Grease producing method and grease leacher

A technology for leaching and oil extraction, applied in the field of oil extraction, can solve the problems of dilute mixed oil concentration, unfavorable industrial production, and difficulty in increasing filtration, and achieves the effects of low equipment cost and operating cost, convenient operation and management, and reduced power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

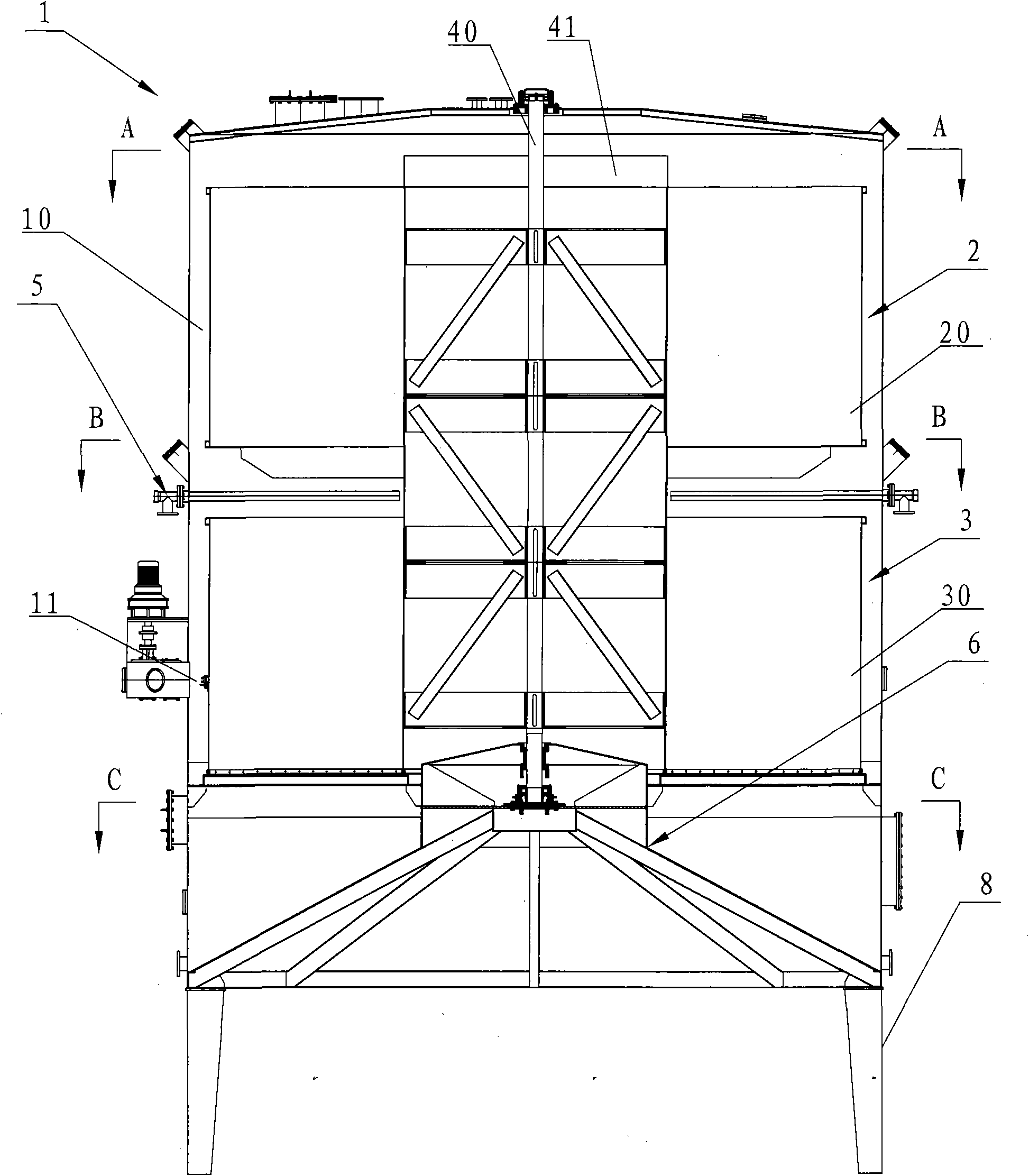

[0041] This embodiment provides a hybrid grease extractor. Such as Figures 1 to 6As shown, the grease extractor includes a support 8, a circular cylinder 1 supported by the support 8, a first leaching unit 2 and a second leaching unit 3 respectively arranged on the upper layer 10 and the lower layer 11 of the cylinder 1, driving the first leaching The driving mechanism for the rotation of the unit 2 and the second leaching unit 3, the spray device 5, the mixing oil bucket 6 arranged under the second leaching unit 3, and the slag unloading mechanism.

