Walking-beam conveyor

A technology of lifting beams and conveyors, applied in the directions of conveyors, transportation and packaging, can solve problems such as overloading of lifting beams, and achieve the effect of low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

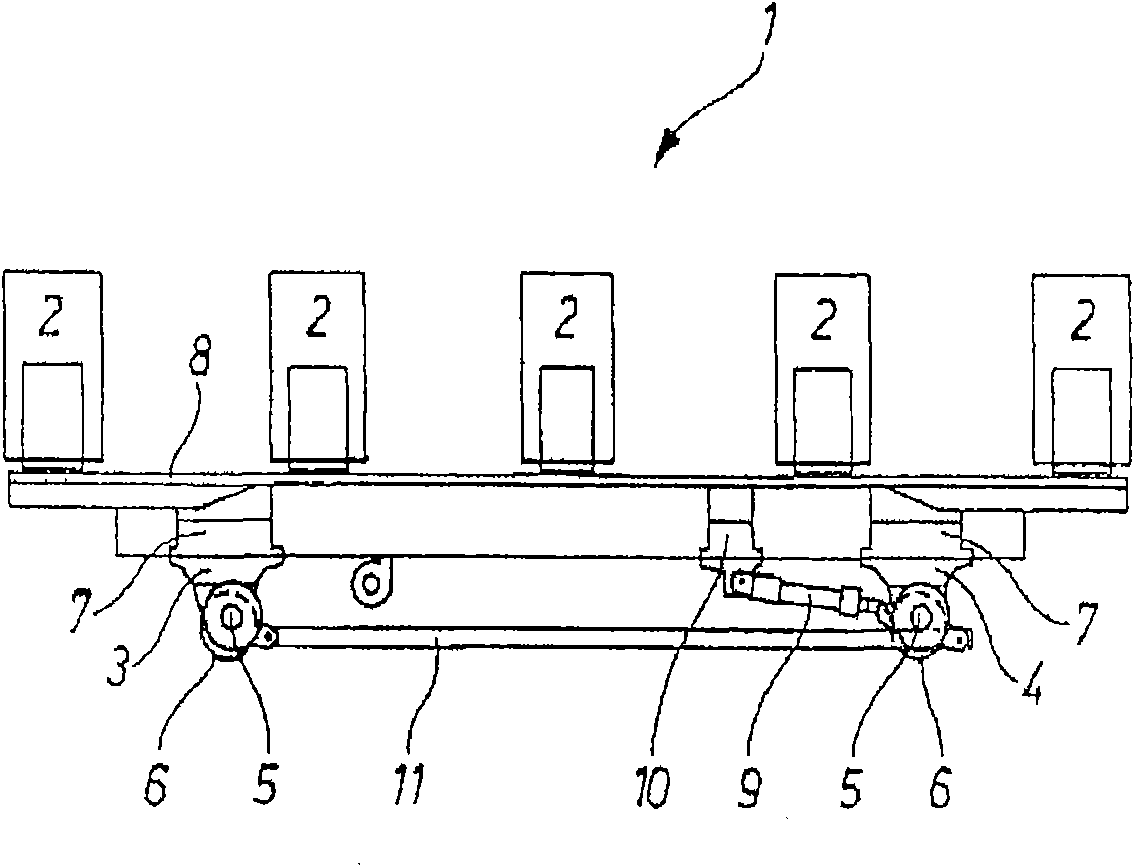

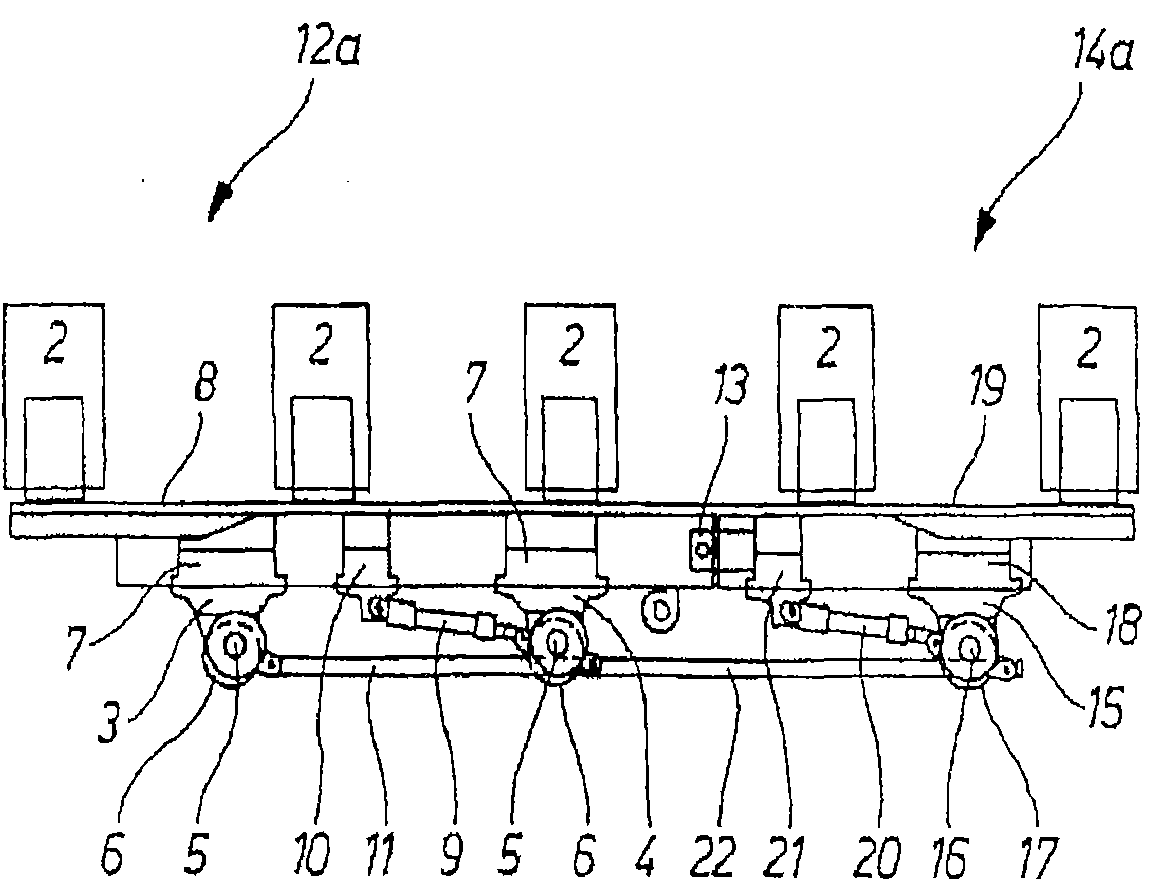

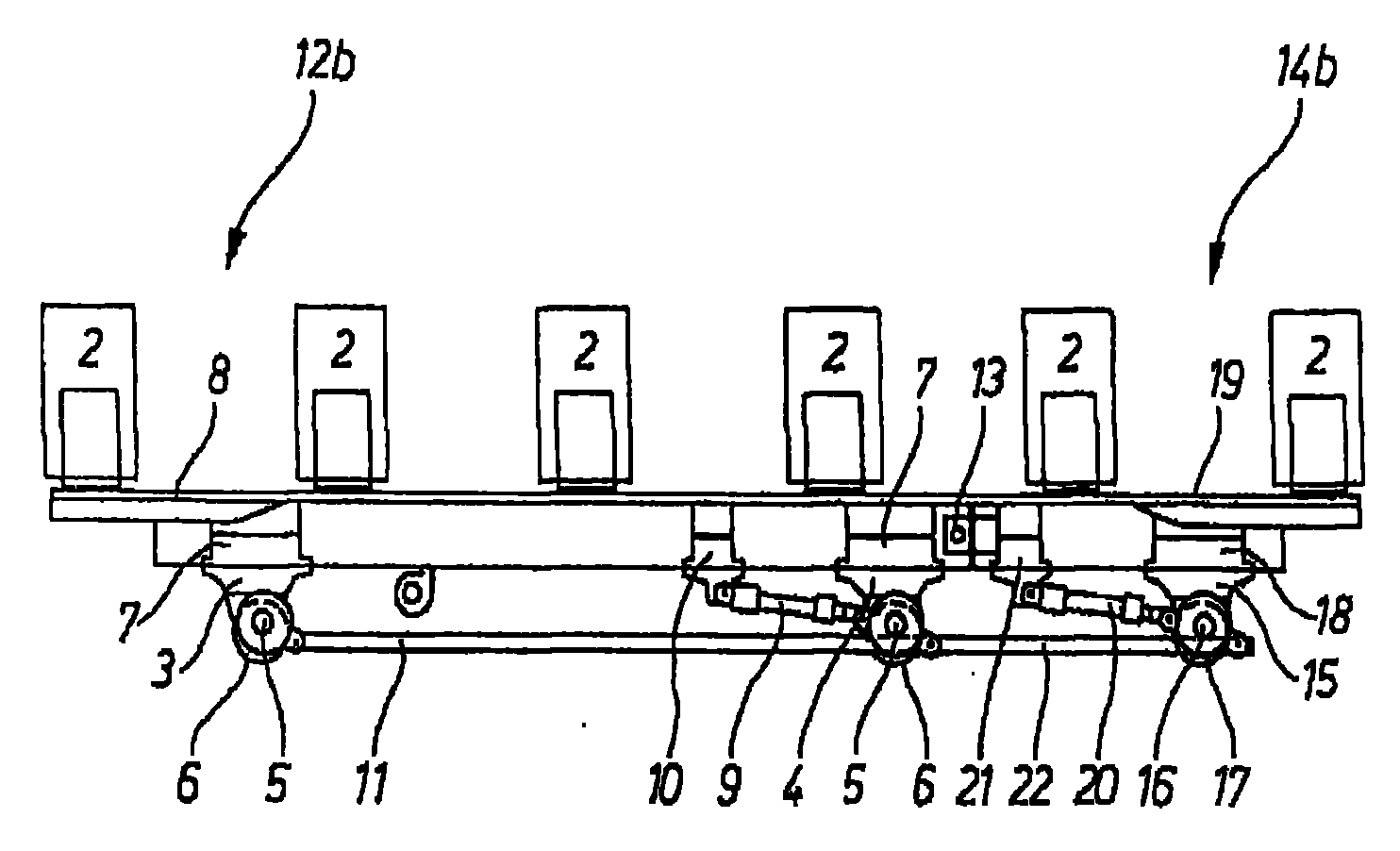

[0043] figure 1 Shown is a conventional lifting beam 1 on a conveyor line for periodically conveying (shown here) five coils or coils 2 .

[0044] The lifting beam 1 is a continuous conveyor that conveys the coils 2 placed at fixed intervals through the superposition of vertical movement and horizontal movement.

[0045] The traveling mechanism of lifting beam 1 is made of two sub-frames 3, 4, and these two sub-frames are respectively equipped with a shaft 5 and a plurality of rollers 6 connected on the shaft. When the lifting beam 1 moves horizontally or conveys, the rollers 6 move on the guide rails of the rail system inside the conveying equipment.

[0046] Each of the two sub-frames 3,4 is arranged with a lifting device 7 for lifting the crossbeam 8 carrying the coiled material 2. As an alternative and optional solution, it is also possible to pass the eccentric structure built in the sub-frames 3,4. Lifting mechanism is used to facilitate this vertical movement, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com