Connector

A technology of connectors and contact parts, which is applied in the direction of connections, devices for preventing wrong connections, electrical components, etc. It can solve the problems of complex manufacturing process, easy deviation of protruding positions, and uniform contact pressure of difficult points, so as to prevent accidents The effect of maintaining stability in loosening and contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

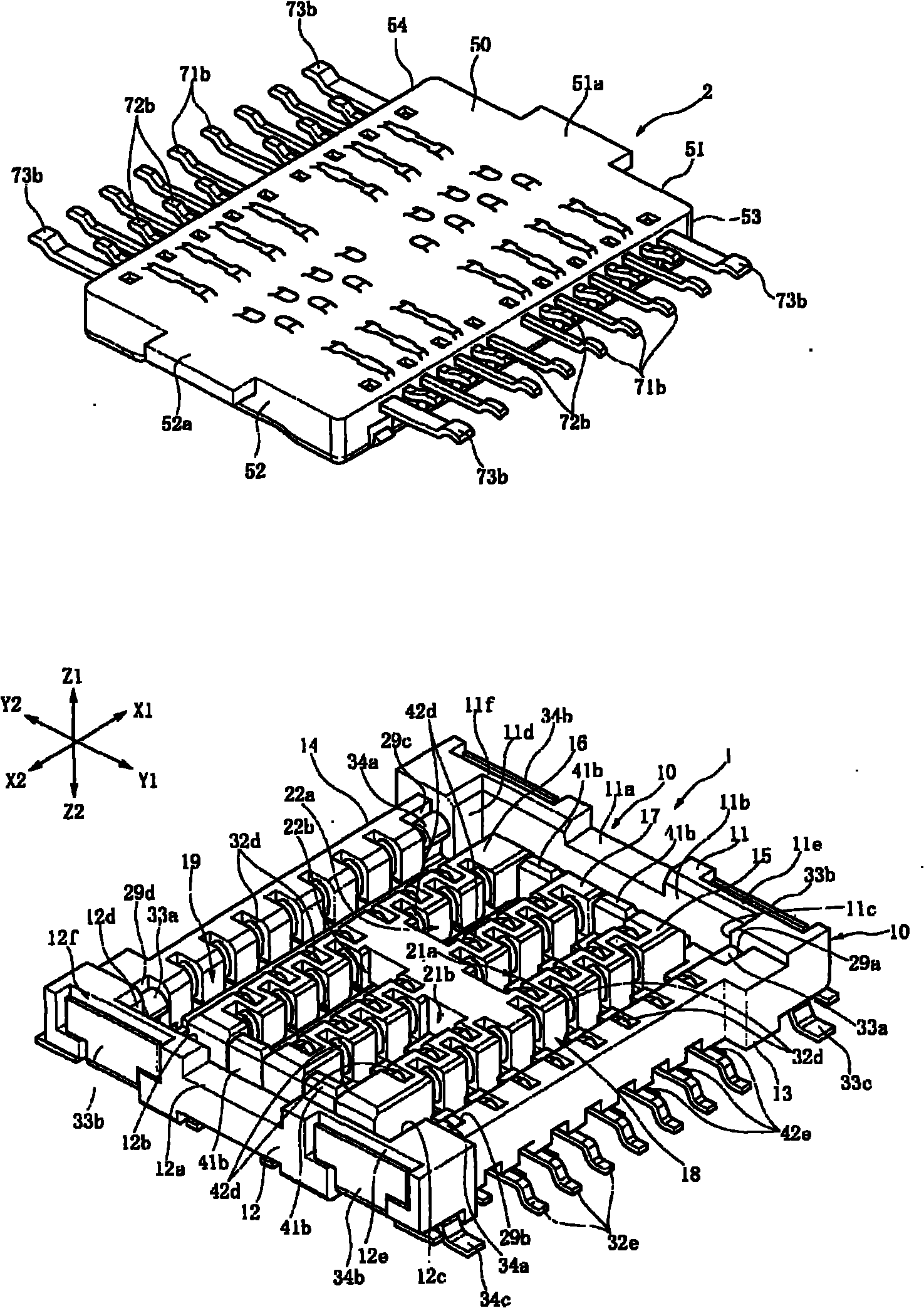

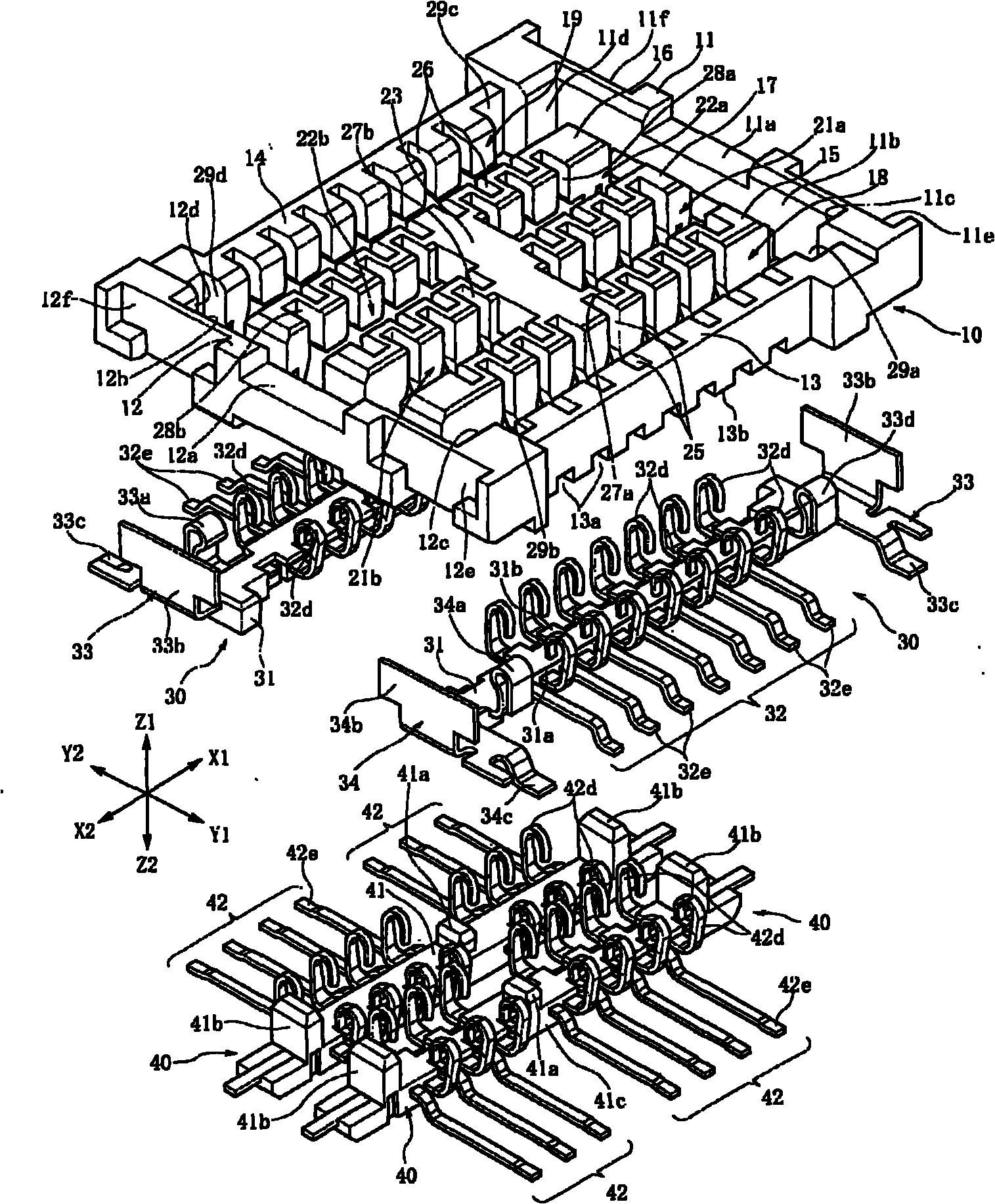

[0048] like figure 1 As shown, the connector has a connector 1 on the socket side and a connector 2 on the plug side. For example, the connector 1 on the socket side is mounted on the surface of the hard substrate, the connector 2 on the plug side is mounted on the flexible wiring board, and the connector 2 on the plug side is combined with the connector 1 on the socket side to form flexible wiring. The conduction part of the substrate and the conduction part of the hard substrate are independently conducted.

