Ore pulp non-pressure pipeline sampler

A sampler and pulp technology, applied in the field of pipeline pulp sampling device, can solve problems such as poor stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

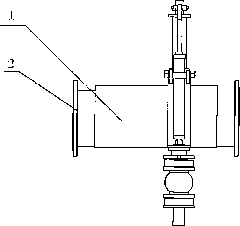

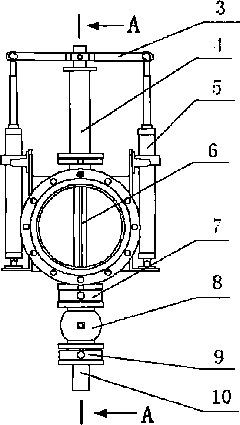

[0016] The ore slurry sampler of pressureless pipeline of the present invention, its preferred embodiment is:

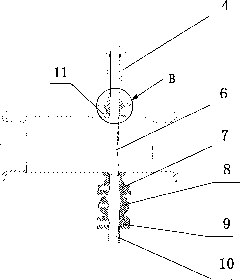

[0017] Including the main box, the upper part of the main box is equipped with a sampling tube sheath, the sampling tube sheath is provided with a sampling tube, the sampling tube passes through the sampling tube sheath, and the sampling tube An actuator is provided between the upper end and the main box, and through holes are respectively provided on the upper wall and the lower wall of the main box opposite to the lower end of the sampling tube;

[0018] The lower part of the main box facing the through hole on the lower wall is sequentially equipped with an upper flushing flange, a control valve, a lower flushing flange, and a sample outlet pipe;

[0019] When the sampling tube is in the upper position, the sampling tube is completely in the sampling tube sheath; when the sampling tube is in the lower position, the lower end of the sampling tube passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com