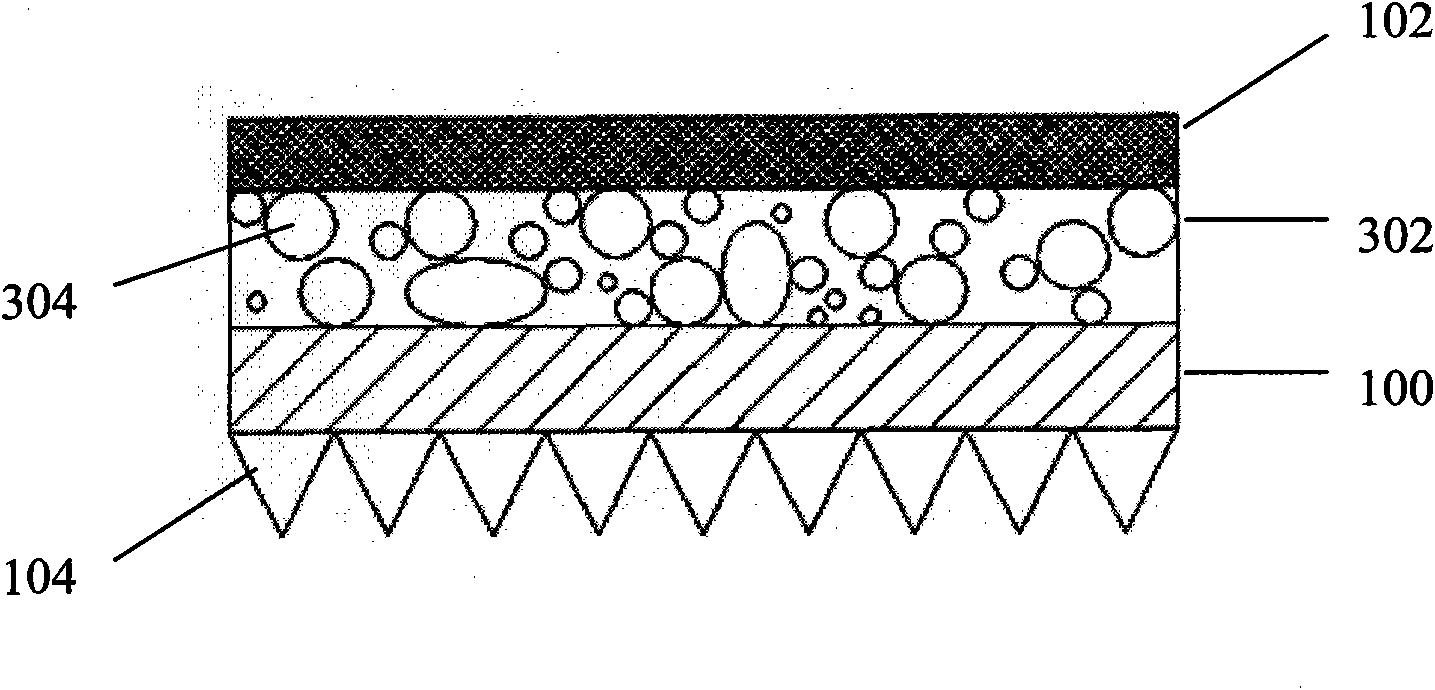

[0035] The invention relates to a microstructure adhesive tape, which comprises: a base material layer and an adhesive layer. There are multiple microstructures on one side of the substrate layer, and the adhesive layer is coated on the other side of the substrate layer. When in use, the adhesive layer of the adhesive tape is adhered to the side of the light guide plate to reduce the phenomenon of uneven development.

[0036] refer to figure 1 , which is a cross-sectional view illustrating an embodiment of the microstructure adhesive tape of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com