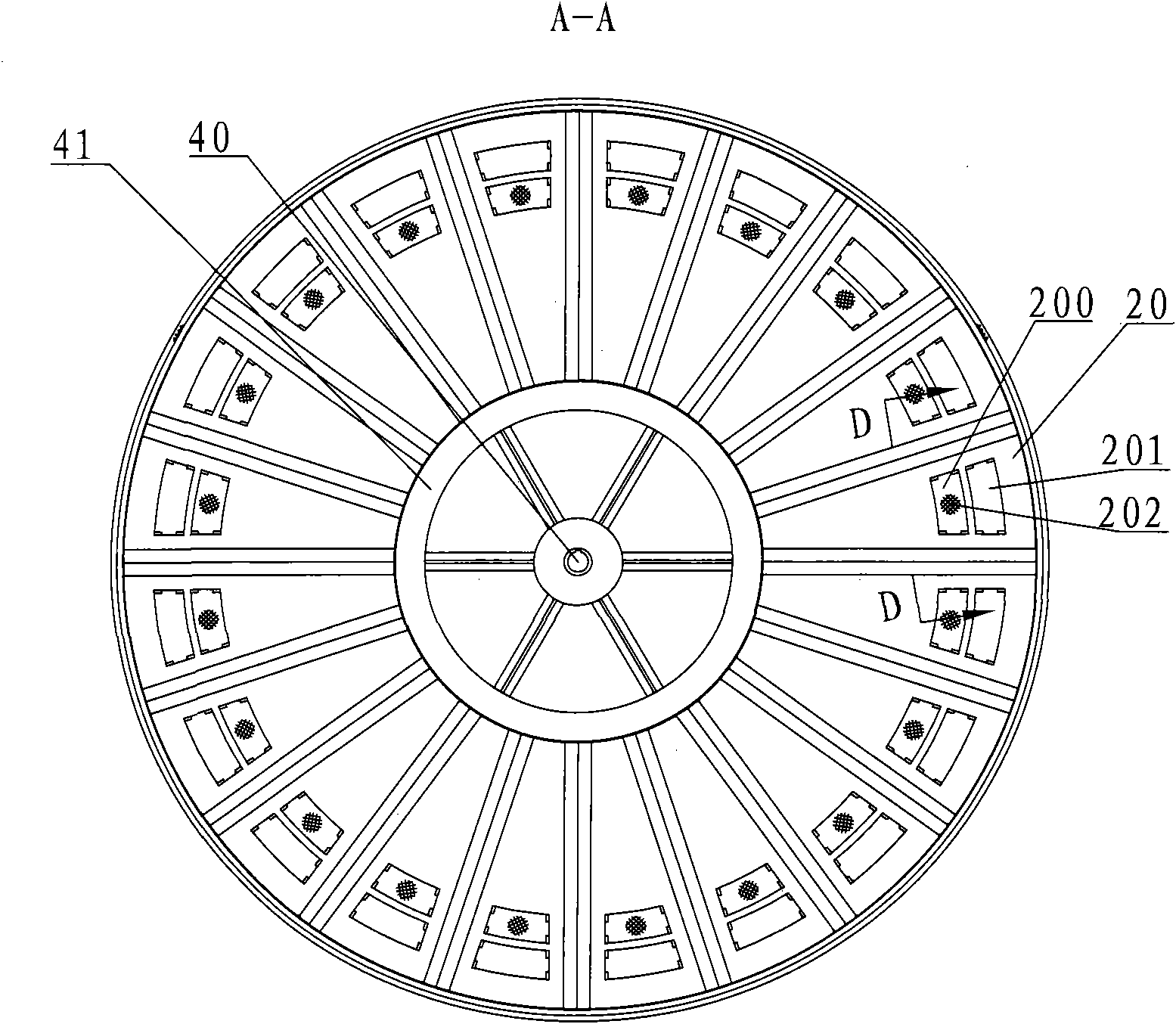

[0042] The driving mechanism includes a main shaft 40 driven by a motor, and a rotor 41 whose center is fixedly connected with the main shaft 40 . The first leaching unit 2 includes 20 first grids 20 uniformly distributed along the circumferential direction of the rotor 41 . The second leaching unit 3 includes 20 second grids 30 corresponding to the 20 first grids 20 . A first opening and a second opening are provided on the ...

Embodiment 2

[0046] This embodiment provides a method for oil extraction using the oil extractor of Example 1, the process is the same as above, and the process conditions are as follows:

[0047] 1. The water content of the incoming oil is 5% to 6%, the thickness is ≤13mm, the powder degree is ≤15% (30 mesh), the solvent is the national standard No. 6 solvent oil, and the concentration of the oil in the mixed oil depends on the content of the oil in the oil It is determined that the oil content of the oil is lower than that of the oil, and the oil content in the mixed oil that is finally discharged from the extractor is controlled to be the oil content of the raw material α+5%.

[0048] 2. When the extractor is working, the vacuum degree is 2KPa, the temperature is 50°C, and the time for one revolution is 40-45 minutes, that is, the extraction time is 80-90 minutes.

[0049] 3. In the first compartment, the volume of the soaking agent (that is, the mixed oil with a suitable concentration)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com