Inner and outer barrel type free-standing steel chimney

A self-supporting, inner and outer cylinder technology, applied in the field of steel structure chimneys, can solve the problems of difficult manufacturing and installation process, and achieve the effect of convenient and labor-saving installation process and reliable installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

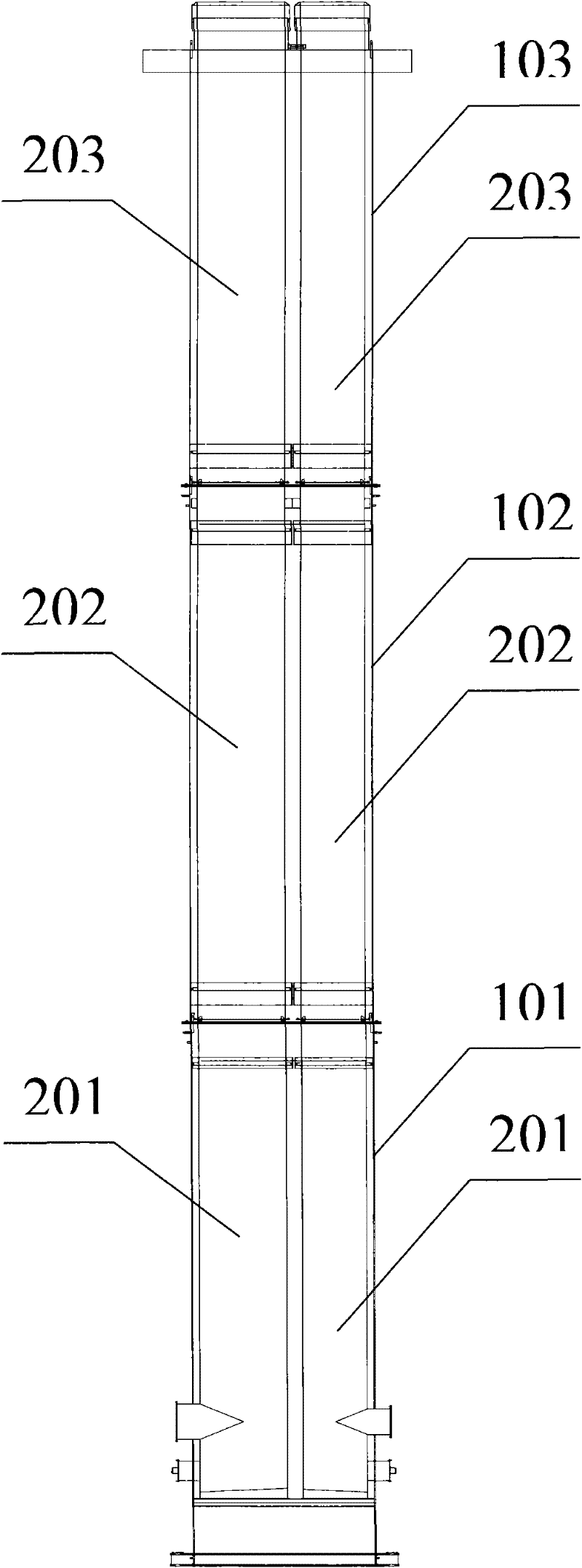

[0026] Embodiment: a kind of inner and outer cylinder type self-supporting steel chimney, as figure 1 As shown, it is composed of a carbon steel outer cylinder 1 and two stainless steel inner cylinders 2. The carbon steel outer cylinder 1 has a diameter of 2300mm and a height of 48500mm, and the stainless steel inner cylinder 2 has diameters of Φ800mm and 1100mm respectively. The height is 50000mm, that is, the top of the stainless steel inner cylinder 2 is 1500mm higher than the top of the carbon steel outer cylinder 1. Both the carbon steel outer cylinder 1 and the stainless steel inner cylinder 2 are composed of three sections.

