Container Weighing Device

A weighing device and container technology, which is applied in the direction of weighing indicating device, measuring device, weighing, etc., can solve the problems of reducing hoisting efficiency, reducing weighing accuracy, time-consuming and labor-intensive, etc., to improve hoisting safety and hoisting The effect of improving efficiency and improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

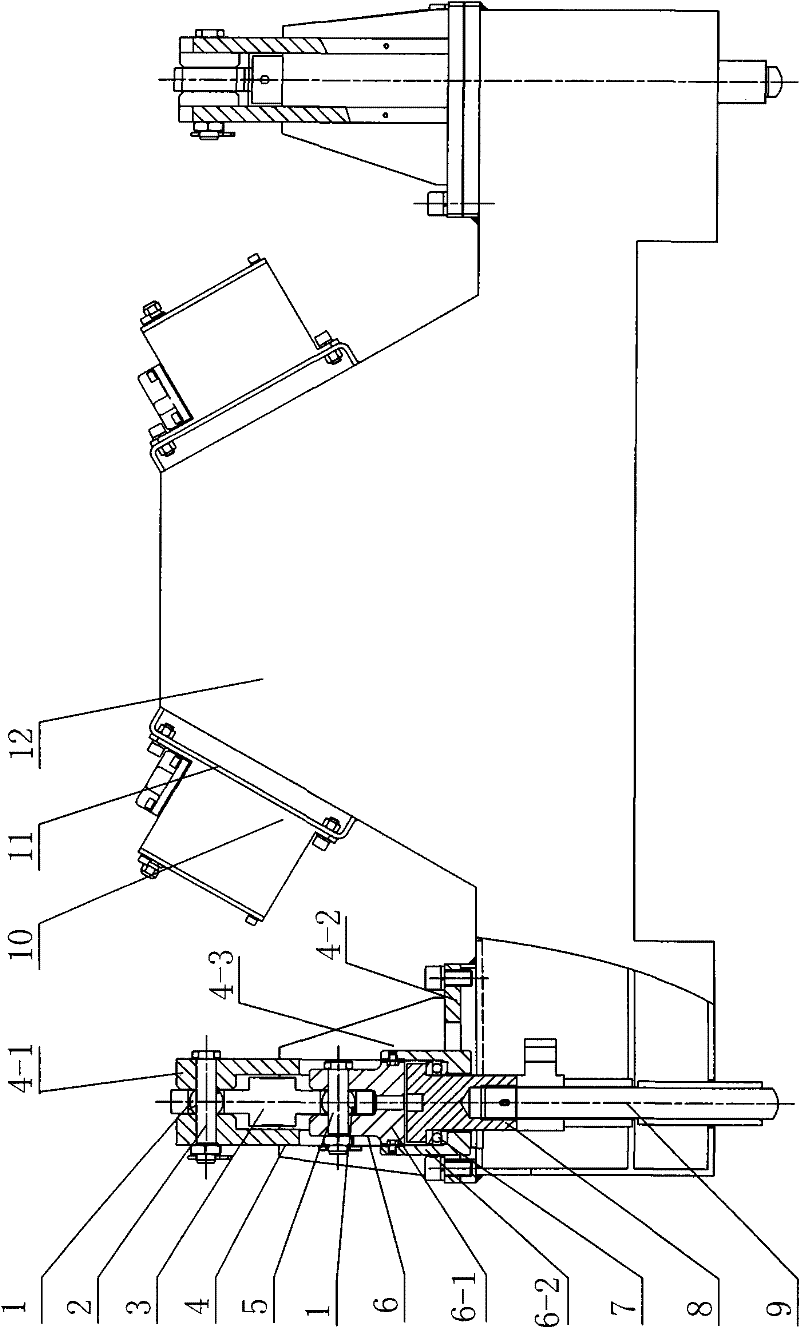

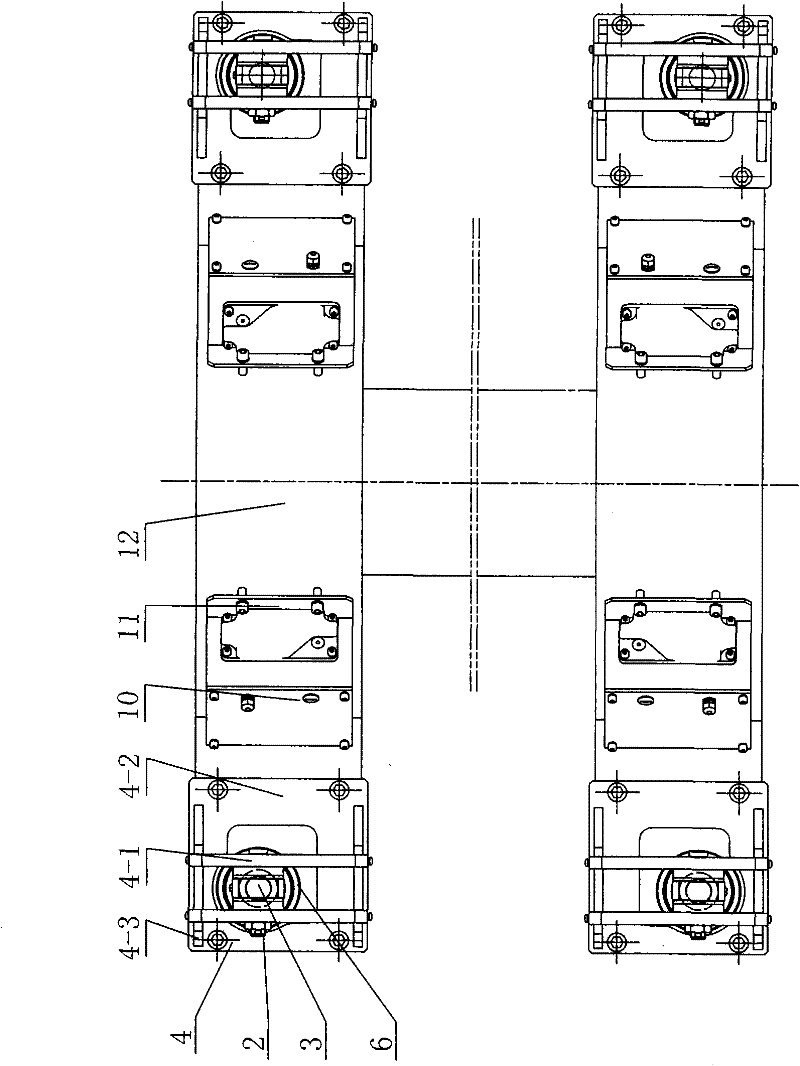

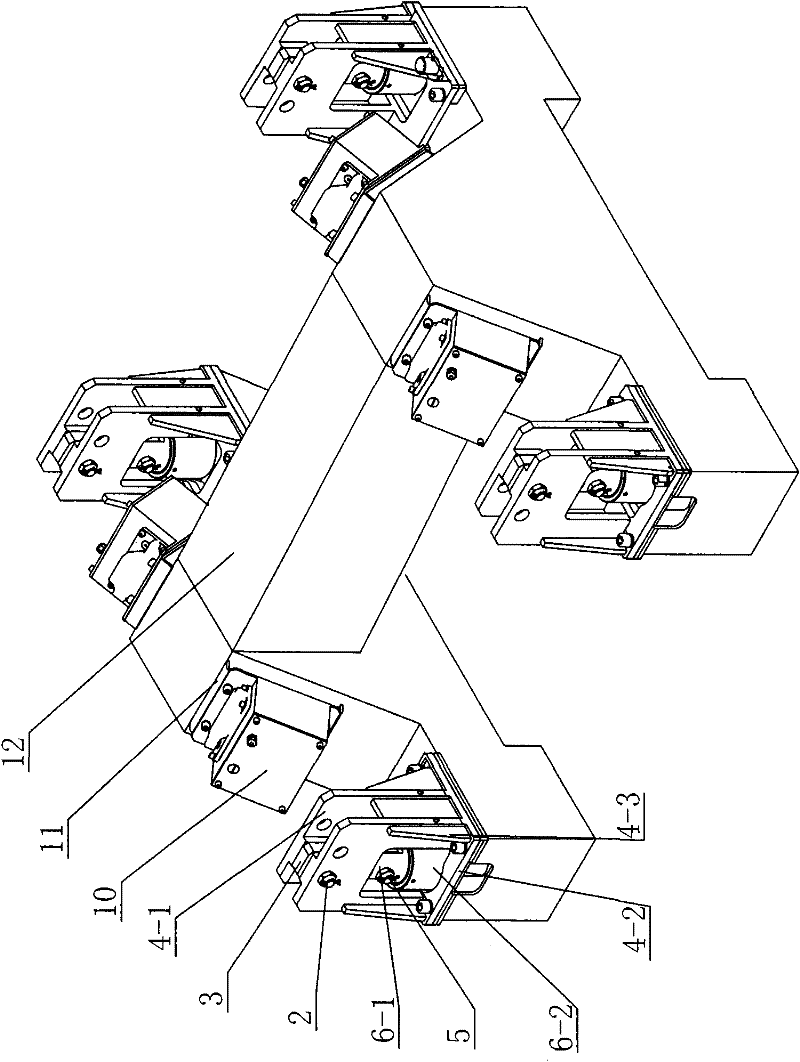

[0011] See Figure 1~3 As shown, the container weighing device of the present invention includes a hanger 12, a support 4, a load cell 3 and a wireless transmitting module 10. The hanger 12 is an I-shaped hanger, and the four corners of the hanger 12 have mounting seats. Each support 4 is installed on each mounting base respectively, and support 4 of the present invention has the supporting arm 4-1 that is integrated with base 4-2, and for improving the intensity of support 4, support 4 is on base 4-2 and support Ribs 4-3 are also fixed on the arm 4-1, the upper part of each load cell 3 is connected with the supporting arm 4-1 through the upper pin shaft 2 and the joint bearing 1, and the lower part of each load cell 3 is connected with the lower pin shaft 5 And the joint bearing 1 is connected with the floating seat 6, see figure 1 As shown, the upper connecting seat on the upper part of the load cell 3 and the lower connecting seat on the lower part are provided with bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com