Hydraulic split block structure positioning clamp of free curve surface work pieces

A surface workpiece and structure positioning technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as increasing the cost of free-form surface workpieces, increasing the cycle of processing or measurement, and affecting work efficiency, achieving a high degree of automation and versatility. Good, improve the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

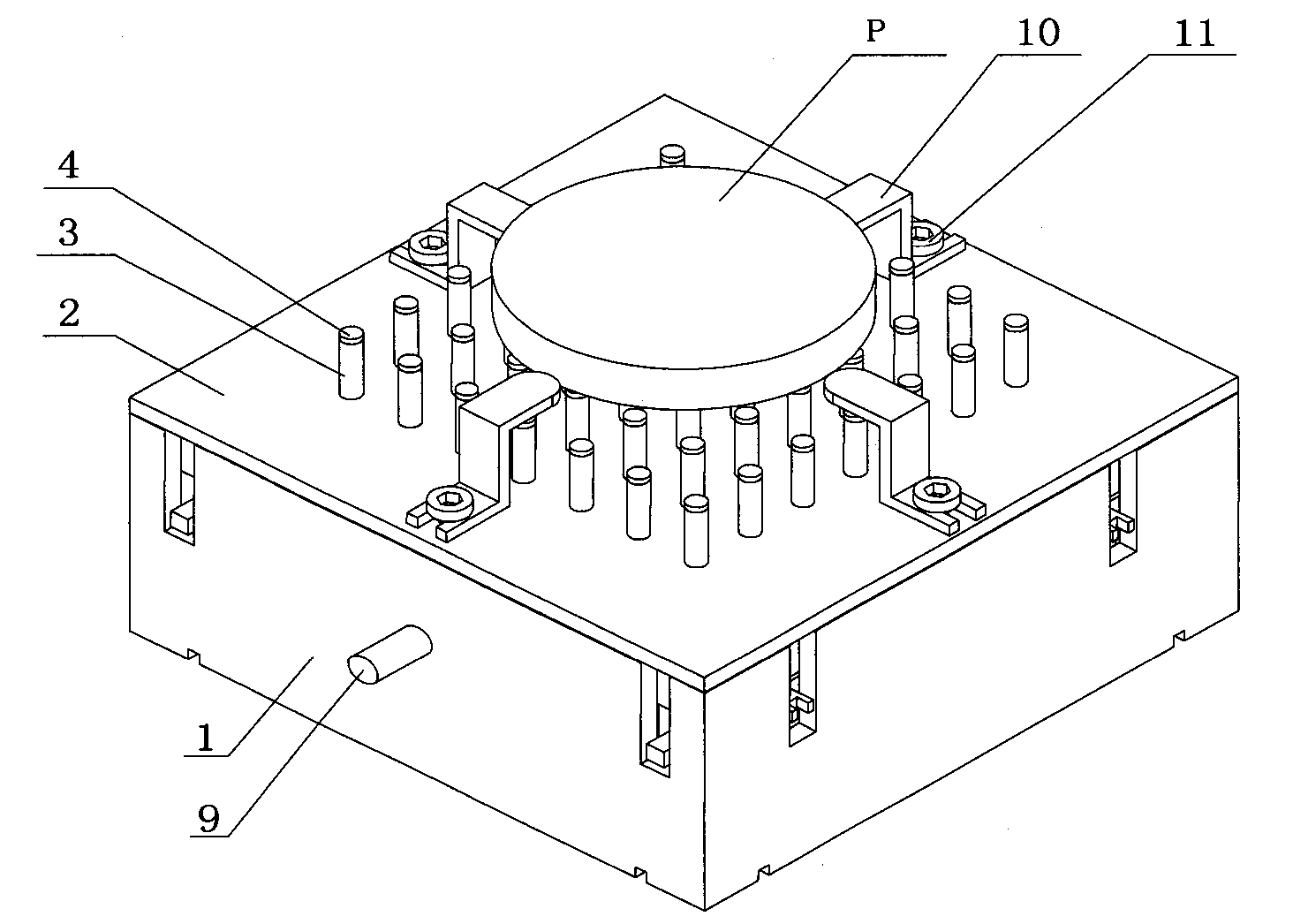

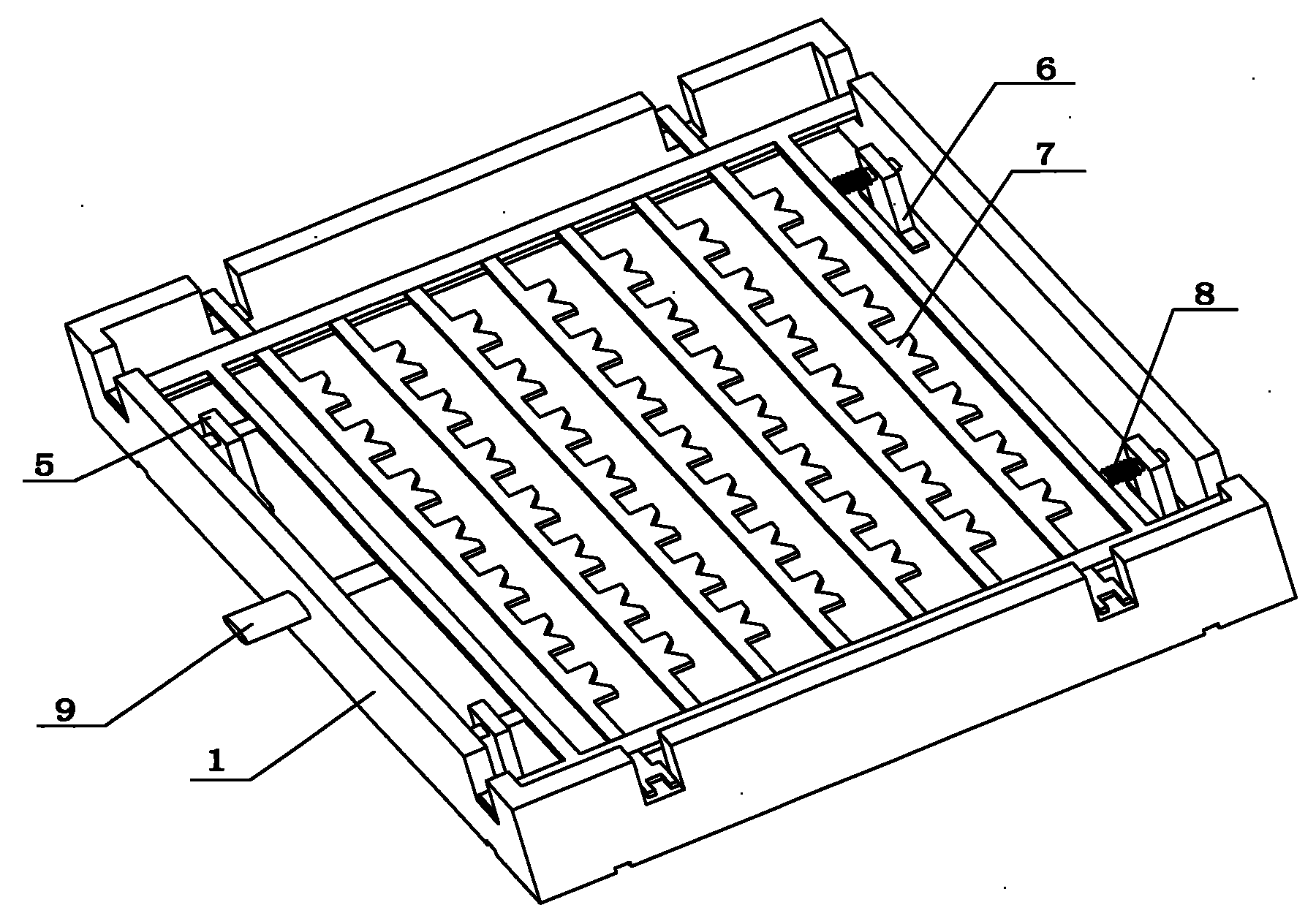

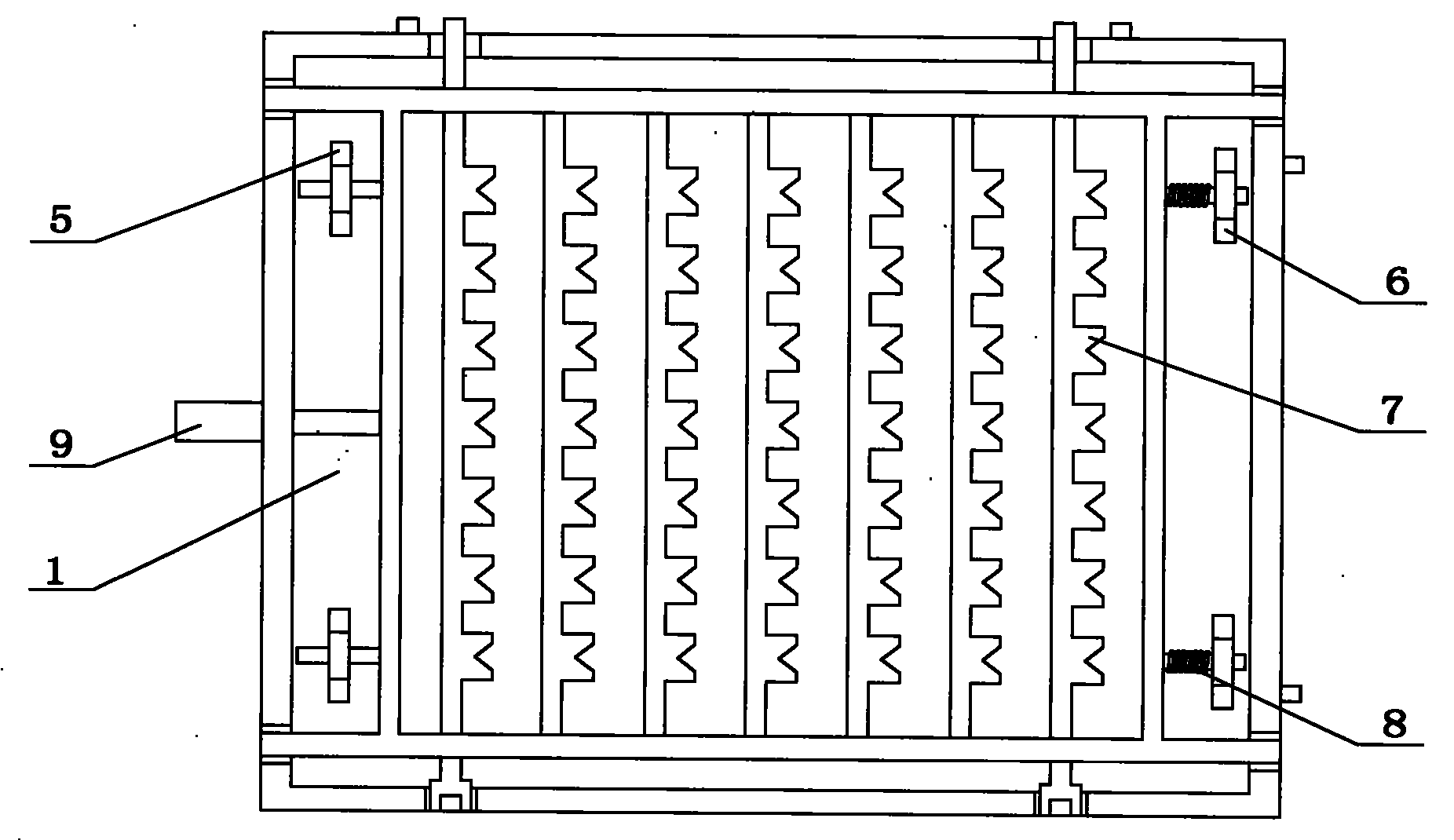

[0025] see Figure 1~3 , 10 and 11, the embodiment of the present invention is provided with base 1, upper cover plate 2, one-way hydraulic cylinder 3, piezoelectric ceramics 4, left bracket 5, right bracket 6, hydraulic cylinder clamping frame 7, return spring 8, lock Tight hydraulic cylinder 9, fixed top block 10, screw 11, oil cylinder 12, filter 13, oil pump 14, throttle valve 15, relief valve 16 and reversing valve 17. Among them, the upper cover plate 2 is covered on the base 1, one end of the one-way hydraulic cylinder 3 is installed on the base 1, and one end passes through the upper cover plate 2 to expose outside and paste piezoelectric ceramics 4; oil cylinder 12, filter 13, oil pump 14 , throttle valve 15, overflow valve 16 and one-way hydraulic cylinder 3 form a hydraulic circuit for controlling the movement of one-way hydraulic cylinder 3; left bracket 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com