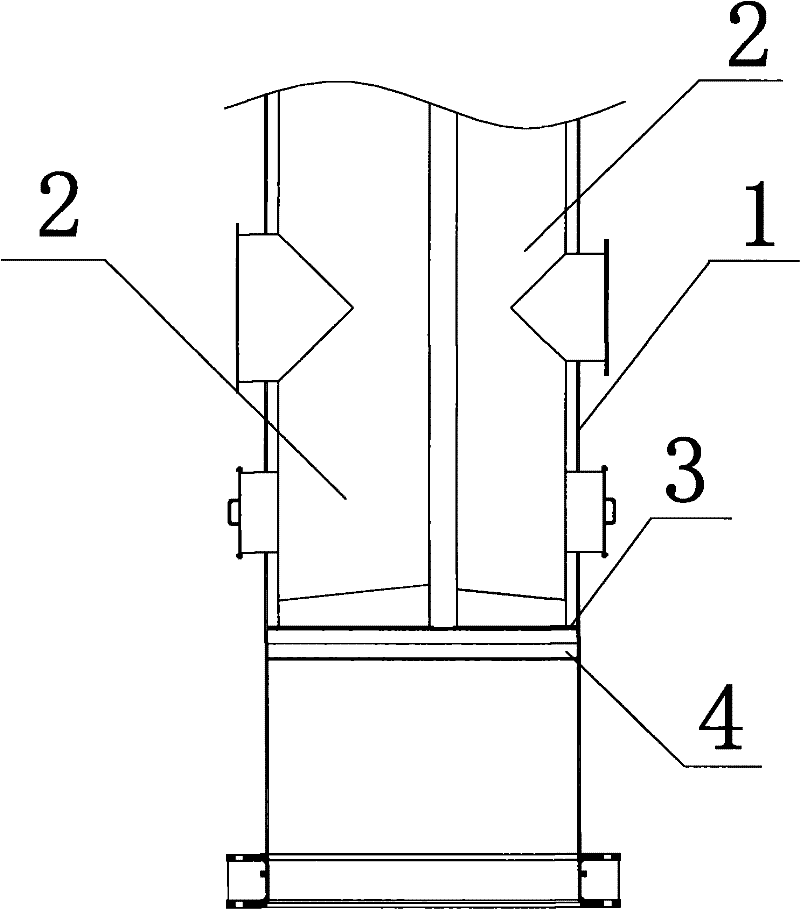

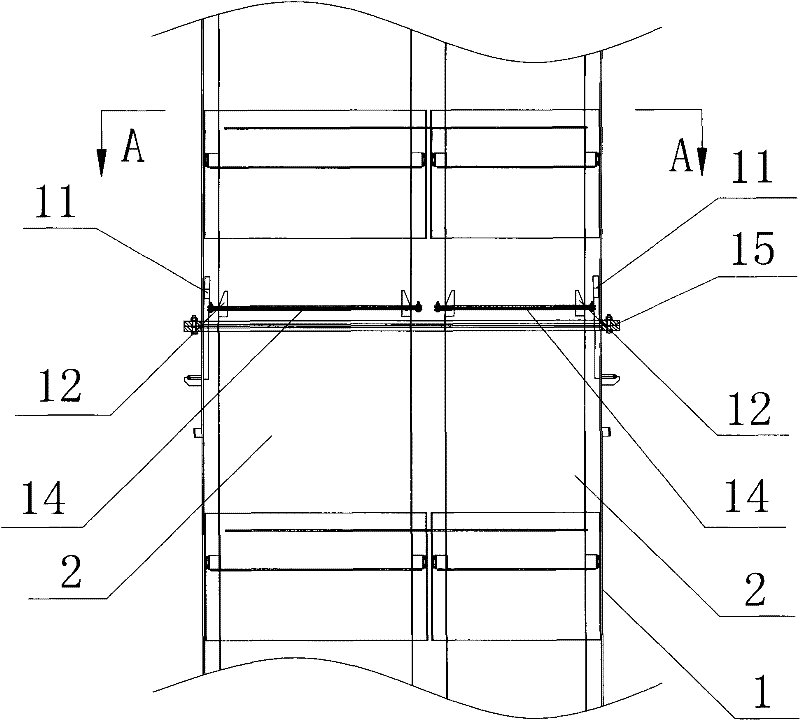

[0027] Such as figure 2 As shown, at a height of 3000 mm from the bottom of the base flange of the lower carbon steel outer cylinder 101, reinforcements such as steel support bottom plate 3 and support channel steel 4 are used to weld and fix the lower carbon steel outer cylinder 101, and the bottom of the lower stainless steel inner cylinder 201...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com