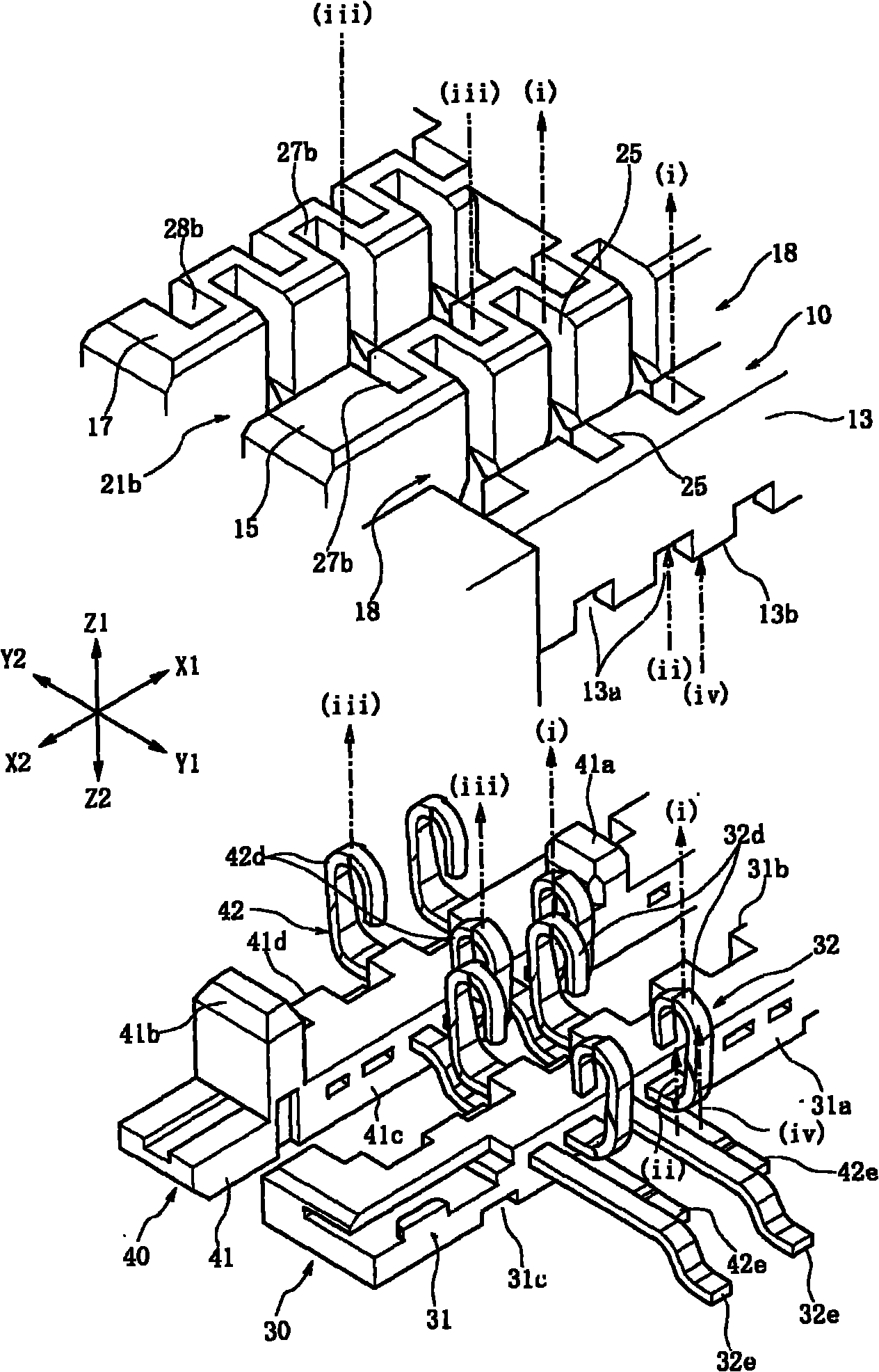

[0049] The connector 1 on the receptacle side has a receptacle main body 10 made of synthetic resin. The Z1 side (upper side) of the receptacle main body 10 is a connecting side to be coupled with the plug-side connector 2 , and the Z2 side (lower side) is a fixed side facing the board. In addition, the X1 side is the front, the X2 side is the rear, the Y1 side is the right side, and the Y2 side is the left side.

[0050] (Structure of the connector on the socket sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com