Multiphase flow measurement

A liquid flow, multiphase mixture technology, applied in the field of multiphase flow measurement, which can solve the problems of measuring hold-up and WLR, increasing cost, and being unusable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description only provides preferred exemplary embodiment(s), and is not intended to limit the protection scope, applicability, or structure of the present disclosure. On the contrary, the subsequent description of the preferred exemplary embodiment(s) will provide those skilled in the art with instructions for being able to implement the preferred exemplary embodiment. It should be understood that various changes can be made to the function and arrangement of the elements without departing from the spirit and protection scope of the appended claims.

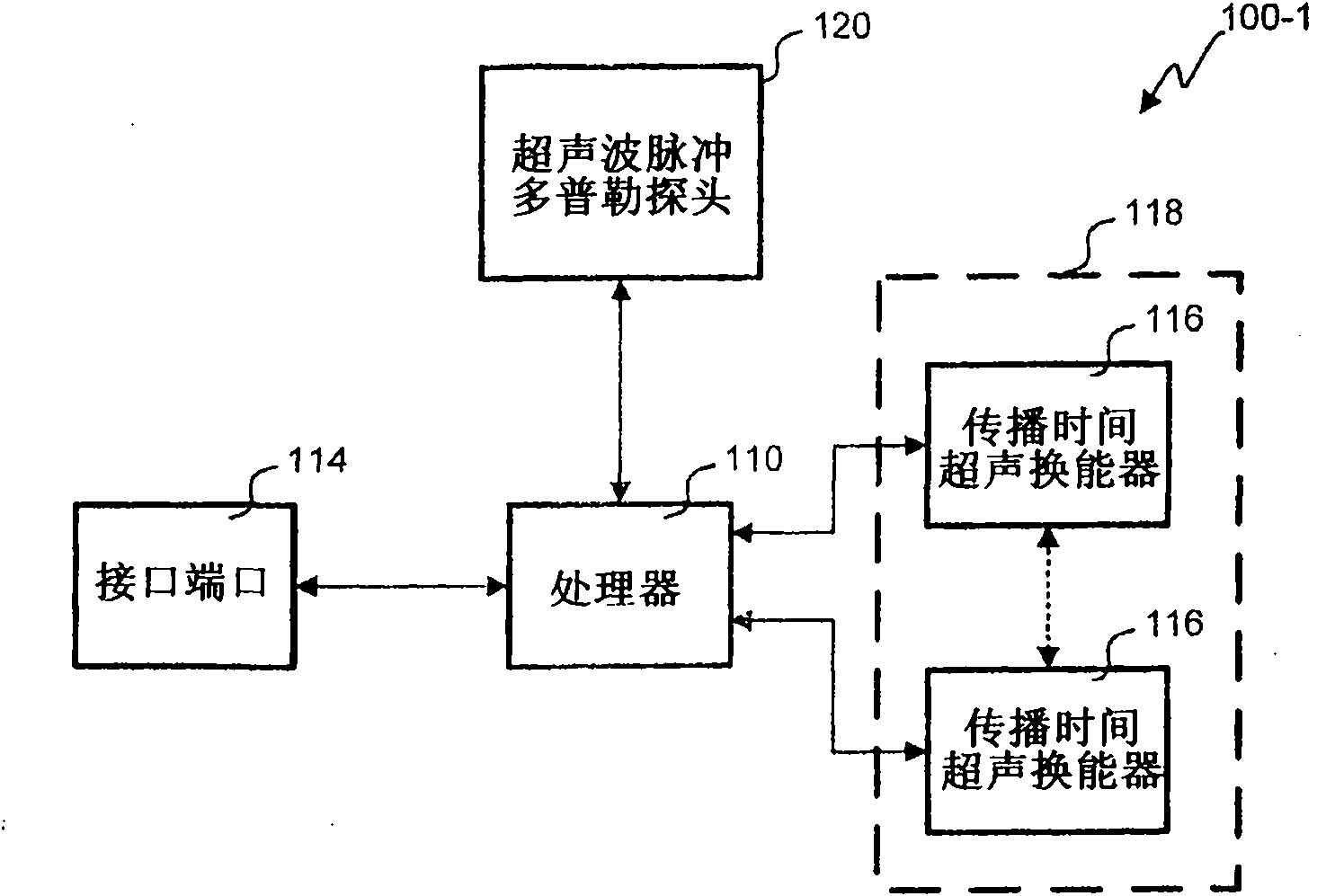

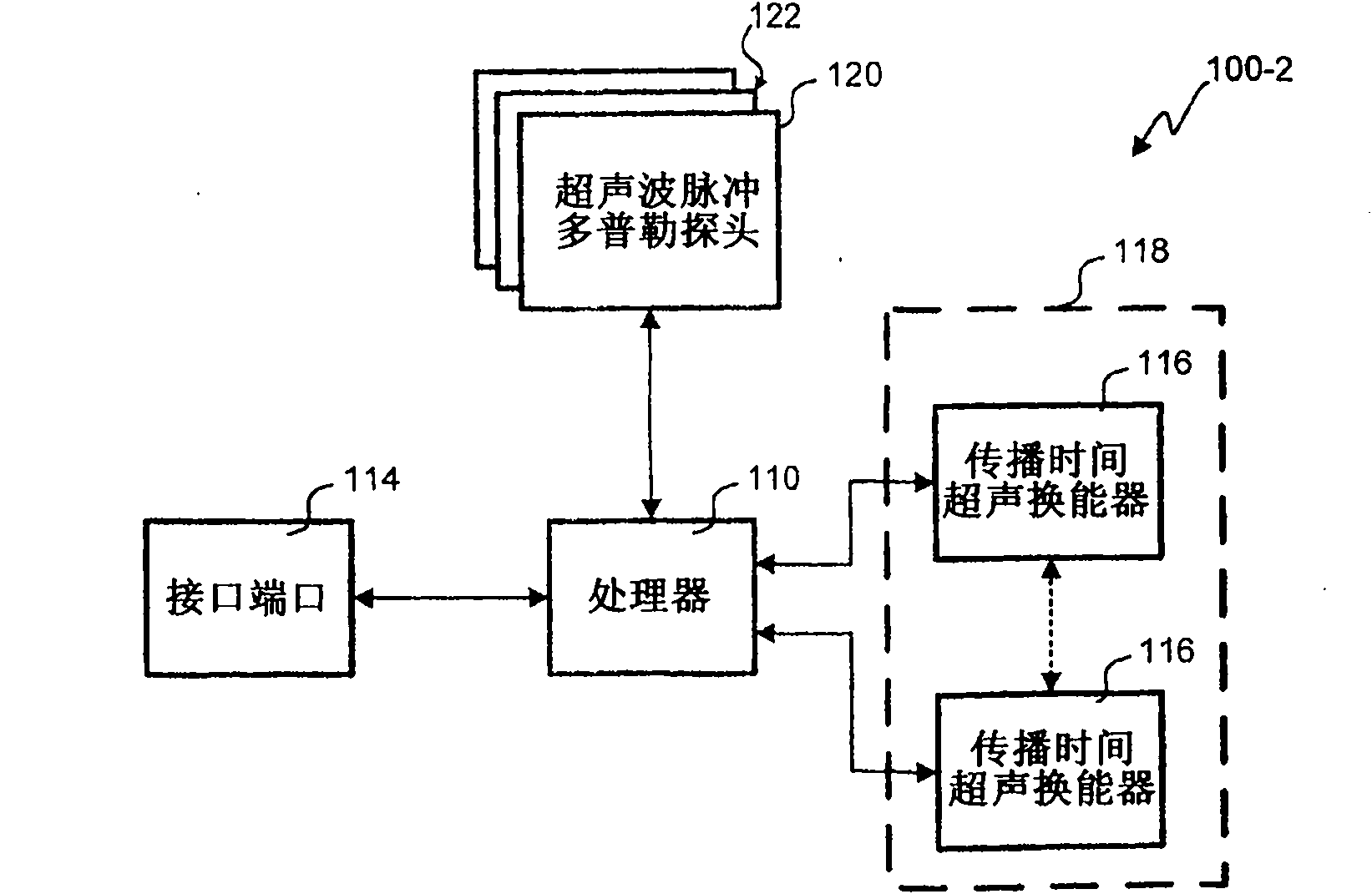

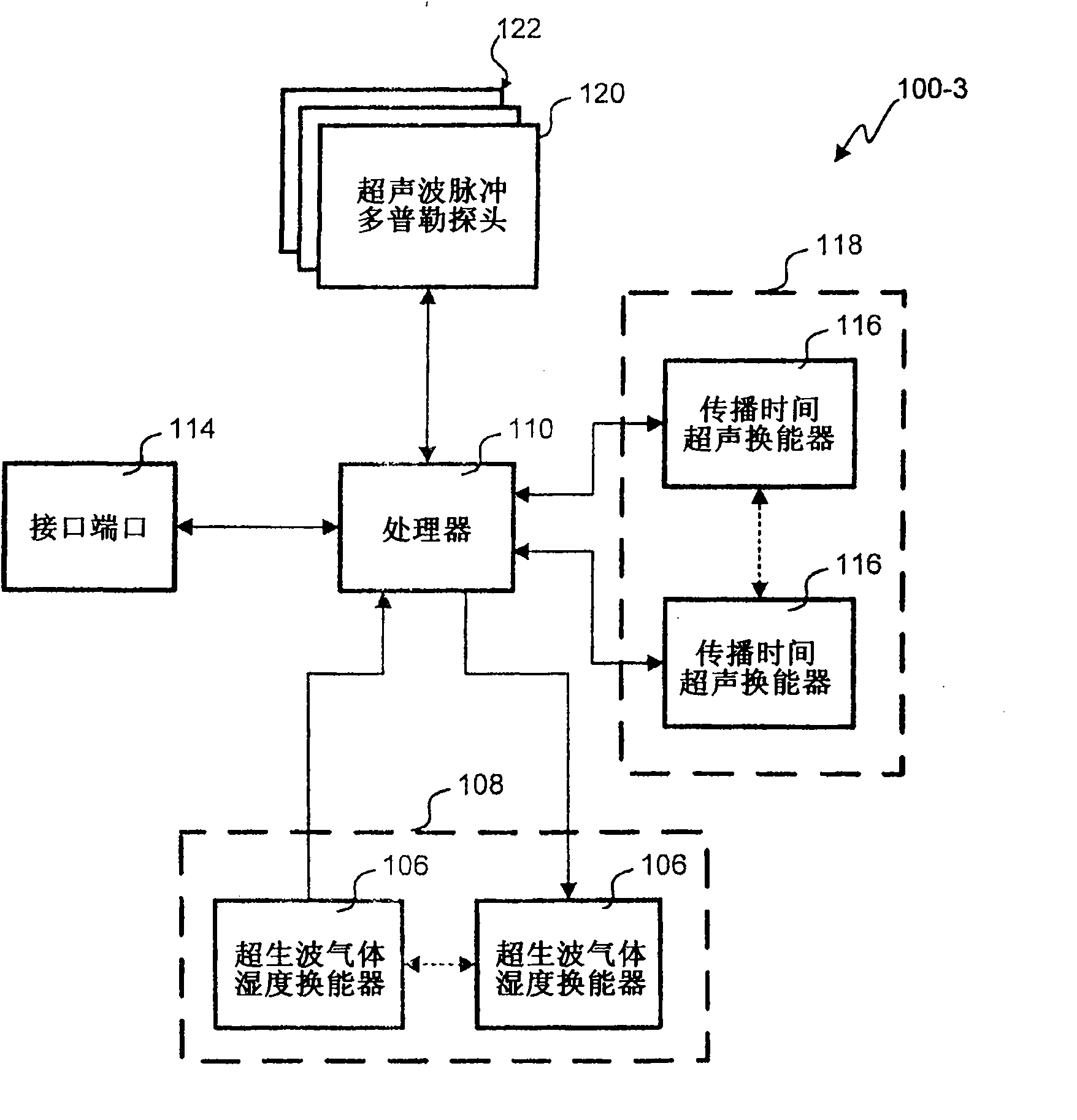

[0023] In some aspects, the time-of-flight ultrasonic transducer can be positioned close to or above the centerline of the pipe or on the pipe where the gas phase can flow in the pipe to measure the gas phase in the pipe . Ultrasonic pulse Doppler probe(s) and / or electromagnetic (EM) transmitters and receivers can be arranged around the bottom part of the pipe or at a location where laminar flow can allow the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com