Bearing and sliding device for stretching and positioning in formwork engineering

A formwork engineering and sliding device technology, which is applied in the treatment of formwork, the preparation of building components on site, and construction, etc., can solve the problems of operation efficiency limitation, difficulty in disassembly and assembly of large formwork, etc., and achieve the effect of improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

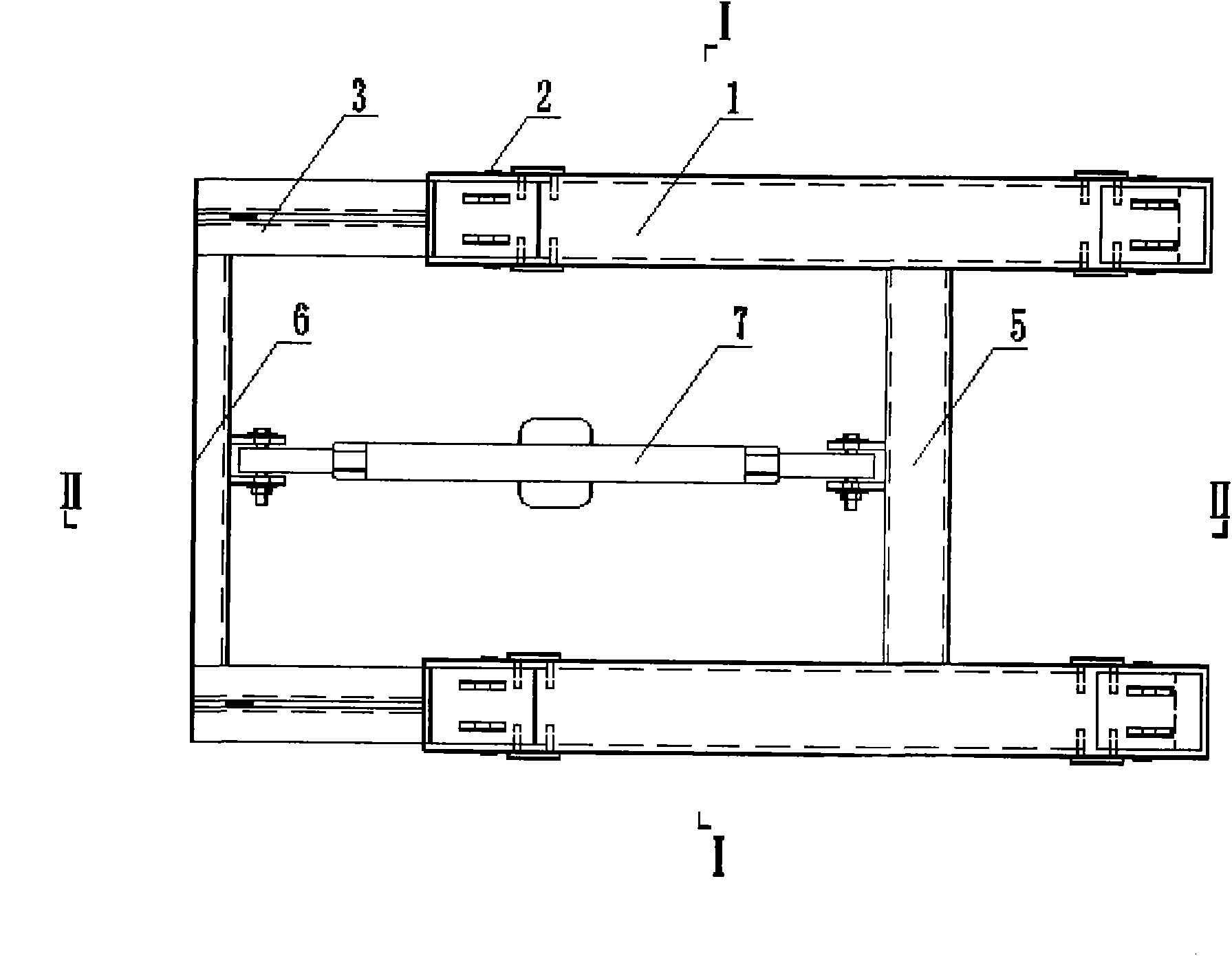

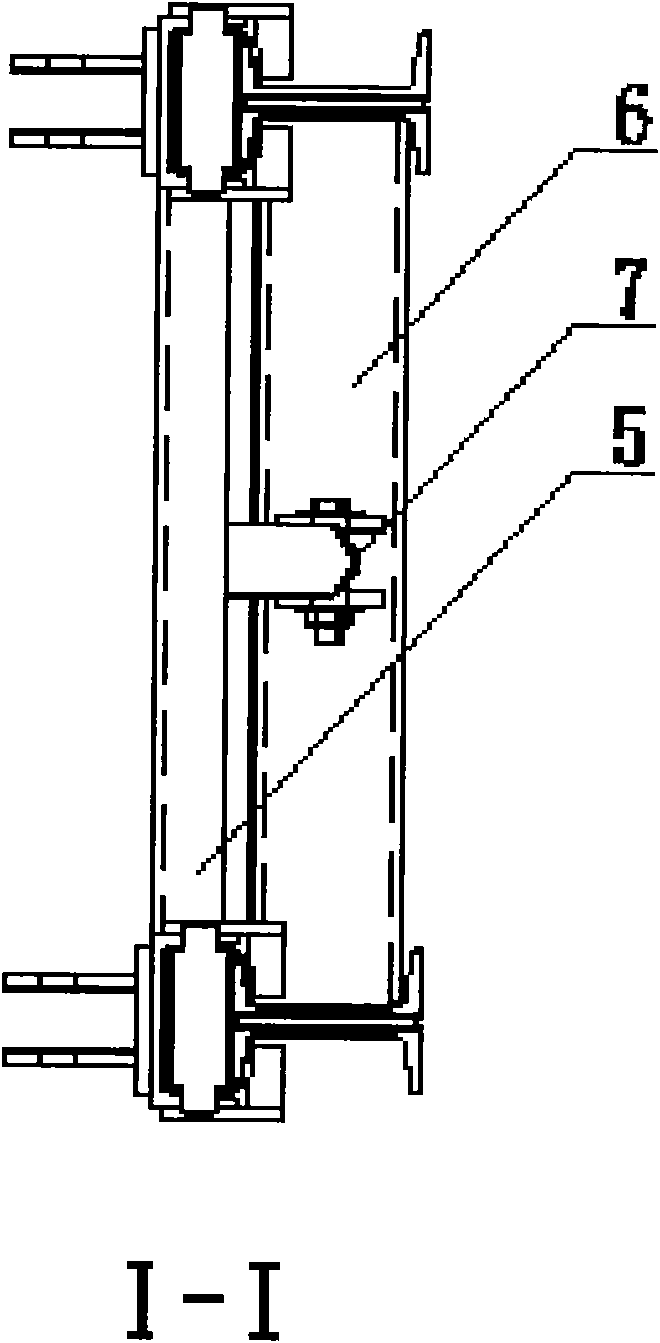

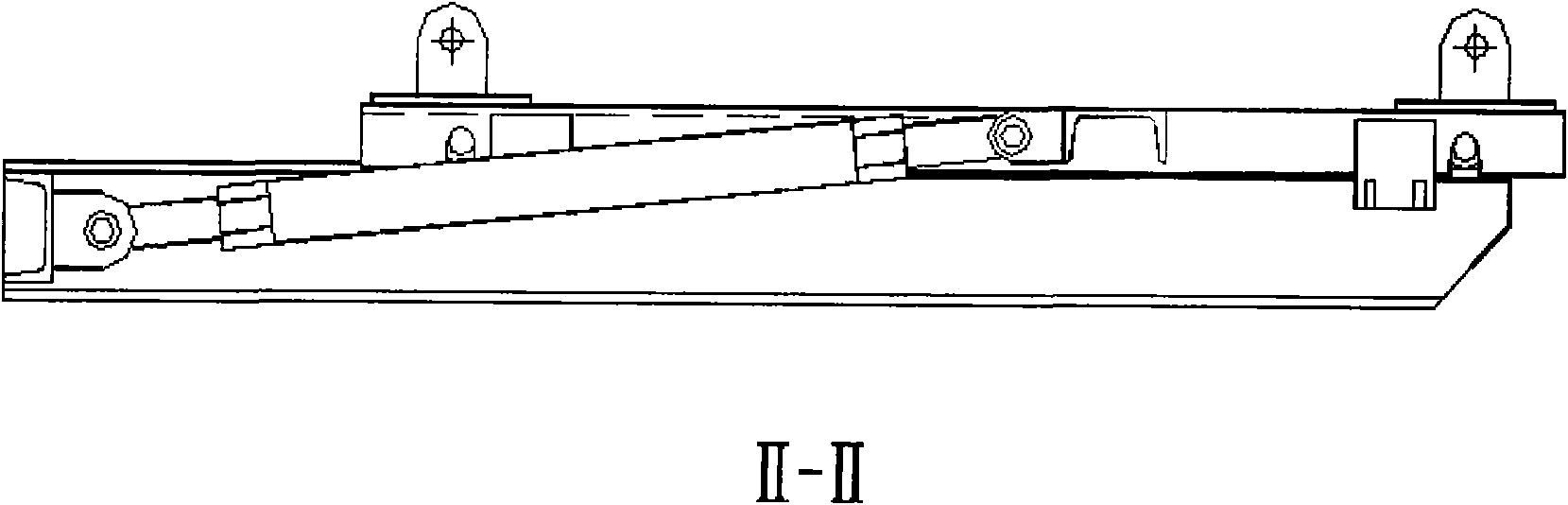

[0013] Refer to attached figure 1 and 2 , the present invention is by reverse " U " shape groove load-bearing beam (1), roller shaft (2), " I " font track beam (3), double " L " type groove plate (4), connecting horizontal bar ( 5), connecting channel steel (6) and adjusting bar (7) form. Through the steel sliding roller shaft (2), the upper inverted "U"-shaped groove load-bearing beam (1) and the lower "I"-shaped track beam (3) produce two-way sliding. The two ends of the load-bearing beam (1) are provided with double "L"-shaped grooved plates (4), which extend into the lower part of the upper flange of the "I"-shaped track beam (3) to limit the displacement in the vertical direction. Two load-bearing beams (1) that are parallel to each other and whose cross-sections are reversed "U" grooves are connected by a connecting horizontal bar (5) with double connecting ear plates in the middle; two parallel "I" shaped track beams (3 ) is connected at one end by a connecting chann...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap