Screw locking machine

A technology for locking screw machines and screw barrels, which is applied to screwdrivers, motor tools, wrenches, etc., which can solve problems such as fatigue operation, low efficiency, and increased labor intensity of operators, and achieve convenient operation, improve work efficiency, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

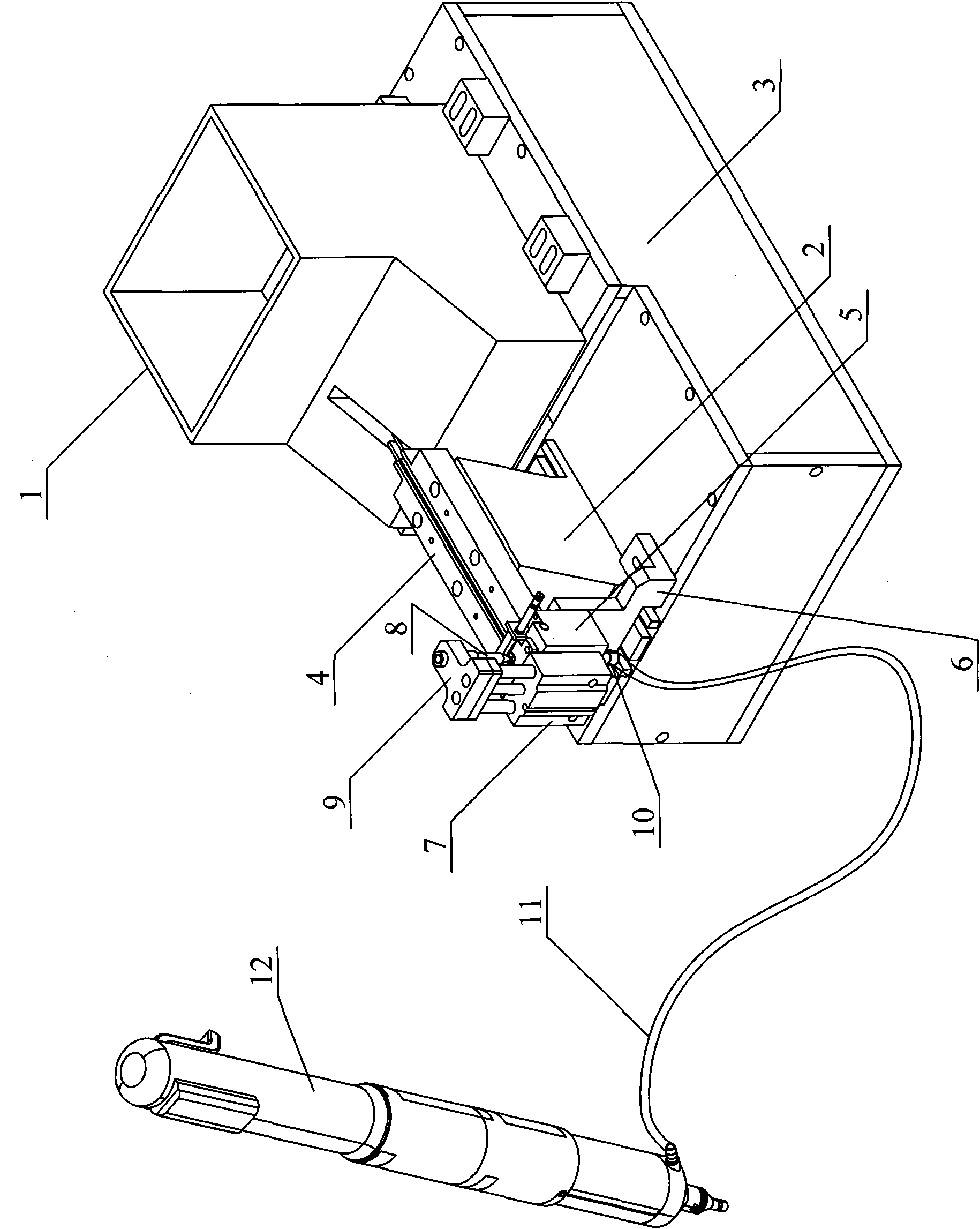

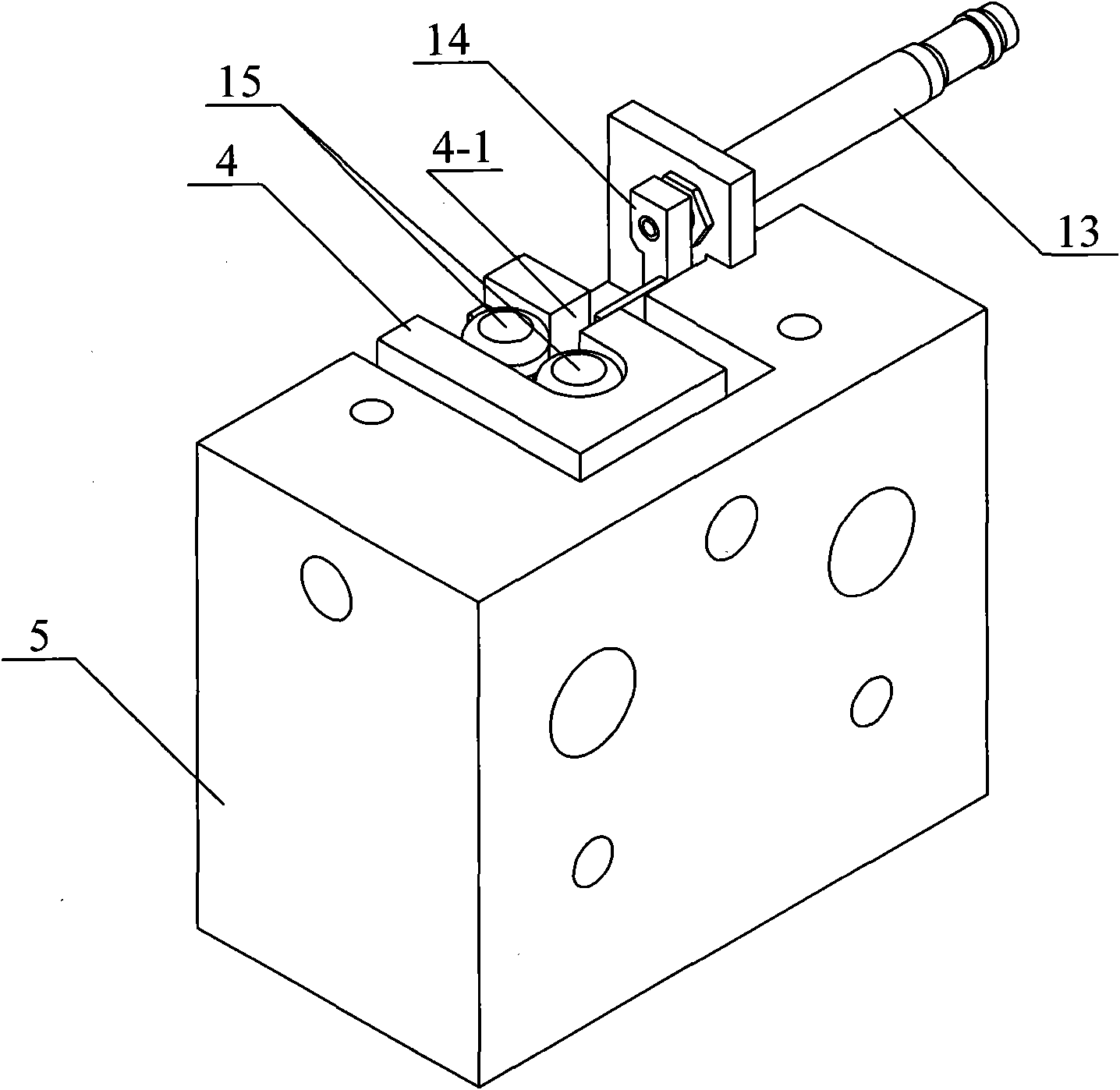

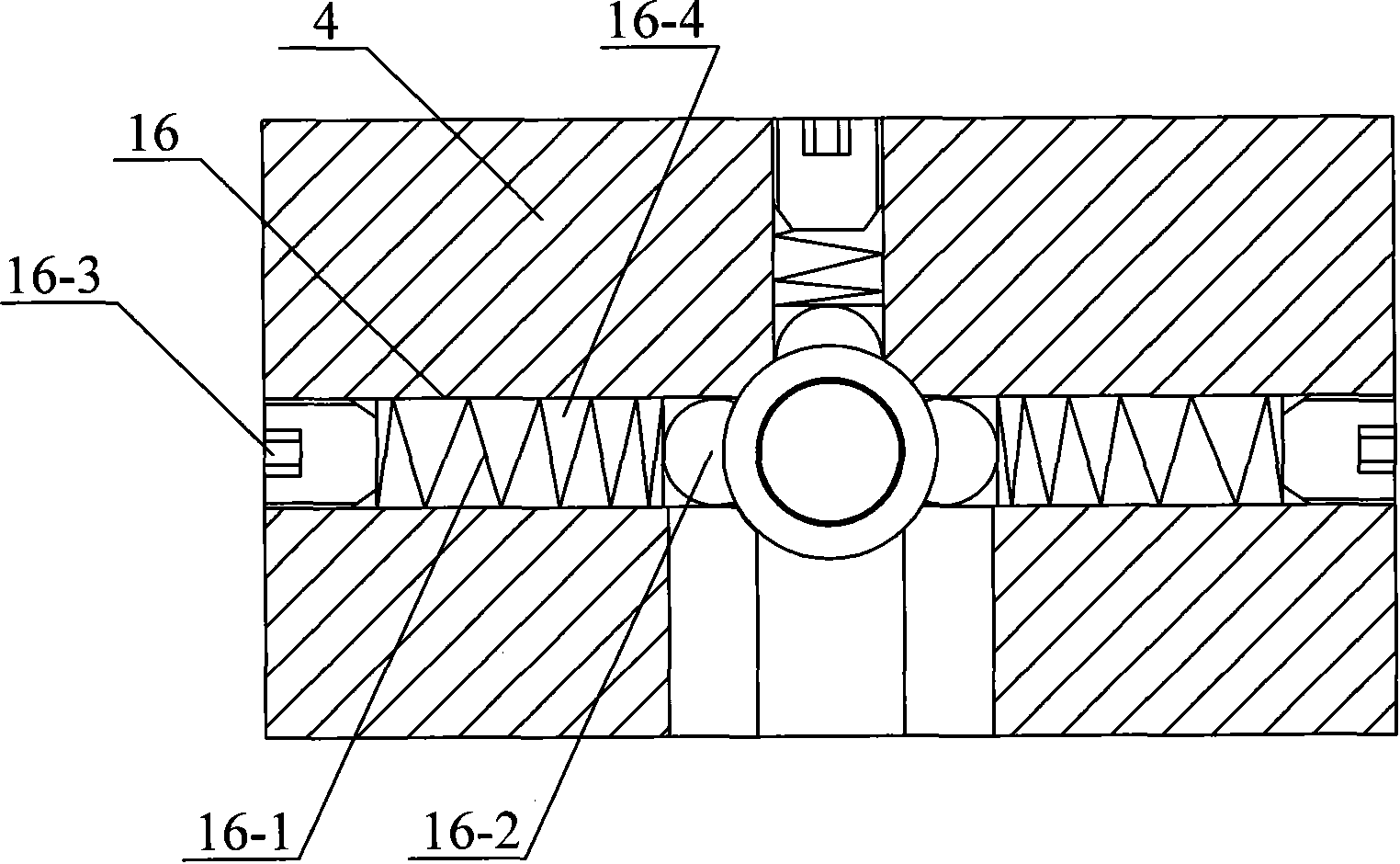

[0023] like figure 1 As shown, the screw locking machine in this embodiment includes a vibrating feeder 1, a linear vibrator 2, a main body electric control box 3, a material channel 4, a distribution block 5, a support block 6, a cylinder 7, an air blowing nozzle 8, a blowing Air nozzle fixing block 9, air guide tube connector 10, air guide tube 11 and locking mechanism 12.

[0024] The above-mentioned vibrating feeder 1 and linear vibrator 2 are connected on the main electric control box 3, and the material channel 4 is connected on the linear vibrator 2, and one end of the material channel 4 is connected with the discharge port of the vibrating feeder 1, and the other One end links to each other with distributing block 5. The distribution block 5 is connected to the electric control box 3 of the main body by means of a support block 6 . The air cylinder 7 is connected to the above-mentioned distribution block 5 , and the front end of the piston rod of the air cylinder 7 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap