Filtering, blowing and sweeping control device for waste emulsion treatment system

A treatment system and control equipment technology, applied in filtration and separation, membrane filters, chemical instruments and methods, etc., can solve the problems of difficult waste gas recycling, large harmful waste gas, furnace wall and flue contamination of the atmospheric environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

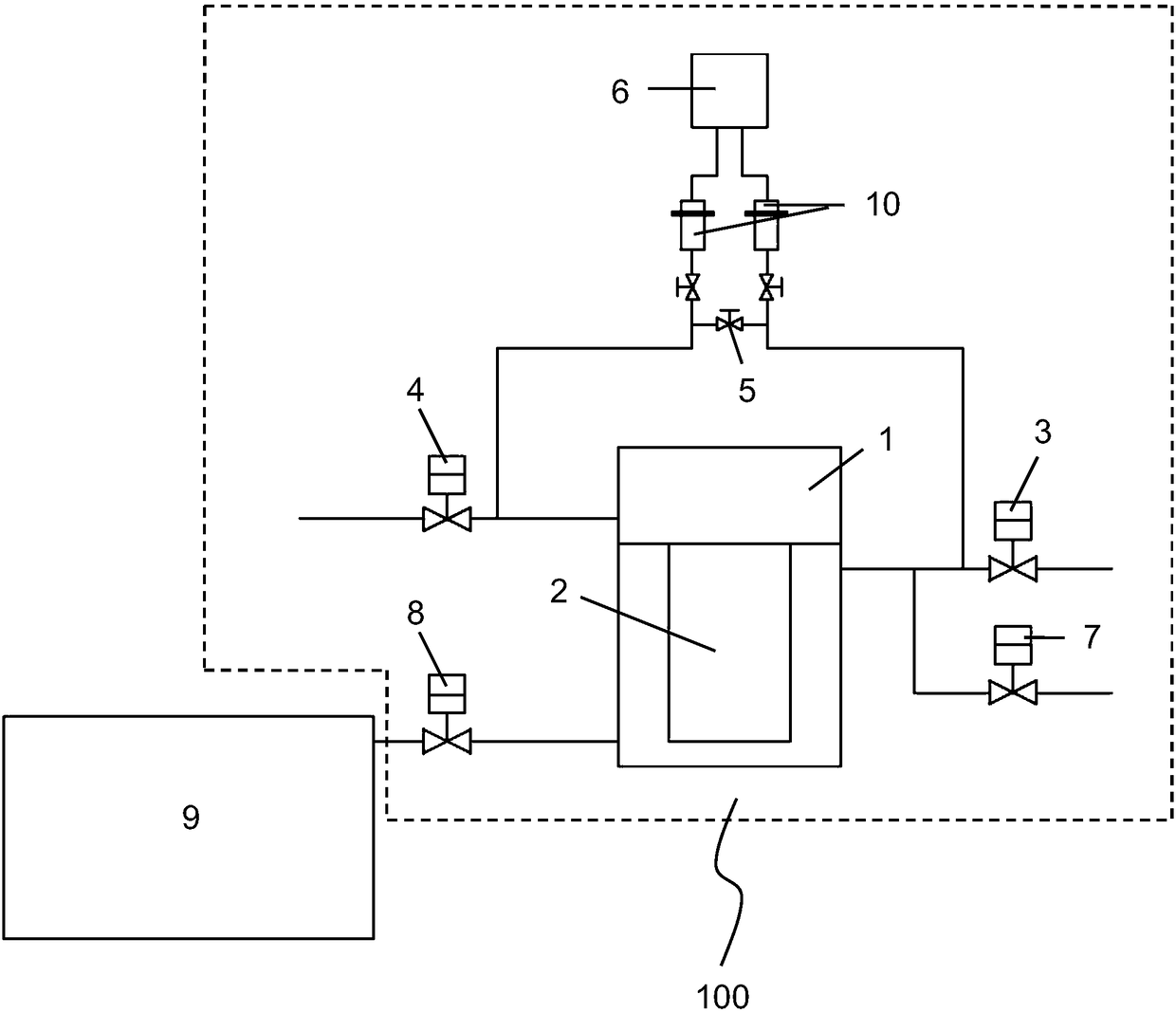

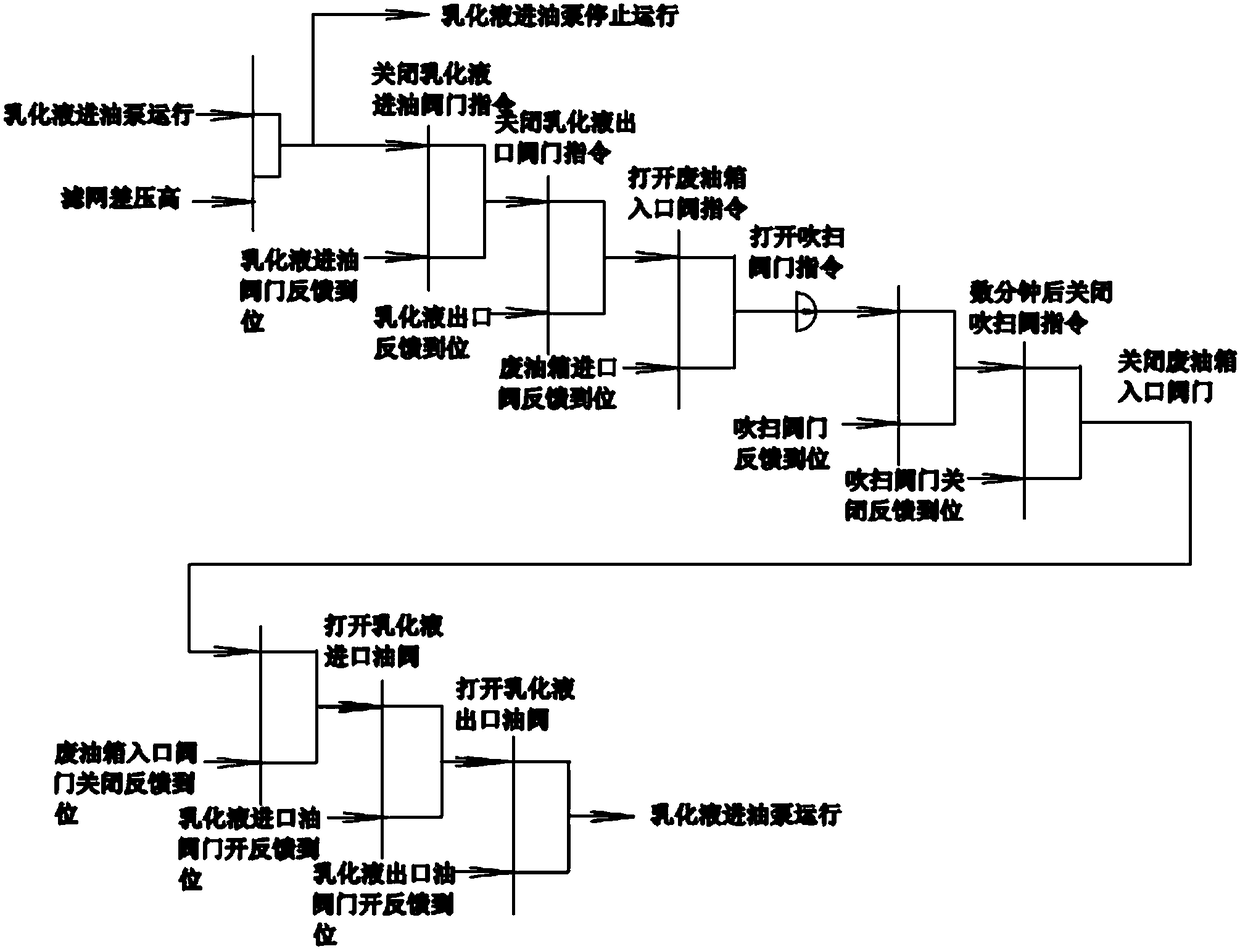

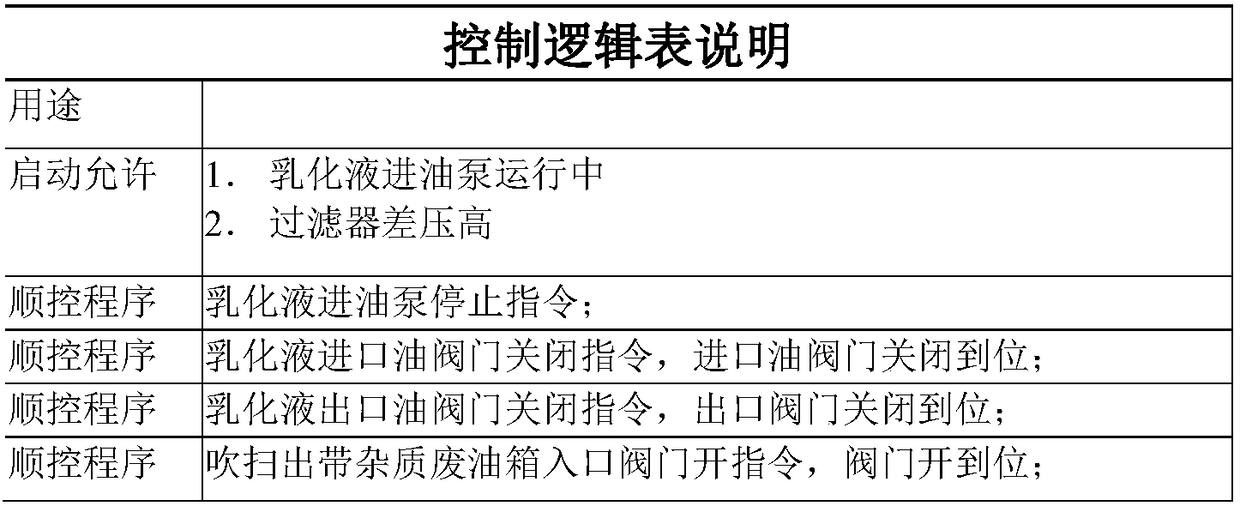

[0042] see Figure 1-2 shown,

[0043] The filtering and purging control equipment of the waste emulsion treatment system of the present invention is the same as the other patent application "Waste emulsion treatment system based on pulverized coal boiler in power plant" filed on the same day. The steam purges the filter, including the control box and the heat tracing system.

[0044] Including a control box 100 and a heat tracing system (not shown in the figure), the control box 100 is provided with an emulsion differential pressure detection branch that detects the input and output of the filter 1, and the two ends of the emulsion differential pressure detection branch are respectively Connect the two ends of the filter 1, that is, the oil inlet end and the oil outlet end of the emulsion through the filter 1. The detection branch is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com