Fixing method for electric cabinet of coal mining machine and fixing structure for electric cabinet of coal mining machine

A fixed method and fixed structure technology, applied in the direction of support structure installation, printed circuit board socket, etc., can solve the problems of screw group installation difficulty, inconvenient maintenance and electrical components damage, etc., to achieve stable and reliable box installation position, easy maintenance Convenient and fast, the effect of reducing adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

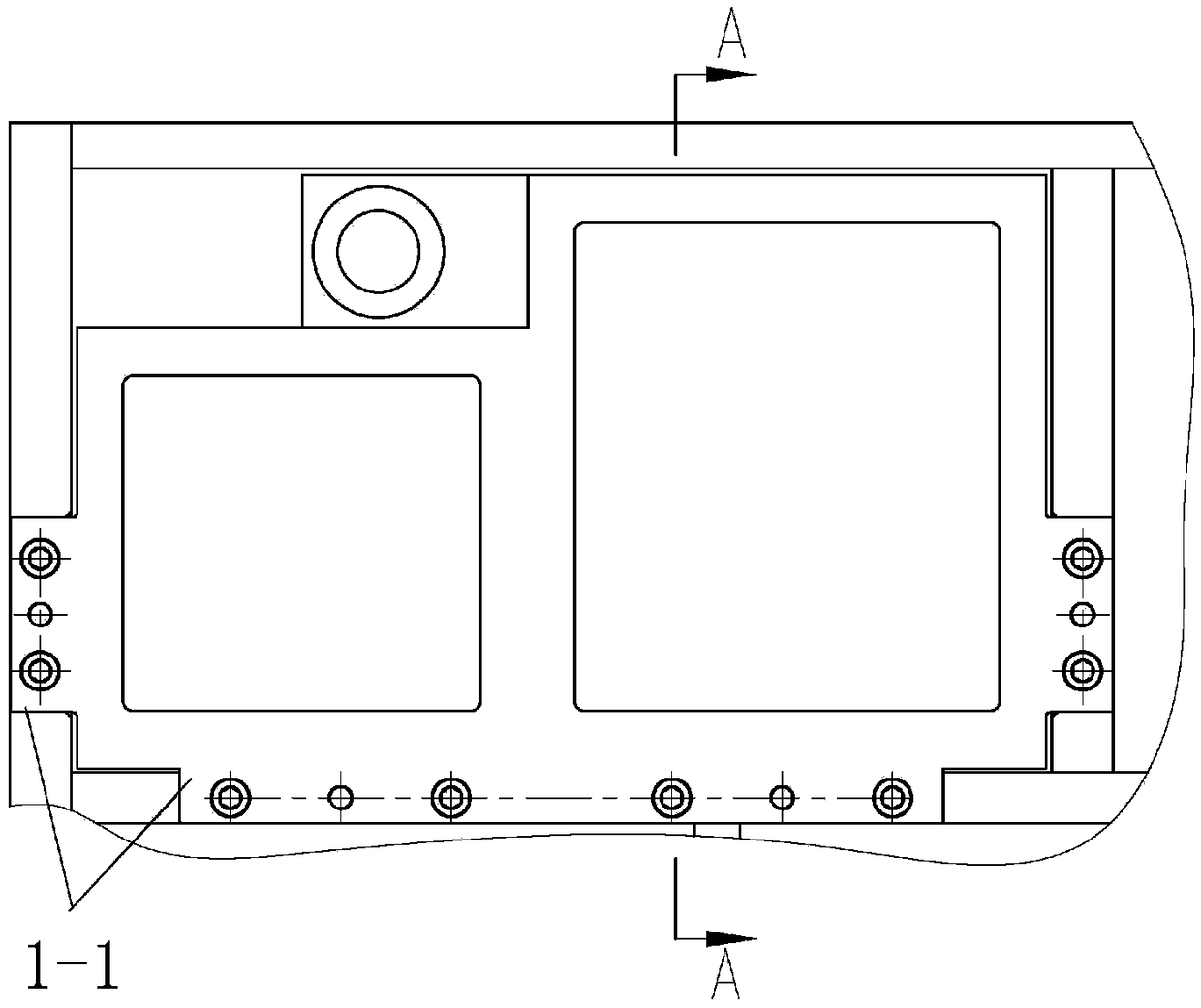

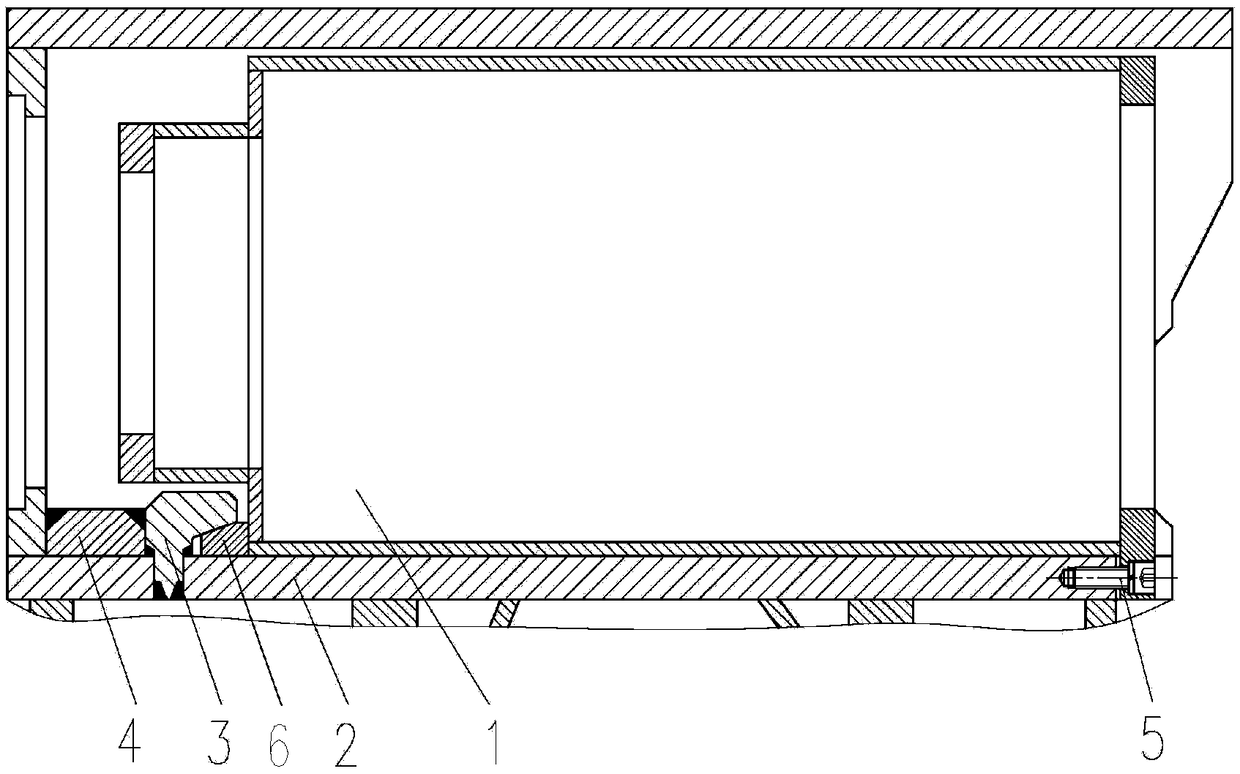

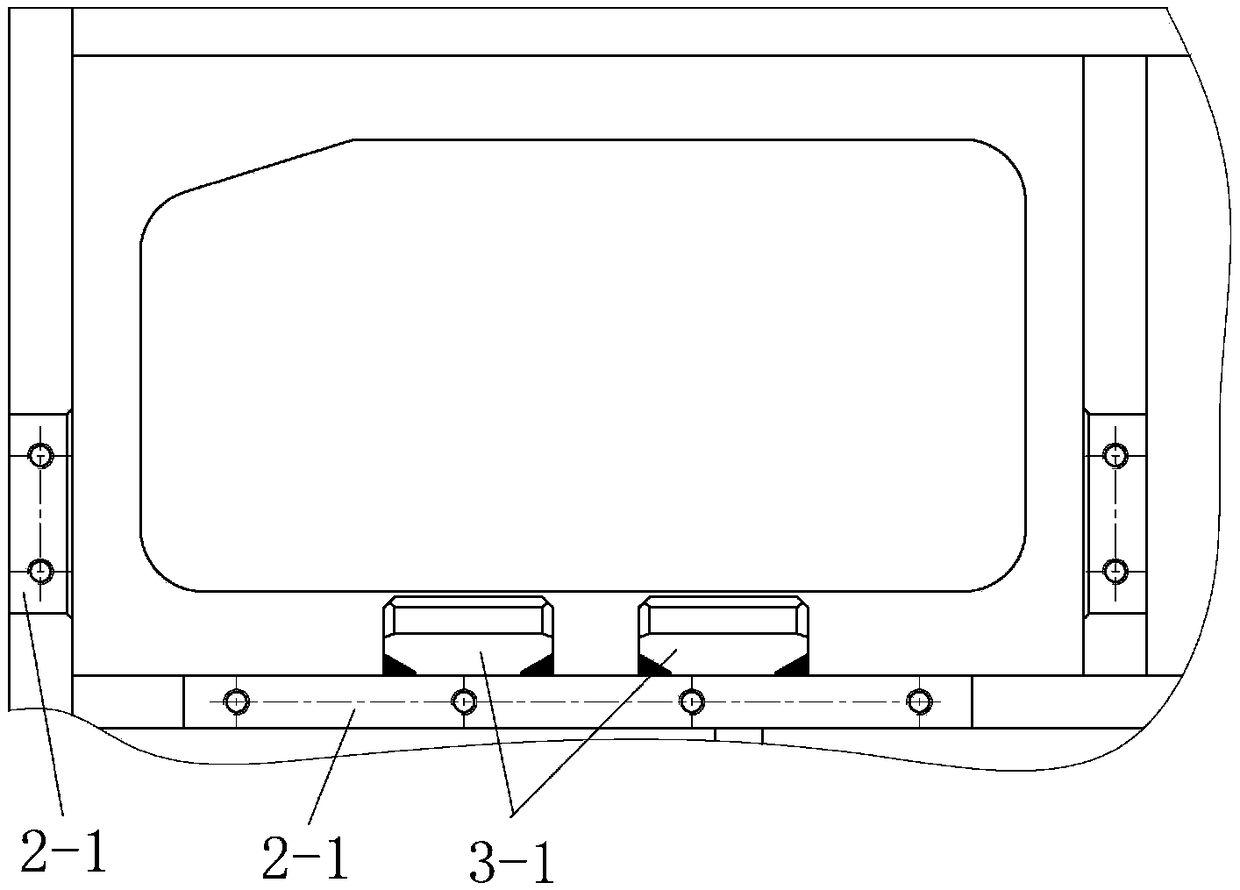

[0027] The invention discloses a method for fixing the electrical control box of a coal mining machine, such as Figure 1-3 As shown, in front of the inner bottom plate of frame 2 (corresponding to figure 2 The first guide inclined surface extending left and right is set on the left) part of the frame, behind the frame (corresponding to figure 2 The right) port part of the center is provided with a notch, and the box body 1 of the electric control box is pushed into the frame from the back to the front, so that the second guide slope extending left and right at the front end of the box body is aligned with the first guide The inclined surface is fit and pressed tightly, and the flange 1-1 located at the rear end edge of the box is just embedded in the notch 2-1 in the up, down, left, and right directions to match the notch. The front end and the rear end of the frame respectively correspond to the coal wall side and the old pond side of the shearer. The screw group used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com