Tubular electric heater

An electric heater and tubular technology, which is applied in the field of tubular electric heaters, can solve problems such as inability to produce, and achieve the effects of fast heating, stable thermal curing quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

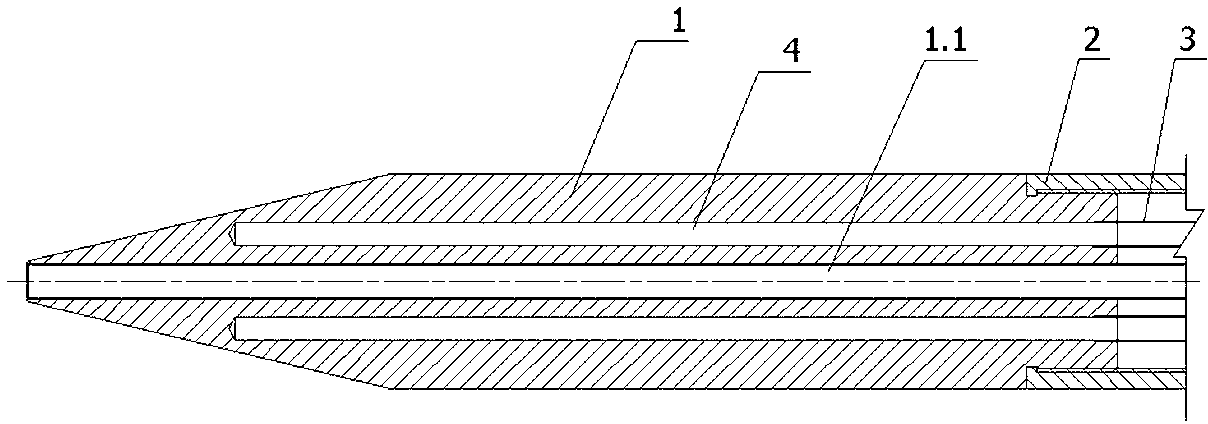

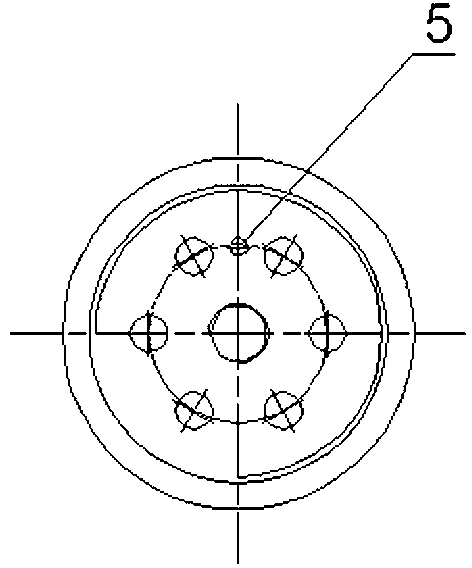

[0016] figure 1 The tubular electric heater shown is used in the production of epoxy-based pultruded mandrels, and it includes a tube body 1 , a tube joint 2 , a sheath tube 3 , a heating tube 4 and a sensor 5 . The pipe body 1 is the main component of the present invention. The component is in the shape of a thick-walled circular tube, and its outer wall is composed of a truncated cone and a cylinder. One end of the body is threaded with the pipe joint to form a positioning installation. The cross-section of the pipe body 1 is provided with an axial through hole 1.1 in the center. The non-alkali glass fiber and a part of the prepared glue enter the mold cavity through the axial through hole 1.1, and the other part of the glue enters the mold cavity along the outer wall of the pipe body 1. In order to ensure that the rubber material and alkali-free glass fiber enter the mold cavity after isothermal heating, the present invention embeds heating tubes 4 at equal intervals and c...

Embodiment 2

[0018] This embodiment is used for the production of epoxy-based pultrusion mandrels with a diameter of φ250mm. Because the product specification is larger than that of embodiment 1, the consumption of rubber and alkali-free glass fiber is more, although the structure of the tubular electric heater used is the same as that of the embodiment 1, but the main technical parameters have been adjusted. For example, the diameter of the axial through hole 1.1 built in the tube body 1 is increased to φ50 mm, the taper of the truncated cone is 1:4, and the tube body 1 is embedded with eight 1500w heating tubes 4. The tubular electric heater under this configuration is the same as The application effect of embodiment 1 is similar, and the energy consumption is only 1 / 30 of the prior art, so the application of the present invention has good economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com