Feeding and discharging plunger pump

A plunger pump, feeding and discharging technology, which is applied in the field of feeding and discharging plunger pumps, can solve the problems of short service life, extremely poor fluidity, and high temperature of the pump body, so as to increase the service life, reduce maintenance time, and reduce operation The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

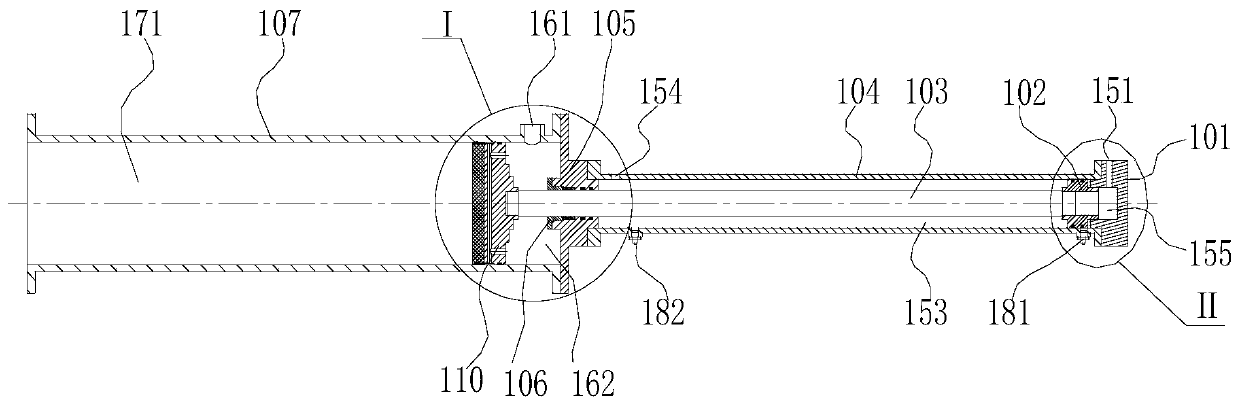

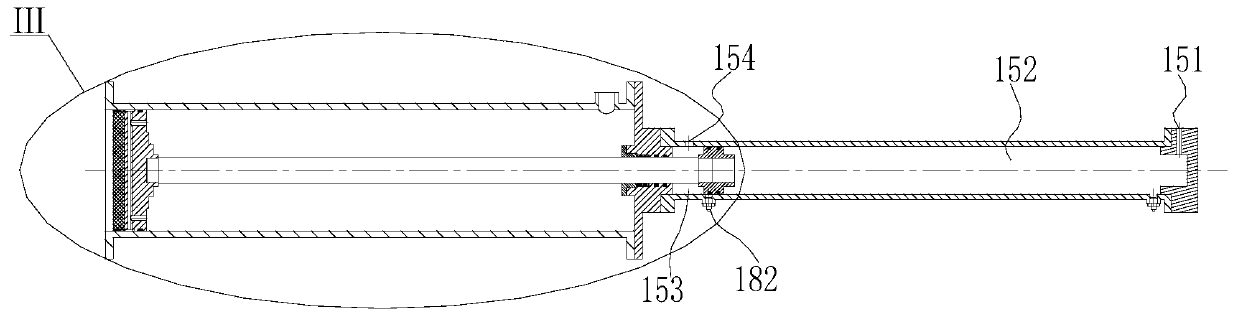

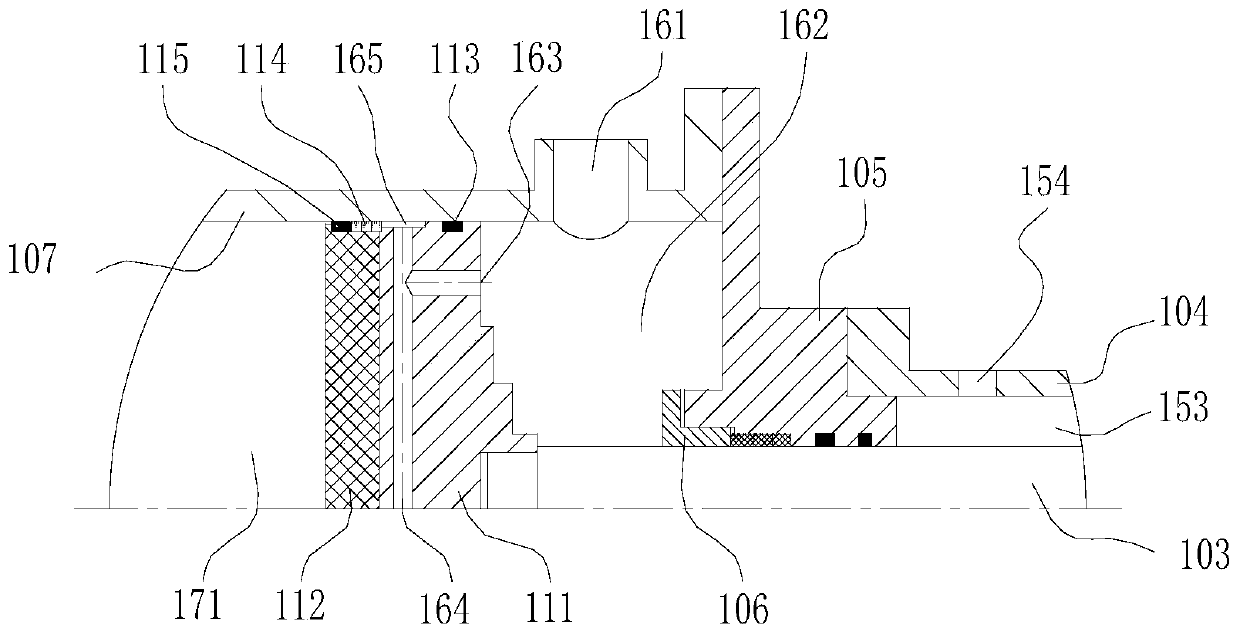

[0041] Such as Figure 1-5 As shown, the plunger pump device for feeding and discharging materials described in the present invention includes a hydraulic drive assembly and a material conveying assembly;

[0042]The hydraulic drive assembly includes a hydraulic cylinder block 104, a rear end cover 101, a hydraulic piston 102, and a piston rod 103. The inner cavity of the hydraulic cylinder block is installed in cooperation, and the front end of the side wall of the hydraulic cylinder block is provided with a front hydraulic oil filling port 154, and a groove 155 is provided on the end surface connecting the rear end cover with the internal cavity of the hydraulic cylinder block, and the groove passes through the rear hydraulic oil filling port 151 communicates with the outside.

[0043] The material conveying assembly includes a material cylinder 107 and a material piston 110, the material piston is installed at the front end of the piston rod, the material piston is located...

Embodiment 2

[0071] Such as Figure 6-8 As shown, the difference between this embodiment and embodiment 1 is:

[0072] The piston rod has a piston rod inner chamber 205, a water pipe 201 is installed in the piston rod inner chamber, a lock nut 203 and a guide sleeve 202 are installed at the front end of the water pipe, the outer wall of the guide sleeve has a seal, the end of the water pipe passes through the rear end cover, and is connected with the rear end cover. The end cover is fixedly connected, the water inlet hole is located at the center of the base, and the front end of the piston rod is connected to the water inlet hole; there is an annular groove 206 on the contact surface between the pressure bearing plate and the material cylinder, and the cut surface of the annular groove has a slope, close to the base The depth of the annular groove on one side is relatively deep, and the annular groove communicates with the annular water tank.

[0073] The outside of the water injection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com